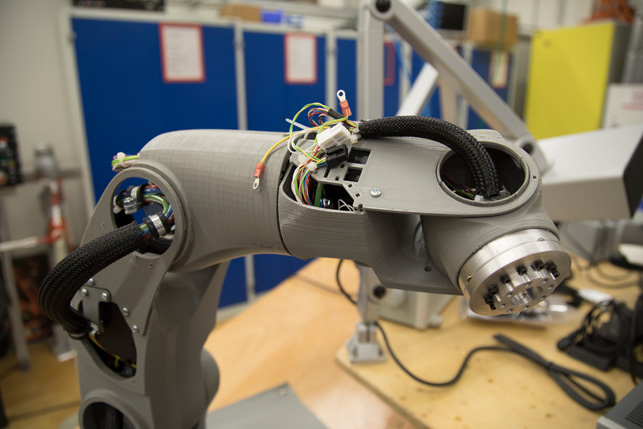

Kuka is using 3D printers from Makerbot to prototype new robots and their endeffectors

Kuka is in the business of building sophisticated industrial robots for some of the world’s smartest factories. But when it comes to equipping those robots with the arms and grippers that they need to deftly perform specialist tasks, Kuka turns to equipment from another pioneer of smart factory technology, 3D printer company MakerBot.

At the Kuka Development and Technology Center at the company’s global headquarters in Augsburg, Germany, two teams work extensively with 3D printers. The first is the Prototyping Team, which develops new robots; and the second is the Applications Engineering Team, which develops new custom applications. Both use 3D printers early and often in their design processes, with the result that the company’s MakerBot Z18 machine spends 7,000 hours in operation each year.

Recently, the use of 3D printers helped Kuka to achieve one of its fastest development cycles yet, with work on the KR 3 Agilus, a smaller scale robot designed to automate work carried out in individual cells on the manufacturing plant floor.

Building the KR 3 Agilus

Building a six-axis robot capable of performing a wide variety of tasks takes serious planning, testing and precision. At Kuka, that job falls to head of manufacturing engineering Soeren Papsdorf and his team.

Having access to an in-house 3D printer with a large build volume allows designers and engineers to print and test designs much earlier in the process than if they outsourced parts, and at significantly lower cost than if they produced metal parts in-house.

Once a final design begins to take shape, the team prints scale prototypes in order to test design features such as cable routing, a step that might otherwise take weeks. With the rich physical information available from early printed prototypes, designers can make faster and better decisions that shave weeks off total development times.

As Kuka’s design for the KR 3 Agilus approached its final form, Papsdorf’s team printed custom tooling and manufacturing set-ups for assembly and testing. By 3D printing manufacturing jigs and fixtures, and creating new iterations of these in-house, another stage in the process is streamlined by side-stepping the back-and-forth that usually goes on between clients and outsourced suppliers.

In fact, the team at Kuka credit 3D printing with speeding up the development of the KR 3 Agilus by several weeks.

The printers have a 92% success rate, even though some are working on an almost non-stop basis.

The Kuka KR 3 Agilus is ideal for small workcells and fine control applications

Helping hands

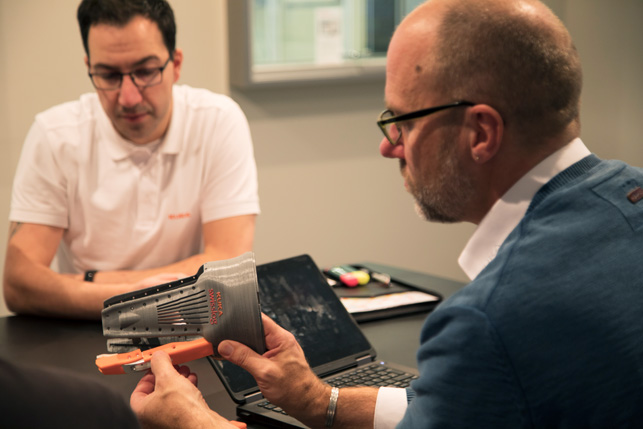

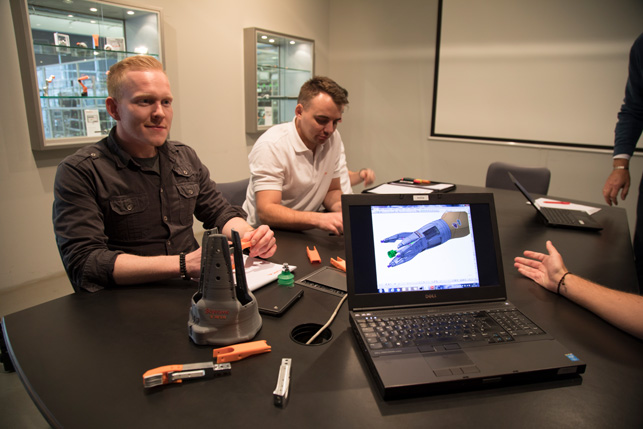

But even once a robot is built, it still needs custom end-effectors – in other words, ‘hands’ – in order to carry out specialised tasks.

Led by Otmar Honsberg, the Applications Engineering Team is responsible for adapting and equipping robots from Kuka’s growing portfolio to meet the more specific needs of individual customers, from assembling delicate consumer electronics to picking and packing easily damaged food products.

Take, for example, the Kuka LBR iiwa, a smart robot designed to safely work alongside humans: here, the end-effector must be able to dynamically identify specific objects in containers and move them.

Using 3D printing, Honsberg’s team sprinted from early concept exploration to testing prototypes, and eventually decided to use 3D printing to create the hand that would be used in production, cutting down on hardware weight and development time. The result, when paired with a camera and software, is the ItemPiQ solution, used for order picking in warehouses and distribution centres.

Once a hand is built, Honsberg’s team is then responsible for implementing the system on the customer’s own premises. Here, 3D printing gives them the ability to further customise and improve end-effectors on-site.

According to Honsberg, 3D printing gives his designers and engineers incredible freedom and makes conventional processes seem way too slow by comparison. He reckons that, in some cases, 3D printing saves between two and four weeks and allows a degree of fine-tuning that otherwise would not be possible.

As digital technologies grow in sophistication and the ‘Industry 4.0’ concept of smart, connected factories spreads, Kuka’s continued leadership will depend on the speed at which the company brings new industrial robots to market. In particular, its customers will increasingly be looking for robots that are powerful and precise, but also safe to work in close proximity to human colleagues.

With 3D printing, Kuka is well-positioned to meet the challenges that a new era of smart manufacturing will bring.

The Applications Engineering Team at Kuka is responsible for adapting and equipping robots for specific customer needs

KR 3 Agilus

Kuka’s KR 3 Agilus and LBR IIWA

The KR 3 Agilus has a payload of 3kg and is ideal for small workcells, where small components and products are manufactured. It offers a high degree of accuracy and fidelity for complex and fine-control tasks, such as assembling small components, screw fastening, adhesive bonding, packaging and inspecting. It weighs just 26kg and can be mounted on a ceiling, floor or wall.

LBR iiwa

The LBR iiwa is described by Kuka as being designed for “human-robot collaboration, or HRC.” As with other collaborative robots, from the likes of Universal Robots or Rethink Robotics, it is intended to work alongside humans, and assist them with tasks, rather than be kept behind a safety fence or in a cage.

Sensors enable it to avoid collisions and enhance human-centred operations without a great deal of risk. The LBR iiwa is available in two versions, with payload capacities of 7kg and 14kg.

Robot hands: How Kuka uses 3D printing to build new kit

Default