Microfluidics is opening new doors for research scientists. DEVELOP3D spoke to the team at IotaSciences, a start-up that has used iterative prototyping to bring to life a new, ground-breaking approach to this process

Microfluidics is one of the fastest moving areas of scientific research. As its name suggests, it focuses on the control and manipulation of fluids at very small scale, enabling scientists to perform molecular analysis, right down to single-cell levels. That’s valuable for single-cell cloning, for example, used in fields such as stem cell research, genome editing and drug development.

But providing researchers with easy access to cells depends on confining tiny volumes of fluid to optically clear chambers – and building a good microfluidic environment is a complex endeavour in itself. That can often make the devices that provide this kind of environment expensive and acquiring them often involves long lead times.

IotaSciences, an Oxford University spin-out company, is on a mission to solve the problem, and to make fabrication of microfluidic devices an in-house, low-cost and rapid process, comparable to 3D printing.

Founded in 2016, the company builds instruments that use a proprietary technology to build what it calls ‘fluid walls’. Perhaps the easiest way to explain this is to imagine holding a glass of water, where the glass is made from immiscible fluorocarbon oil.

IotaSciences’ technology is used to create both static structures and flowing circuits. In the latter, Laplace pressure is used to create a pump with no moving parts, with the pump itself a liquid.

With this technology, IotaSciences’ devices can be used to create simple micro wells with fluid walls containing less than one microliter of fluid. To do so, a thin film of cell media (or stem-cell coatings) is reshaped using a microjet to create a grid of 256 chambers on a 60mm dish. This is currently used to isolate a single cell in the lab for downstream experiments.

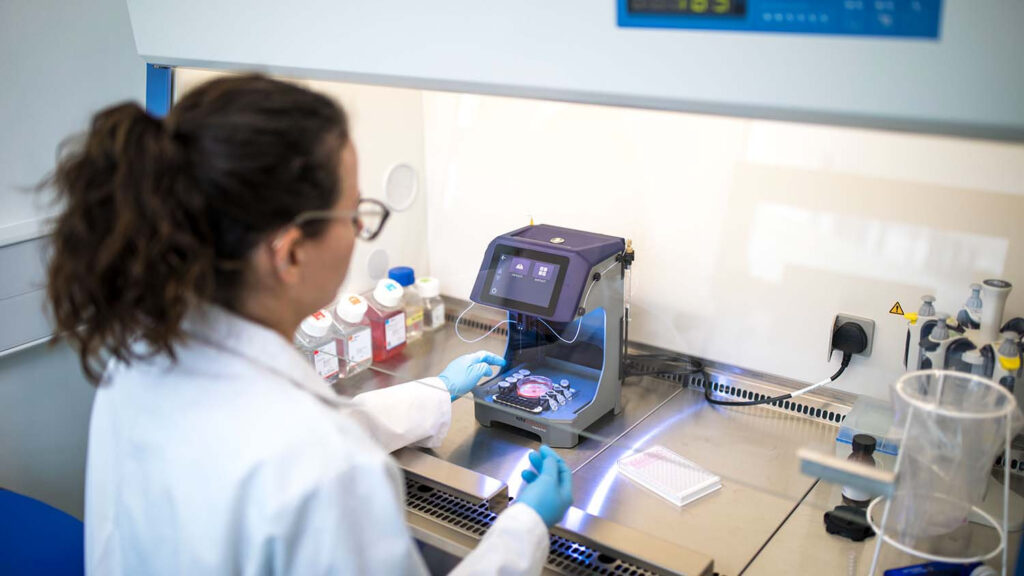

To make this work even more ground-breaking, IotaSciences has housed the technology in its IsoCell device, an easily transportable, 3.5kg system that is comparatively tiny compared to others of its kind.

Iterative prototypes

The concept was first stumbled upon when Professor Ed Walsh of the Oxford University Department of Engineering Science was looking to help Professor Peter Cook and Dr Feuerborn at the Oxford Dunn School of Pathology, who were collaborating on an unrelated technology to solve microfluidic problems encountered in microbiology research.

From the initial idea, the development moved at pace based on iterative prototyping, with corporate and private investors backing the start-up.

Sketches were mostly drawn on glass partition office walls to aid collaboration between engineers, while an adapted 3D printer was repurposed as an evolving prototype.

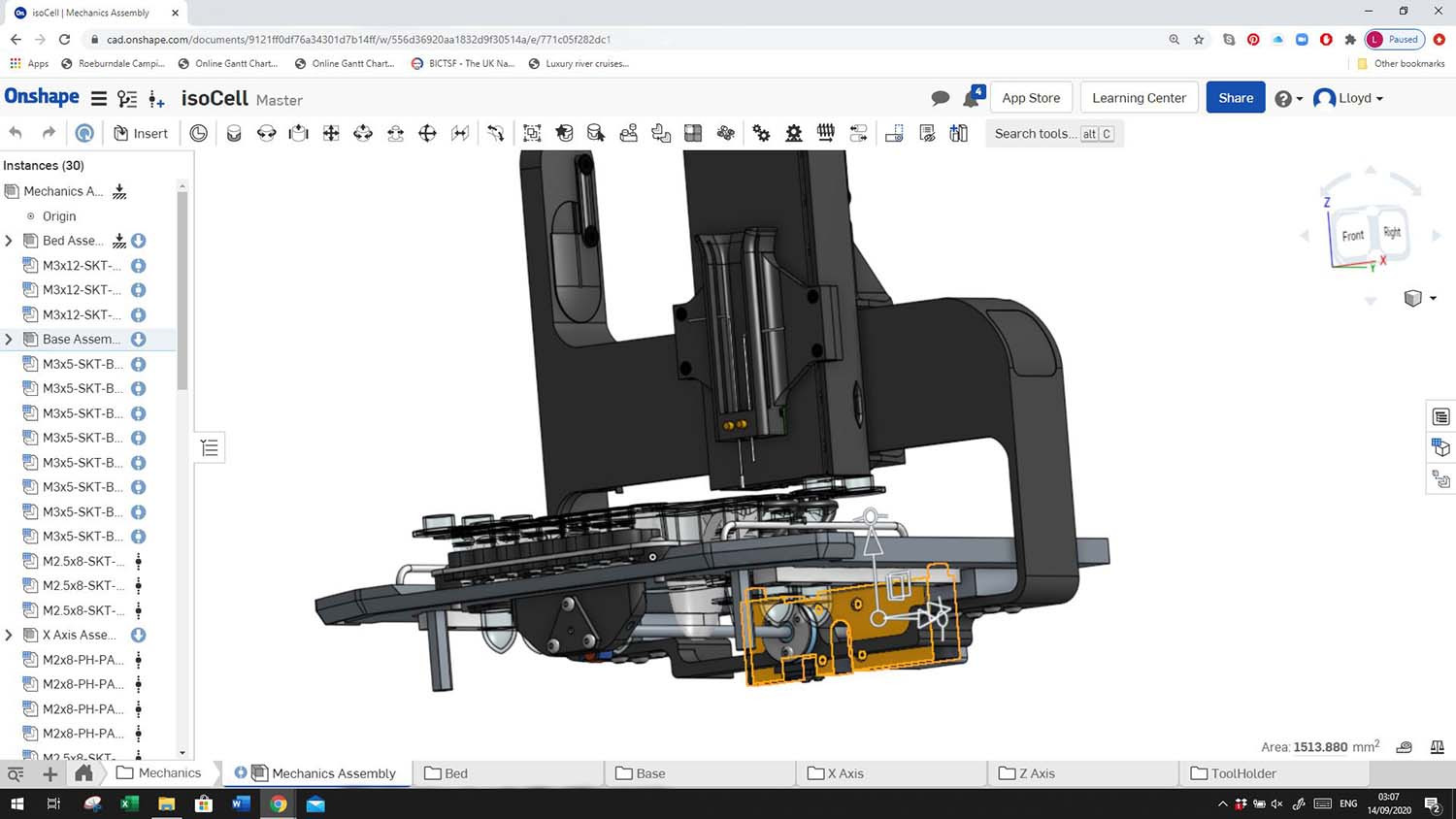

Onshape was chosen from the outset as the preferred 3D CAD tool over Solidworks, despite the design team’s previous experiences with the latter. That was down to Onshape’s low cost of adoption, built-in version control and collaboration tools, according to the team.

Printing the fluid walls presented an early challenge for the project. Initially, a stylus was used to ‘draw’ and shape the fluids. The problem was overcome by shifting away from this contact stylus-based process, to a non-contact microjetting process instead.

In the latter part of 2018, the design team built a small number of the IsoCell systems instrument as field prototypes.

Here, digital manufacturing was adopted, using machined aluminium components from ProtoLabs and 3D-printed polymer parts from bureaux 3DPrintUK and Malcolm Nichols. The systems were then assembled inhouse, by hand.

Following successful trials, a pre-production prototype was developed, with design for mass manufacture introduced with the help of Norwich-based design consultancy, Product Resolutions.

In the later stages of development, issues relating to vibration and noise needed to be tackled. The design team solved this without simulation software, instead choosing to work from the ground up with calculations done by hand, based on how the physical prototypes were behaving under a given situation, and using Onshape to input all design changes.

As a result of the proprietary IotaSciences technology, the IsoCell is considered to be gentler on cells, uses fewer reagents, adds automation to the cloning task and provides unmatched optical clarity for single-cell identification, therefore lowering the cost of experiments while improving the quality of results.

The system boasts significantly better optical performance under a laboratory microscope, due to the small size and nature of the wells with fluid walls, while its user interface makes it simple to use for the operator.

The simplicity and user-centred design built into the IsoCell has meant IotaSciences has successfully completed remote installations and training during the Covid-19 pandemic, with the device now ready to be put to use on helping to research a future Covid-19 vaccine.