The Lucid Air is an all-electric luxury sedan that cuts an elegant exterior with a deceptively spacious interior, which the compact powertrain allows. It took just two years to develop and, as Tanya Weaver discovers, this involved a largely digital design and engineering process that hinged on team collaboration

Our traditional view of what a car should look like is largely based around the combustion engine. A reasonable sized bonnet or hood houses the inner workings, a grille protects the radiator and engine and admits cooling air, and then an exhaust pipe or two at the rear spurts out all the emissions.

But with electric drivetrain technology auto manufacturers can now break free from the shackles of the combustion engine. It provides the opportunity to layout and proportion a vehicle completely differently.

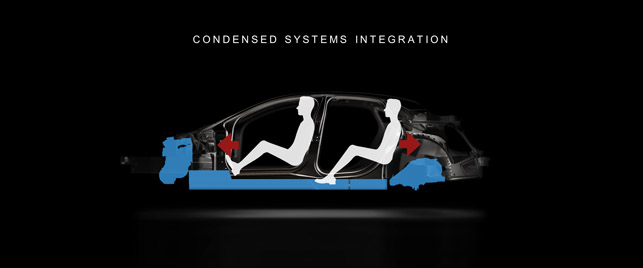

For instance, electric motors, batteries and accompanying electronic components are nowadays much more compact, meaning increased freedom to create a larger interior in relation to a car’s footprint.

This is exactly what Silicon Valley start-up Lucid Motors is showcasing with its first vehicle – the Lucid Air. Unveiled at the end of 2016, this all-electric luxury sedan uses a twin-motor four-wheel drive powertrain that is capable of accelerating from 0 to 60mph in less than 2.5 seconds.

Performance aside, a standout feature is the long, sleek cabin that inside is claimed to be comparable to a Mercedes S-Class despite the car itself being only a little larger than a Mercedes E-Class.

Lucid – Electric battery heritage

Although Lucid Motors seems to have launched itself onto the automotive stage from nowhere, it in fact has been around for over ten years but in the guise of EV powertrain developer Atieva. With its batteries having logged millions of accumulated miles and with major backing from Chinese investors, in 2014 Atieva announced it would be developing its own luxury vehicle. It then placed Ian Rawlinson at the helm as chief technology officer to help it chart this new course.

No stranger to electric vehicle design having formerly worked as chief engineer for Tesla’s S Model, Rawlinson’s vision was to create a car that really optimised occupant space and have that reflected in its design language.

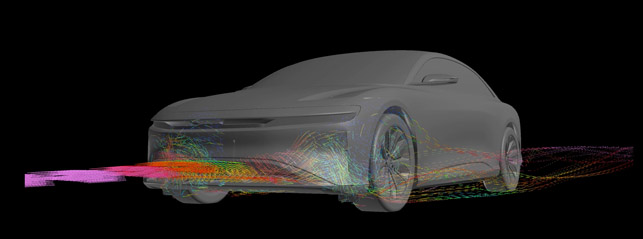

“The initial inspiration came from aircraft, which we felt is a very honest form of design. It’s not screaming aggressively at you that it’s fast, it just is because of its shape. So we really focussed on making a car that is very seamless, elegant and effortlessly sleek,” describes Lucid Motors’ vice president of design Derek Jenkins, who has been the design lead on a variety of vehicle programmes at Audi, VW and Mazda.

Lucid – Building a team

A two year time frame in which to develop a car is ambitious enough but especially so with no heritage, legacy data or established product development processes to build upon.

But it was this that actually appealed the most to Jenkins when he was approached to join the company.

“In my experience in the traditional car business so much of your energy as a designer goes towards how to evolve the image of a particular company. But when I came to Lucid it was about identifying who our target consumer is, what their trigger points are, where we want to be viewed in three to five years and then building a design language and a brand language to meet that goal. That was thrilling,” he admits.

A key ingredient in making this a successful venture was to get the right team of people onboard. Jenkins assembled a small but talented team of designers who came with a broad range of experience from different car companies.

Whilst on the engineering side, Rawlinson managed to pull in a number of former colleagues that worked with him in previous roles including on the Tesla Model S.

“As we don’t have a process maturity of a 100 year old company with a heritage of products, individual technical excellence is really a core requirement for all of our engineering team. We rely much more on each other to make sure that the sum total of what we do is effective,” explains Lucid Motors’ director of powertrain David Moseley, who has worked for over 30 years in mostly automotive related engineering in the UK and made the move to California a few years back to work for Lucid.

Lucid – Collaboration is key

To ensure that both designers and engineers are working as efficiently as possible, Rawlinson implemented an office layout where those working in the various disciplines – electromagnetic, thermal, structural, aerodynamic etc. – would be seated together in teams. His view is that this collocation would lead to a collaborative design and engineering process that would not only increase development speed but ultimately improve the end product.

“With engineering and design all in one department, it’s much more of a form and function relationship. Each team member is working with all the other critical team members in a natural and cohesive way so you are solving problems in real time.

“Now, is it always perfectly harmonious? Of course not. But there is a common understanding between the teams of the common goal and that is unlike anything I have experienced in traditional car companies,” says Jenkins.

This collaboration was crucial when refining the car’s architecture and in particular creating a spacious interior space that could accommodate two airline-style rear seats with up to 55 degrees of recline.

“The rear cockpit is meant to look very open, airy and minimal with a lounge-like quality. It was a very challenging part of the design that was about finding the balance of overall cabin space and form fitting these recline seats between the rear wheel arches,” explains Jenkins.

Moseley adds, “That recline was only possible because all those involved – the motor and transmission designers, the inverter designers, the sub frame designers and the Body in White designers – all knew it was perceived as a USP [unique selling point] for the vehicle and worked together to ensure that all the systems were very tightly interlocked to accommodate the deep recline of the rear seats whilst still accommodating the performance of the drive units and suspension system. This required hour-by-hour interaction to achieve in any reasonable timescale.”

Digital design tools

In terms of the design process, Jenkins admits that it’s the most digital car programme he has ever worked on.

From sketching the designers moved quickly into creating concept models in Autodesk Alias. Then with Autodesk’s 3D visualisation tool VRED together with the HTC Vive headsets they could explore many different variants in virtual reality (VR).

“For instance, we had a situation where we were looking at a wheel base change or a vehicle height change and in VR you can move back and forth between these variants to see where the benefits or compromises to the design are.

“We were doing that between the designers and the engineers all at the same time so we both have a common understanding of what those changes would impact. So the virtual really helps to accelerate the decision making in that process,” describes Jenkins.

Not all prototyping was virtual, however, as they did end up validating those changes in a full-size clay model. But the results achieved through using the virtual tools have been very close to what was produced in reality and Jenkins’ view is that they’ll be able to push the clay validation stage much farther down the line, saving even more time in the process.

“Being able to experiment with more variations is a wonderful thing. Lately my team have been tired of me asking every time there is a new colour, material or design to put it into VR before I’ll give them a decision,” he laughs.

“But I do genuinely believe in the tool and the next stage is we’ll move more towards augmented technologies. We are currently looking into how we can bring those tools into the working process as well.”

Understanding the physics

The engineers also rely heavily on digital tools in their simulation-driven design process. With many components being designed in-house and those components interacting with one another in the development of the powertrain, it called for multiphysics analysis. In other words, simultaneous electromagnetic, thermal, mechanical and systems analysis of these components and subsystems of the vehicle.

Although the engineers do rely on multiphyiscs simulation software such as Altair and Ansys, Moseley is quick to point out that these are merely tools and far more crucial is a deep understanding of the physics.

“What Ansys and other software partners have done is provide the tools that enable you to deliver virtual development but you do need the skills required to use them effectively, which is about really burying yourself deeply in the understanding of the physics of the system you’re developing. Without this understanding, analysis can be dangerously misleading.

“We are analysis nuts, but we’re also deeply sceptical of all our analysis. This tension between scepticism and ambition is important in the effective use of simulation,” adds Moseley.

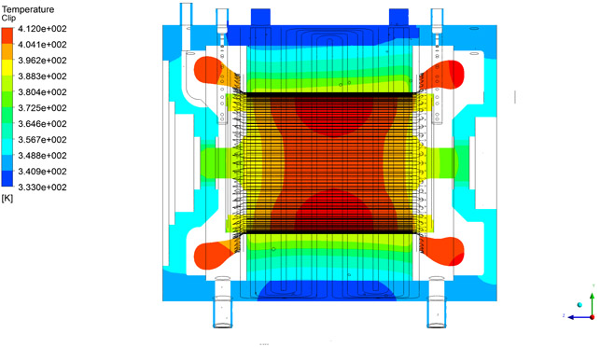

Although there are many examples of where multiphysics simulation has been used (see boxout below), one that Moseley particularly likes is the innovative cooling strategy that has been incorporated into the stators of its motors.

A stator is the stationary part of the electric motor’s electromagnetic circuit. Consisting of windings, it basically provides a rotating magnetic field that guides the flow of energy to or from the rotating component of the system.

“I can’t provide a hugely detailed account yet for confidentiality reasons, but we’ve come up with a strategy that really transforms the cooling of the motors.

“Being an electromagnetic, thermal and mechanical design challenge, Ansys offered a great shared environment to explore that combination of mini physics problems.

So, using these tools together with an understanding of physics, my colleagues created a first prototype that, when put on our dynamotors and tested, entirely fulfilled our analytical expectations.”

Down the road

Meanwhile, the styling team were going through many iterations and refinements of the car to perfect its look. And rather than adding lines and details, they were subtracting as much as possible.

“We distilled the design until we got to something that was very clean, elegant and pure. When I look at the car now, I don’t know what else I would subtract,” says Jenkins.

Towards the end of 2016 the Alpha engineering prototype was reaching completion and following its official launch in December 2016, the Lucid Air was shown at various events and auto shows in 2017 as well as being put through its paces on the track where it set a top speed run of 235mph.

According to Moseley, seeing the car that they’ve worked so hard on for the past two years at these events and how well it was received, makes it all seem worthwhile.

“Of course one’s own baby is always the most beautiful, so there’s a danger that we might be living in a happy bubble of self belief. But when we take our baby out on the road and expose it to public evaluation the reaction is so satisfying and reassuring,” he says.

“It will be an extraordinary experience to drive it, and I am so looking forward to picking up the keys to mine.”

That’s right. Moseley, Jenkins as well as quite a few other Lucid employees have paid $2,500 to reserve a Lucid Air once it’s off the production line.

“I absolutely put a deposit down, it’s a motivation,” laughs Jenkins. “The problem with that is that the employees are always the last to get the car but I’m ok with that. I’d be quite thrilled just to see it on the road and in the public’s hands.”

Of course, before that point, they need to be manufactured and for that a factory site has been acquired in Case Grande, Arizona. Once the finance round has been closed, which is apparently imminent, there will be a pretty intense run up to the start of production, which will start in 2019.

Meanwhile the Lucid team is working away on a number of other vehicles that will be built on the Lucid Air’s adaptable platform as well as on a pipeline of new technologies for the powertrain. As Moseley puts it, “With the Lucid Air we are just removing the topsoil from a mine of innovation still to come. Stay tuned!”

David Moseley, Lucid Motor’s head of powertrain, will be giving a keynote talk entitled ‘The role of multiphysics simulation in the development of the all-electric Lucid Air’ at DEVELOP3D LIVE on Wednesday 20 March at Warwick Arts Centre.

Multiphysics simulation

During the development of the Lucid Air, the engineering team made extensive use of multiphysics simulation software, which enables simultaneous optimisation of all the different subsystems of the vehicle.

One example where it was used extensively was in the development of the motor.

With Ansys Maxwell — an electromagnetic field simulation software — the engineers could conduct analysis of electric motors, actuators, sensors,

transformers, and other electromagnetic and electromechanical devices.

Maxwell determined electromagnetic losses in the motor and, through ANSYS Workbench — the host environment and data exchange backbone of the Ansys simulation platform — integrated these losses with an Ansys Fluent simulation to determine temperatures throughout the motor.

Two separate systems cool the motor. The first is a water jacket moulded into the motor case. In the second system, transmission oil is injected into the hottest areas — the end windings and rotor. Engineers used two coupled models, an oil model and a water model, to simulate these two cooling systems.

Multiphase transient analysis with the volume of fluids model was used to solve the domain cooled by oil in the oil model.

This model produced heat transfer coefficients of the surface wetted by the oil and the local oil temperatures. Engineers modelled the water cooling system with a water model in Fluent that used steady-state conjugate heat transfer to predict temperatures of the solid components of the motor.

The temperatures predicted by the water model were then used with the oil model and the simulation was run again.

The resulting heat transfer values were mapped to the water model.

This iterative process continued until the two models converged on the same temperatures.

After the models converged, Workbench enabled the engineers to easily incorporate the temperatures of the solid objects into an Ansys Mechanical structural model to calculate thermal stresses and, finally, to perform fatigue analysis to ensure that the motor will deliver its promised life.

Using simulation, Lucid engineers increased the power density and energy efficiency of the motor by 12 per cent. The temperature predictions matched physical measurements within a 3 per cent margin of error.