One of the many highlights of DEVELOP3D Live was the talk by inventor Mark Sanders. His enthusiasm and passion for what he does was clearly demonstrated not least of all when he wheeled his Strida bicycle onto the stage, unfolded it and presently got on.

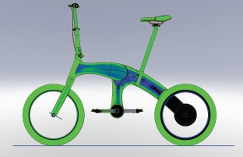

Mark Sanders and his colleague, Derek Roberts, produced this concept of the Mando Footloose e-bike in SolidWorks a year ago.

“This was the first bicycle I invented. It may look odd but all the contact points are in the right places. Trust me, I’m an inventor and I’ll show you,” uttered Sanders as he cycled round the stage.

Principal of MAS Design, a company he set up in the UK 27 years ago, Sanders has always been fascinated with bicycles. Although they were invented over 100 years ago, he still feels there is a great amount of innovation they can bring to the world.

“Bikes are just the perfect human amplifiers. For the same amount of energy as it takes to walk, you can go four times faster and four times the distance,” he says.

As well as bike design, especially the folding kind, he has also created a variety of other products from golf carts and medical equipment to industrial valves and kitchen gadgets. “I’m half designer/half engineer and I love to work on mechanical stuff that also has a big aesthetic side.”

Having initially trained as a mechanical engineer at Imperial College in London, which was sponsored by a Rolls-Royce company, he enrolled onto the industrial design engineering course at London’s Royal College of Art (RCA).

As his final year project he created an innovative folding, triangular bicycle that 25 years later would still be in production. It was the Strida.

Just roll with it

The idea for the Strida came about through his own experience and the 22 mile commute he had to take to the RCA from his home in Windsor everyday.

All means of transport involved some degree of hassle and although cycling to the train station, getting on the train and cycling away at the other end seemed the best option, bicycles were cumbersome objects. “At the time taking full-sized bikes on crowded commuter trains and buses just did not work well.

Folding bikes were in their infancy and all were heavy and complex: they were usually just ‘fold in half jobs’,” says Sanders.

Taking inspiration from the original McLaren baby buggy, which looked like a walking stick with wheels on the end when folded, he set about creating a compact, portable and fun folding bicycle.

After numerous sketches and models he engineered a triangular frame that consisted essentially of three tubes with wheels at its corners.

When launched in 1987 the Strida received mixed reviews with some deeming it a bit too wacky whilst others applauded it for its original design and ease of use. DEVELOP3D’s very own Martyn Day is one of the latter who has been cycling the streets of Oxford on his Strida for over 12 years.

The Strida is now on mark five and is manufactured by a Taiwanese company with its biggest market being in the Far East.

Since that inaugural product, Sanders has been involved in a number of other folding bicycle projects some of which have never taken off like the X-Bike for Sir Clive Sinclair, an English inventor, and others that are selling well like the iF Mode range.

However, for the first time he is applying his skills of designing folding mechanisms to the e-bike market in the form of the Mando Footloose.

New way of moving

Showcased at Eurobike 2012, which took place in Friedrichshafen, Germany, at the end of August, this chainless e-bike from Mando, a South Korean automotive parts manufacturer, features the latest automotive technologies in a minimal and contemporary form.

“Mando had this bold concept for a bicycle as they realised that there isn’t much future in traffic clogged cities especially as their home town of Seoul is just one big car park,” comments Sanders.

“With expertise in motors and gears they researched different drive systems and technologies and came up with a hybrid system where the pedals drive an alternator, which can then add and range extend the battery of an electric bike.

So, they found that by taking away the chain and doing everything by an electrical signal, it effectively means that the bike is ‘pedal by wire’ with all the control coming from a central ECU [electronic control unit] that the user can programme to either have a workout by pedalling (and in so doing charge the battery) or letting the bike do all the work.”

With further integration of technology from the automotive industry such as sensors for easy handling and two-speed auto shifting, Mando built a test rig that demonstrated that the concept did indeed work.

But being an engineering company, they needed a designer to come onboard to give it shape and form. Due to his vast experience as a bicycle designer, Sanders was approached just over a year ago.

“I was enticed by the benefits of a hybrid e-bike and this step-jump in technology is what made the project so fascinating. I joined without hesitation.”

His aim was to give it a visual identity that reflected Mando’s aim of making personal transport more accessible. He felt that an organic shape would give it just such a friendly and non-threatening persona in order to lure commuters out of their cars.

Taking shape

So, knowing what all the key parameters of the e-bike were, Sanders set to work creating a form around them.

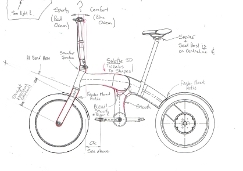

He started how he does all his projects by printing out the parameters in SolidWorks and then sketching over the top of them. “It’s a process I just love using because you can get the forms much faster than trying to sculpturally model,” he explains.

He presented his concept to senior Mando management at Eurobike 2011, who were all very enthusiastic about it. Sanders then spent a great deal of time over in Seoul working alongside its engineers.

This was an unusual project for him in that he was essentially the design consultant working on the styling whereas usually he is far more involved in the engineering. “This project was 80 per cent aesthetics and only 20 per cent did I get to interfere with the engineering,” he laughs.

The first thing they needed to do was define the shape and this was a challenge in itself with Sanders being proficient in SolidWorks but Mando only having seats of Catia. Not only could they not input files from SolidWorks into Catia but the engineers predominantly use it to create prismatic rather than sculptural forms.

“I ended up sitting on their shoulders showing them how to make lofts and sculptural shapes in a programme I didn’t know that well but which they knew but didn’t know how to do surface work,” he explains.

Smooth operator

When they couldn’t progress beyond a level where the surfaces were not curvature continuous, in other words perfectly smooth, Mando invested in a module within Catia called ‘Imagine & Shape’.

“When I saw this module my jaw dropped to the floor – it is designer’s heaven,” enthuses Sanders. “You import something very crudely modelled in conventional techniques, like lofting, into the module.

Firstly, it smooths out any bad shapes and secondly, it puts a 3D skeleton around the form and allows you in real-time to tweak it in a very intuitive way. So, it allowed us to get those shapes not only as I wanted them but also perfectly curvature continuous. It’s absolute genius!”

Following extensive FEA analysis in Catia and real-life testing, pre-production bikes were produced, 50 of which were showcased at Eurobike 2012. “In one year they got it together and it’s now ready for production.

That’s incredible,” says Sanders. A Korean factory has been set up to manufacture the e-bike, which will initially go on sale in Korea later this year and in Europe in 2013.

The inventor’s life

This project was actually the first time Sanders had worked as a consultant on a fee basis for more than six years. Being an inventor, the way he tends to work is to come up with a product and then try sell it to a manufacturer.

Mark Sanders during his presentation at DEVELOP3D Live in March 2012

Alternatively, he asks manufacturers what products they’d like to market but can’t work out how to design and engineer and he will then work on a solution for them.

“Some I can’t work out but some of the stuff I have been thrown at like the OneTouch can and jar openers and some of the stuff I’ve done for Joseph Joseph have worked out well,” says Sanders.

His relationship with Joseph Joseph, a UK kitchen products company set up by twin brothers in 2003, started with the Chop2Pot (see below) back in 2005.

The way the company works with Sanders, as well as with other designers, is if the product goes into production the designer gets royalties. “It is a bit like inventing to order and it’s a great way of working

because you share the upfront risks,” says Sanders.

“So, its a win win situation unless of course when it goes to the shop and for whatever reason doesn’t sell, it then gets chopped.”

But such is the life of an inventor, you just have to get up, dust yourself off and carry on. “I have projects that I’ve spent years on which have gone nowhere from things to make orange juice through to peelers and whisks.

I suppose it’s where you need financial security from projects that do sell to be able to cut the peaks and fill in the troughs.”

Copy cats

Another disadvantage of his chosen career is contending with cheap knock-offs of the products that took blood, sweat and tears to bring to life. “There are a lot fakes of Strida made.

There are three or four state sponsored factories in China that churn them out. So, if you add those to the relatively small quantity of Stridas that are officially made it means that it’s one of the most made folding bikes with 50,000 produced a year,” says Sanders.

”Although I don’t really mind Stridas being ripped off, as they are mainly sold in China and it’s a back handed compliment in a way, the can and jar openers were such tough projects that to see fakes of those really feels like someone has nicked one of my kids.” And although the products are patented, they are maintained by the company that manufactures and markets them so there is not very much he can do.

But being Mark Sanders he remains ever optimistic and practically fizzes with excitement as he talks about upcoming projects: “I’m still obsessed with bikes and folding bikes so there is more of that in the pipeline.

There is also a wicked product with Joseph Joseph that will be out in the next six months to a year. It comprises my love of kitchen products, ergonomics and at the core is a really cool mechanism.”

Chute and score

The Chop2Pot is a rather ingenious chopping board that when flat is a surface on which food can be chopped and sliced but when the handle is squeezed, the sides fold up and it transforms into a chute to easily pour or guide the food into a pot.

“The product contains six hinges and the core engineering invention is the fact that when you have two hinges crossing each other, only one hinge will flex at a time so it gives this snap action between cutting board and chute,” describes Sanders.

It was a self motivated project that Sanders designed and engineered himself. Although it originally sold in a variety of locations, in the end the company who produced it only supplied it to one shop in the world – the museum shop in New York’s Museum of Modern Art (MOMA). And it was here where Richard Joseph, one half of Joseph Joseph, picked it up in 2004 and changed both their fortunes.

“The Chop2Pot was for both of us a really pivotal project because when we first met they were in the business of making worktop savers, which were basically glass chopping boards, and they were selling them around the world but in fairly limited volumes.

With the Chop2Pot made of polypropylene I introduced them to a Taiwanese plastics manufacturer I’d used in previous bicycle projects and it started them off using plastic. As they say, the rest is history,” smiles Sanders.

Mark Sanders’ chainless folding e-bike

Default