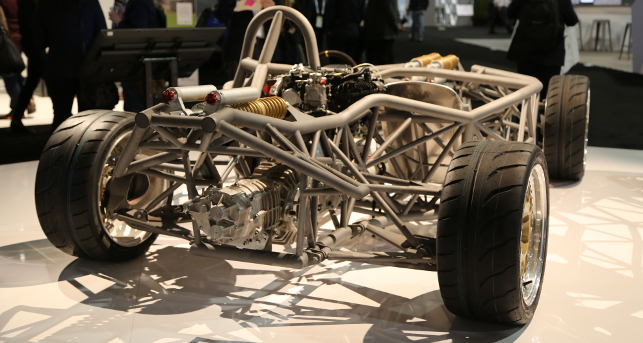

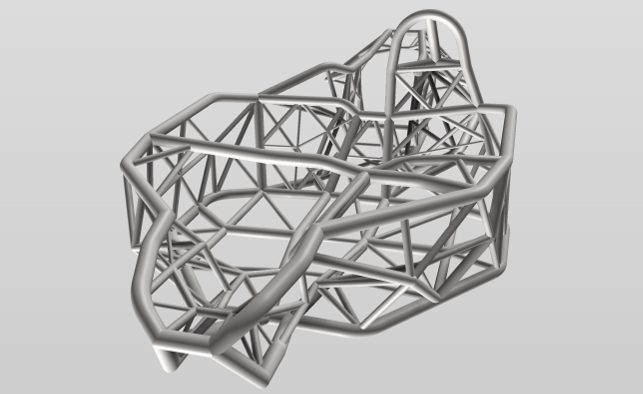

The second generation of the La Bandita’s chassis. The La Bandita is Hackrod’s high-performance sports car and proof of concept demonstrating the key elements of the Hackrod platform

The two ‘garage bandits’ are Mouse McCoy and Felix Holst. One has spent most of his life driving fast vehicles whilst the other knows a thing or two about designing them. Not averse to taking risks, the pair, who refer to themselves as dreamers and futurists, saw an opportunity to disrupt the status quo and so threw themselves into a new startup.

They aim to develop a manufacturing platform (see boxout below) that brings new technologies and processes together. “We are going to build a cloud-based engine that is going to drive the next industrial revolution,” says McCoy. “An engine that can reimagine the way that hardware products are designed and engineered, made and distributed.”

A pretty ambitious vision so let’s backtrack three years to what set them off on this path.

Meeting of kindred spirits

McCoy has been racing his whole life: “I started racing motorcycles when I was a little bitty kid and Mouse McCoy was my kid racer name [his real name is Mike].” From motorcycle racer to stuntman he then moved into producing and directing and founded entertainment studio Bandito Brothers. A notable box office feature film McCoy directed was ‘Act of Valor’, which was released in 2012.

Meanwhile, Holst had completed his industrial design degree at the University of Northumbria in Newcastle, UK, and was planning on doing a masters in car design at the Royal College of Art (RCA). That was until he spotted a job advert that piqued his interest.

“While I was preparing my portfolio for the RCA I answered an ad in Design Week back in 1996 for a temporary designer at Hot Wheels UK. At the time I thought, ‘Holy shit, Hot Wheels – are they still around?’”

“I landed a six month contract and realised that not only was I a really good toy designer naturally, but also it was far more fun designing toy cars than designing door handles at an automotive company every day of my life. So, apart from a few years at the end of the 1990s to be in a band, I stuck with Mattel and Hot Wheels until 2015 when I left,” explains Holst.

Up until 2011, Holst, who by this time was head of design at Hot Wheels globally and had relocated to Los Angeles, was responsible for the design of toy race cars but in an initiative to reinvent the brand, Hot Wheels decided to create life-size versions of these cars to race in a series of automotive media stunts. To bring this ‘Hot Wheels for Real’ campaign to life it commissioned McCoy’s studio Bandito Brothers.

The design process of the La Bandita kicked off with sketches

The team then moved onto renders

Hot Wheels for real

McCoy and Holst worked alongside their teams to create enormous custom-built orange tracks, including a 100-foot ramp and a 60-foot double loop, as well as the prototype replica cars that the stunt drivers would race. It was an ambitious and daring spectacle that broke records and won awards (just Google YouTube videos of ‘Hot Wheels Double Loop Dare’).

“We were building these cars in a secret facility in radically short time frames with a lot of risk involved. We could have started thinking we were pretty cool but I was like ‘Dude, I think we kinda suck’,” admits McCoy.

“We pulled everything off, we didn’t scratch or hurt anybody and our margins were really thin but our tech was from the 60s. It took a lot of balls, brains and wizardry from the engineers and the guys who knew how to build this shit but we were doing it pretty much old school.” Holst adds, “High tech for us was a GoPro with some ribbons tied to the roll cage so when the driver did the jumps we could see what the air was doing inside the car.”

The La Bandita’s form has been developed using Autodesk Fusion 360

The future of making things

With a new film project on the horizon for which he needed to build 40 to 50 prototype cars, McCoy decided to set himself on a mission to discover what the future of making things looks like. Having come across Autodesk through the visual effects work he’d done previously, he decided they would be a good starting point to learn about new technology and so knocked on their door.

“I met all the right dudes at the right time. They really pulled the curtain back for me and I started to see glimpses of what the future looked like,” says McCoy.

As well as Autodesk, he also engaged with America Makes, an Ohio-based accelerator for additive manufacturing (AM) and 3D printing. “I was well positioned in the government after one of my projects so got introduced to all of those guys too.

“I was in San Francisco, but I spent a lot of time with the America Makes folks thinking about large scale additive and what that would mean for large scale prototyping,” comments McCoy.

After about six months to a year in San Francisco he called on Holst, “Dude, I’m seeing all this shit that’s like science fiction – it’s crazy,” and beckoned him to come see it for himself.

“I went along with it,” says Holst. “After all that we’d been through I thought McCoy’s not feeding me with bullshit and there’s got to be something at the end of this rainbow.

“So I quit Hot Wheels and got on a plane. When we walked into Autodesk we saw one of the first interactions of their generative design research project called Dreamcatcher, which at the time was just starting, and we looked at each other and said ‘Dude, imagine using this to make a car chassis’. From that point it was game on.” McCoy adds, “We got to a point, as Felix said, where we saw the first sketches of generative design and the first bits of additive and said ‘Holy shit, these learning trends – VR, AR, generative design, machine learning, simulation, additive manufacturing, crowd, cloud and IoT – what happens if we start to aggregate these things, start to connect some dots?’ If this shit is for real, then it starts to mean that a kid with a dream, like we had with Hot Wheels for Real, or three kids in a garage who want to start a car company or a large industrial company, can.

“If three kids wanted to start a software company, you’d say ‘Hmmm, Amazon web services, connected world. Sure.’ But if those same kids wanted to start a car company, you’re told you’re not allowed to play. Fuck that.”

The pair embarked on a deep dive research project with Autodesk to see whether they could indeed connect the dots and placed themselves as those kids in a dorm room with the ambition of starting a car company.

Shredding the chassis through California’s Mojave Desert in order to capture the real-time data and force loads

Capturing force loads in the desert

The first step in creating their high-performance sports car, which they called La Bandita speedster, was capturing the data to feed into Project Dreamcatcher’s generative design engine. To do this they needed an existing chassis and having access to some of the best race car builders in the world, this wasn’t a big ask. The resulting chassis weighed in at 470 pounds, which gave them their target to beat.

The chassis was scanned and the 3D model uploaded to the cloud. It was then wired with hundreds of sensors to capture the real-time data and shredded through California’s Mojave Desert. “Mouse did literally drive the wheels off that car so we knew our data was good as we had pushed it to the absolute limit,” says Holst.

The result was some millions of data points about the car’s structure and the forces acting on it, which were then plugged into Project Dreamcatcher and applied to the 3D model in the cloud. Here the software uses machine learning to generate multiple design options by evaluating design trade-offs.

Mouse McCoy and Felix Holst, Hackrod’s co-founders

“The big thing that cloud processing has given us is the ability to now tackle millions and millions of calculations per second. Before it would have taken a lot of engineers a long time to work through this complex math,” says Holst.

With the interior chassis evolving, Holst set to work on the speedster’s exterior design and recruited his old partner in crime from Hot Wheels, Fraser Campbell, to help him in this task. They moved from napkin sketches into Autodesk Fusion 360 and although they were following the narrative of being kids in a dorm room, they knew full well that their idea of a dream car would not be theirs.

“We are not ashamed that we are from a different generation to those kids. This is the car that we aspire to have. The idea is to tie us into the ethos of the early speedsters – basically a four-wheel motorcycle with one purpose: to go fast and stay light,” says Holst.

Fraser Campbell, a colleague from Felix Holst’s Hot Wheels days, was recruited to help on the design of the La Bandita speedster

All the surfacing and design review was then carried out in multi-person, multi-location VR with the various team members interacting with a life-size model of the car in a photorealistic experience.

“We’ve been working with a modeller in Buenos Aires, Argentina. We would record our sessions in a virtual realm and when he woke in the morning he could watch the recording as if he had been there in person anyway and make all the changes to the surfacing.

“It’s super quick. When you start going down the rabbit hole of what these new technologies offer beyond the immediate benefits, it’s phenomenal. It’s a whole new way of working,” describes Holst.

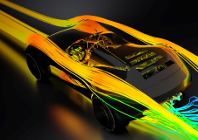

This of course meant that they didn’t make any clay models as you would in a traditional automotive design process. Additionally, all simulations and testing were performed digitally too. “A wind tunnel could cost you $35 million but a monthly cloud subscription is $35 and it will run all your CFD and flow analysis in the cloud.

Dr Slade Gardner, who previously worked at Lockheed Martin, has joined the Hackrod team as chief technology officer

“What was radical about this process is that we went from sketch to rendering to a complete ready-to-manufacture design in a matter of weeks. This completely collapses the trajectory of two-year design cycles. We just achieved what the biggest car companies do in a fraction of the time,”comments McCoy.

Getting it made

For this first generatively designed chassis Hackrod wanted to manufacture it using the same technique and materials as the original. A hot-rod fabrication shop in LA was able to custom weld the 300 tubes in the chassis using chromoly (chromium-molydenum steel) and the result was a 25 per cent weight saving.

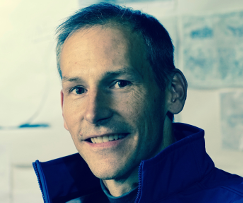

A rendering that reveals the generatively designed chassis

Although this validates their process in that a lighter but structurally superior design can be achieved, they ultimately aim to utilise AM as the manufacturing process.

This will not only be cheaper (it’s just as cost eff ective to print one off as it is a 100 as there is no tooling involved) but also means that complex parts and shapes can be printed.

“The part you design doesn’t have to be compromised for a hundred year old production method. Up until now, everything we ever made had to still talk within the parameters of draft angles and cutting paths but now the part comes out exactly as designed rather than compromised by any adjustments for the manufacturing methodology,” says Holst.

As for the other components, this will be managed through a cloud-based supply chain. “What we see happening is a new world of distributed manufacturing and local assembly where you pass components out and different factories around the country will make them and send them back to you very quickly for local assembly whether in a workshop or in a membership-based tech shop,” adds Holst.

A model of the chassis that was created using Autodesk’s generative design tool Project Dreamcatcher

To lend expertise on the manufacturing side and to head up Hack Rod’s technical vision, the pair have brought a new team member onboard – Dr Slade Gardner. Having previously been a Fellow at Lockheed Martin Space Systems and a Fellow at Lockheed Martin Aeronautics in the Skunk Works division, Gardner is a foremost expert in industrial additive as well as being a materials scientist.

“Slade wanted to do something more radical than what he was doing at Lockheed Martin, which is saying a lot, and so joined our little startup,” says Holst.

As we go to press, the Hackrod team are currently starting to explore the AM process required to build the next evolutionary stage of the car’s chassis. According to Holst, they will print a full size generatively designed chassis, optimised for additive manufacture in aluminium using metal deposition printing on a 15’ bed. The aim is to have this part of the project completed by October 2017. Also, the next generation of the Bandita will not be burning fossil fuels but rather a hacked Tesla powertrain.

The big plan

Essentially Hack Rod is working towards creating a cloud-based manufacturing platform that democratises manufacturing enabling anyone to create, design and build what they want. “When asked for a description of our startup, we say we want to be the Red Bull of manufacturing. We want to build radical stuff using new tools and then make these tools accessible to everyone,” says McCoy.

The La Bandita chassis was manufactured using the same materials and techniques as the original in order to demonstrate the weight savings gained

Holst adds, “What we are doing could be dominated by the big corporations and go towards making them even more money or we could go in, cause a bit of a fuss and carve a big chunk out for the every man and build new industry, new innovation.

“And that is such a big part of what we are doing – powered by the notion that all of the biggest inventions in history didn’t come out of big corporations, the came out of garages and dorm rooms.”

The key elements of the Hack Rod platform

Engineered with generative design using cloud processing

Generative design uses machine learning or artificial intelligence (AI) to process information. So the user sets goals (such as size, weight, strength, style, materials, cost etc.) and then utilising the power of cloud computing the software will create thousands of new design solutions.

These calculations would take a human infinitely longer to achieve and provides a smart solution that is lighter, quicker to develop, uses less material and costs less to manufacture.

Designed in VR

Developments in virtual reality now mean that teams can work together in different locations on the same 3D model. Lifesize components can be adjusted and scrutinised in a photorealistic experience. This means that no prototypes need to be made. With a cloud subscription, simulations and analysis can easily be carried out to refine the design further, foregoing the need for a wind tunnel.

Made using advanced manufacturing

Once you’ve chosen your design and lived in the virtual world with it — for instance, with VR gaming, you could even race it virtually and get others in your community to test it too — then hit the ‘make’ button and have it manufactured using additive manufacturing techniques.

Delivered by the supply chain of the future

There is no longer any need to invest in factory infrastructure — by sourcing components through a distributed manufacturing process, users can have components made by different suppliers and then either assemble themselves locally in a workshop or at a tech shop.

Meet the renegades taking on the world of automotive design

Default