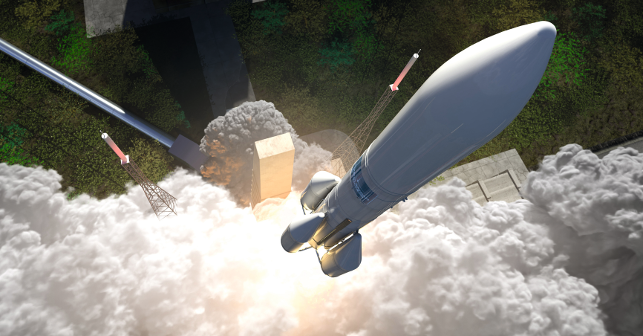

ArianeGroup has succeeded in manufacturing the injector head of the Ariane 6 VINCI upper stage propulsion module with an all-in-one design

The European Space Agency (ESA) aims to assume a strong and independent position in space transportation using efficient launch vehicle technology. In order to achieve this, ArianeGroup, a joint venture by the European aerospace company Airbus Group and the French group Safran, was commissioned by ESA to construct Ariane 6.

Ariane is a series of European launch vehicles designed to enable heavy payloads, such as communications satellites, to be put into orbit around the earth. Ariane 6, scheduled to replace the current version 5 from 2025 onwards, is designed with the intention of securing Europe‘s access to space at a competitive price.

The goal set for this project is to reduce costs by eliminating the need for public funding. The focus is on the rocket’s upper stage module, which takes over propulsion after the vehicle leaves orbit.

Core component

In a propulsion module, tremendous forces develop under extreme conditions. This demands maximum levels of reliability and precision in a small space.

The injection head is one of the core elements of the propulsion module, feeding the fuel mixture into the combustion chamber. Its traditional design consists of 248 components, produced and assembled in various manufacturing steps.

The different processing steps, such as casting, brazing, welding and drilling, result in weak points that can constitute a risk under extreme loads. Moreover, it is a time-consuming and complex process.

In the field of injector elements, conventional production requires over 8,000 cross holes to be drilled in copper sleeves that are then precisely screwed to the 122 injector elements in order to mix the hydrogen that streams through them with oxygen.

These figures clearly show that, from the perspective of risk, one functionally integrated component combining all the elements is an obvious but ambitious goal. This could also release huge economic potential and cut the number of processing steps as well as production time, especially for such a Class 1 component.

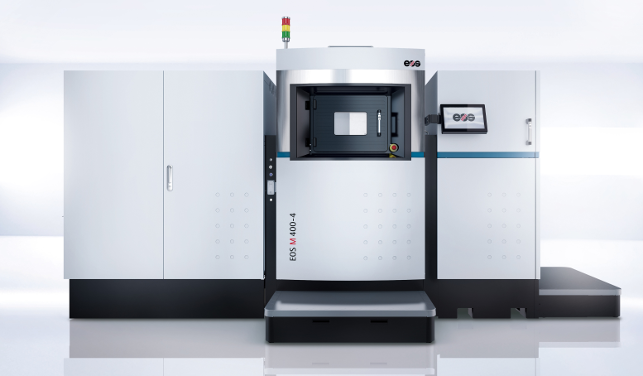

Designed for industrial applications, the EOS M 400-4 offers a large build volume of 400 x 400 x 400 mm combined with four lasers

Facing up to the challenge

The solution for these challenges is provided by additive manufacturing. “Only additive manufacturing can combine integrated functionality, lightweight construction, a simpler design, and shorter lead times in a single component,” says Dr. Steffen Beyer, head of production technology – Materials & Processes at ArianeGroup.

Utilising EOS technology, the project team again chose a heat- and corrosion-resistant nickel-based alloy (IN718) as the material. This material provides excellent tensile, endurance, creep and fracture strength at high temperatures and will also be used with the new production technology.

“After successfully developing the component, we turned our attention to cost efficiency,” reports Dr. Fabian Riss, a member of the production technology team – Materials & Processes.

The key requirement from ArianeGroup was to reduce lead times and unit costs. Manufacturing was initially performed by an incremental process with the EOS M 290. But after successful pilot tests, production was scaled up to the larger EOS M 400-4 system. Four-laser technology allowed the propulsion module component to be manufactured up to four times as fast.

“Scaling up the construction process to the highproductivity EOS M 400-4 system was an important step for us in order to advance the industrialisation and competitiveness of the Ariane 6 project.

“The collaboration unfolded very efficiently thanks to the experience and industry expertise of EOS staff. The results speak for themselves and are proof of great team performance,” adds Dr. Beyer.

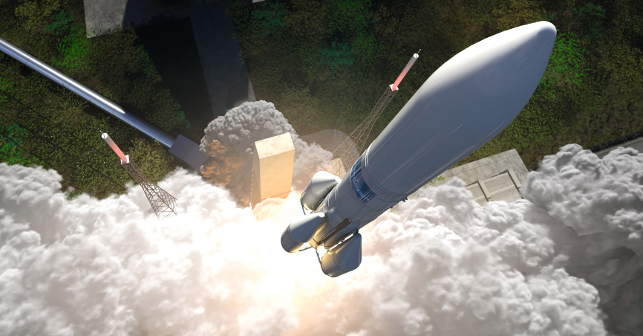

The additively manufactured baseplate of the injector head of a rocket engine with 122 injection elements is made from EOS NickelAlloy IN718

Impressive results

Using additive manufacturing a component that originally consisted of 248 parts, now consists of just one – with the same functionality, and cutting the required time down to a minimum.

The powder bed-based, industrial 3D printing technology from EOS meant that it was possible, for example, to print the 122 injection nozzles, the base and front plates, and the distribution dome with the corresponding feed pipes for the hydrogen and oxygen fuels as one integrated component.

The EOS M 400-4 multi-laser system was able to cut construction time by a factor of three and costs by 50 per cent in the example of the all-in-one (AiO) injector head.

The simplified design and the improved material properties compared with the quality of cast parts allowed the additive technology to reduce the wall thickness considerably – without losing any strength. Cutting weight by 25 per cent also meant a further reduction in construction time and, of course, costs.

Last but not least, additive manufacturing processes allow innovation cycles to be sped up significantly.

Structural improvements, design modifications, and the manufacture of test components in the development phase can be put directly into production based on CAD data without requiring engineers to spend time preparing tools, as is the case when casting parts. Whereas each iteration generally used to require around half a year, one iteration now only takes a few days. On top of this, the entire manufacturing chain now unfolds inhouse on ArianeGroup’s premises.