Amazone look to lightweight parts with Altair Inspire optimisation tools and Voxeljet additive manufacturing to assess the future of its agricultural machinery

Amazone, founded in 1883 in Germany and still a family owned company, manufactures a wide range of agricultural machinery. It goes without saying that, as these products are subjected to harsh and varying conditions, they need to be robust, durable and yet competitively priced.

Amazone recently conducted a project in which a formerly welded rocker arm, part of a soil tillage unit known as Catros-2TS, was subjected to optimisation to evaluate the part’s material usage and durability.

This rocker arm is a complex part weighing in at 245kg, including a total of 16.5 m of weld seams needed to join the single parts. This amount of welding made production very time and cost intensive.

Amazone’s engineers decided to take a closer look at its design and assess the potential for making the part lighter but also stiffer and more durable.

In the first instance, Amazone’s engineers realised that a move from welding to casting would offer several advantages. Since the component can be cast in one piece and needs no welds, production would be much simpler and the process less error prone.

From welding to casting

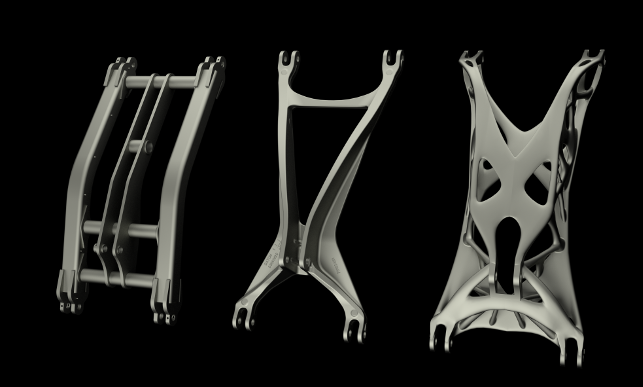

To get to a new design for the casted part, Amazone conducted a topology optimisation. To optimise the structure, the engineers used solidThinking Inspire from Altair, a global developer of simulation technology.

First, they defined the possible design space and the boundary conditions, such as loads, required stiffness, and manufacturing restrictions. Non-design space areas were determined as well, where the structure must not be modified, for example at support points or cylinder connections. With these inputs, the software calculated how much material was needed, at which position, to meet requirements such as structural strength.

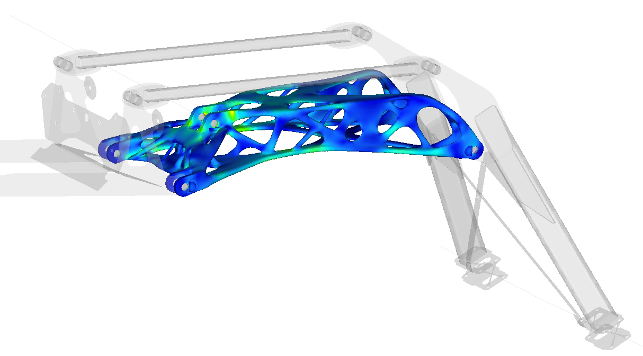

From the optimisation result, the engineers created a detailed design that was then evaluated in an FE analysis with OptiStruct. When compared to the welded construction, the casted version featured lower weight and fewer stiffness variations.

The overall loading in the casted material of the new design was significantly lower compared to the loadings in the weld seams of the original assembly. Due to the loadspecific structure of the casting part, subsequent physical tests showed increased durability by a factor of 2.5 while the weight was reduced by 8 per cent.

The new version of the rocker arm component is already in operation and Amazone claims that it has reduced manufacturing costs by one third compared to the formerly welded construction. Also, as the casting mould is reusable, tooling costs were quickly amortised.

Leveraging 3D printing at Amazone

Impressed by the results achieved with this redesign, Amazone’s engineers looked to make even further improvements. Additive manufacturing or the combination of additive manufacturing and casting could potentially provide

even better results. So the project was been taken a step further.

Altair, 3D printer manufacturer voxeljet and material supplier Procast Guss supported Amazone in this study and jointly created a technology demonstrator of the rocker arm, using a new process Altair and voxeljet had created to combine the advantages of 3D printing and casting.

Components produced with this process offer significant performance improvements and the solid potential for serial manufacturing and mass production. Bringing design optimisation, fill and solidification analysis, casting, and 3D printing together addresses the challenges of lightweight design in a new way and enables the set up of an innovative design and manufacturing process that enhances performance and efficiency.

In this combined process additive manufacturing is used to print a casting mould, which offers a higher design freedom compared to traditional methods used in producing such moulds.

Topology and casting simulation

The first step was a new topology optimisation. The design space was defined and loads were derived from a motion analysis with Inspire and then applied to the model.

After running the optimisation, which also took manufacturability into account, the new part resulted in a further weight saving of about 11 per cent, while keeping durability and stiffness at the same level as with the casted part.

To make sure that the new design could be cast, the engineers also conducted a casting simulation with solidThinking’s Click2Cast (C2C) tool. C2C was used at two points.

In the early phase, C2C allowed designers to test the manufacturability of the component design and optimise it, avoiding internal defects and analysing critical areas while also reducing iterations between the design and production departments.

At the end of the design phase, C2C was used again to simulate the full mould filling process and thermal solidification, helping create the most efficient manufacturing method and guaranteeing a controlled filling process for increased quality and so minimising any waste in energy, time and material.

Reduce turbulence

Turbulence is always a factor in the flow of molten metal as it can trap gases in the casting material and cause defects.

It can be reduced by the design of a gating system that promotes a more laminar flow of the liquid metal.

With the aid of simulation and 3D printing in combination, almost any shape is possible and this reduces the risk of casting defects. As a result, a controlled fill is ensured which prevents oxidation of the alloy due to turbulence during the filling process and improves casting quality further.

In the next step, Voxeljet had to produce all the tooling (cope, drag, and mould) for the casting process. Before printing, a digital core and mould set was designed for the optimised demonstrator. The final cast set consisted of only four pieces.

All pieces were then 3D printed in silica sand, using a VX4000 printer with a build envelope of 4.000 x 2.000 x 1.000 mm. Once all pieces were printed, they were now ready for the casting process.

Within a few days, the mould set was printed, packed and shipped to Procast Guss. With a production capacity of 40,000 tonnes of casted products Procast Guss produces unit weights of 0,5 – 350 kg of machine moulded castings.

The range of cast iron materials offered by the company varies from grey cast iron and spheroidal cast iron to SiMo and ADI to highly alloyed austenitic or wear-resistant materials.

The material used in this process was the EN GJS 500 -14 cast iron. Procast Guss applied a die coating to receive a smoother surface before the actual casting process. It then combined the four parts into one mould.

After the part was cast, final manual adjustments were made like separating the non-essential parts, left over from the casting process, from the final component. Finally the entire part was cleaned to receive an optimum result.

The new rocker arm, printed and cast for the first time as a demonstrator in real size and ready to go has a weight of only 200kg, which is another 11 per cent less than the traditionally casted part. At the same time, the new rocker arm is as stiff and durable as the traditional cast part.

The project partners hope that this demonstrator will show that 3D printing in combination with both topology and casting simulation is an extremely powerful tool offering improved part quality as well as assuring an energy and material efficient production process.