3D printed wheel protection jig

Speed matters in all sectors of the automotive industry, and vehicle assembly is no different – the faster the cars roll off the production line in perfect condition, the better.

Volkswagen Autoeuropa is responsible for manufacturing iconic Volkswagen models such as the Scirocco and Sharan, and annually outputs over 100,000 cars from its factory line.

Time savings are always a huge goal, but can often be found in the smallest of forms, with Volkswagen Autoeuropa (VWA) finding that desktop 3D printing can be of great value.

Prior to working with printer manufacturer Ultimaker, VWA relied on external suppliers for its tools, jigs and fixtures. These third party companies often took several weeks to process the mock-up and manufacture the tools in question – considerably holding up production, and adversely affecting the car assembly workflow.

This liftgate badge took 35 days in development time when sourced externally. With 3D printing, the project was completed in 4 days and the costs reduced

Ultimaker – Substantial savings

When designing and developing new manufacturing aids there often needs to be a trial-and-error approach, so outsourcing also proved to be expensive.

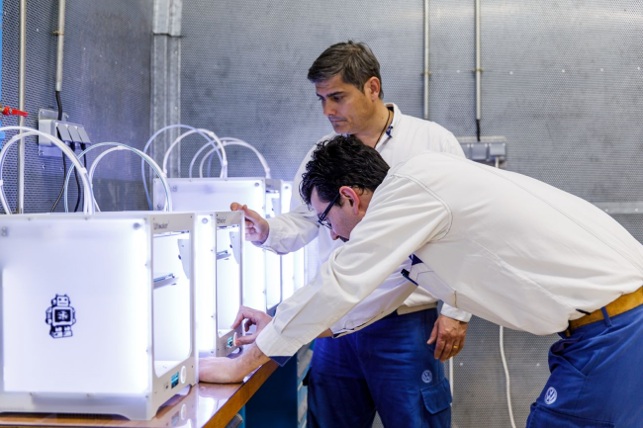

After having validated a concept in 2014, VWA currently has seven Ultimakers in operation and produces 93 per cent of all externally manufactured tools in-house.

The transition to 3D printing saved 91 per cent in tool development costs and reduced development time by 95 per cent.

This translates into savings of an estimated €150,000 over the course of 2016, a figure expected to increase to €250,000 in 2017.

As Luis Pascoa, pilot plant manager at VWA explains, the initial investment in the desktop Ultimaker machines was paid back fully in two months with the savings allowed from a handful of tools.

This window gauge can now be 3D printed at just €35. Development time shrunk from 8 to 6 days

Best practice

Tool development time has equally shrunk from 56 to 10 days – with tools printed overnight and tested the next morning on the assembly line by the operators.

Their feedback can be incorporated in consecutive design iterations until the perfect tool is made.

Manufacturing aids can now be 3D printed overnight and tested the next morning, which speeds up the development process

On top of these time and cost savings, the 3D printed tools are more ergonomic and yield greater operator engagement as feedback can more easily be incorporated into design iterations.

As a result, the 3D printed tools VWA produces in-house are now considered best practice within the Volkswagen Group, with Ultimakers adding further speed and detail to the automotive giant’s production plants.