Deliver-E is a technology demonstrator for a new type of electric delivery vehicle that has been created by teams at WMG and Astheimer

The automotive landscape is changing. In the future we’ll be getting around in electric vehicles, of that there is little doubt. And with strides being made in autonomous technology, many of these vehicles could also be driverless.

“Electric and autonomous vehicles are areas that are experiencing a lot of growth and change and at Astheimer we are positioning ourselves as experts in both those areas,” says founder and creative director Carsten Astheimer of the eponymously named Warwick-based design consultancy.

And if there is one thing that Carsten Astheimer knows about, it’s designing cars, as well as other modes of transport. Having completed his degree in mechanical engineering from the University of Leicester, he crossed the pond to California where he spent the next four years studying transportation design at ArtCenter College of Design.

Following a year of working at the Volkswagen design studio in Simi Valley where he met some inspirational car designers he moved to Turin in Italy to work for the country’s famed automotive design house Pininfarina.

After a few years he moved to its industrial design studio, Pininfarina Extra, where he was appointed design manager. With ten years of high-end automotive and product design experience under his belt, Astheimer decided that his future lay in marine design. He was on track to work in the US taking up the role of the global design director of the Brunswick Group, the largest maker of pleasure boats in the world, but following a two year stint at its subsidiary in Kidderminster, UK, the 2008 credit crunch put a halt to those plans.

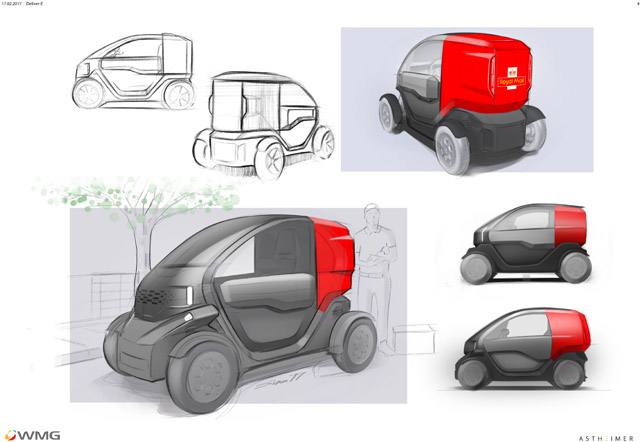

The design process started with sketching out ideas

Looking for his next move, and finding himself in the Midlands with a young family of four kids, he decided to set up his own consultancy. Following his first project – the Sealine F42 flybridge cruiser, which went on to win the 2011 Motor Boat of the Year Award – he hasn’t looked back.

With an expanded team of ten designers (soon to be eleven), Astheimer works across a range of sectors on a mix of projects.

As an example of this variety, on the day I visited there was one designer working on a design for an articulated truck, another on a motorhome, another on some agricultural equipment and then another on chocolate bars.

Although you may not think it, the latter is a pretty involved piece of design work. For the past five years Astheimer has designed and engineered moulded chocolate bars for Mars, in particular for its Galaxy brand.

“The chocolate bar, which is quite a complex shape, needs to have exactly the right amount of volume and weight. It needs to have very precise mould release angles, and to break properly but not break in transport,” he explains.

Of course, this would call for testing during the design process especially ‘in mouth’ experience testing. “I used to eat a huge amount of chocolate and now I don’t eat any,” laughs Astheimer.

Autodesk VRED VR being used to visualise the 3D data

The designers have all the latest tools available for each stage of the design process from the latest hardware and software through to a fully equipped workshop and, more recently, a permanent virtual reality set-up (see box out below).

“We use VR all the time in our projects. It is especially good for understanding scale. Our work takes us from a mobile phone to a 55m super yacht and everything in between and on the screen they’re all the same size, so understanding scale and ergonomics is really important,” describes Astheimer.

Although the consultancy works across a variety of projects, which Astheimer claims keeps them abreast of industry trends and helps to cross-pollinate ideas, it sees itself as a boutique, high-end external design studio for the automotive and transportation sectors.

And it works with a range of leaders in these sectors. The likes of Bentley, Rolls Royce, Jaguar Land Rover, Ferrari, Prodrive and Williams on all manner of interesting solutions around electric and autonomous technologies. But something that no doubt other design consultancies can frustratingly relate to in their work, these projects are very exciting but also very secret.

However, an electric vehicle project Astheimer can share is the Deliver-E prototype, which was designed and developed in collaboration with the Warwick Manufacturing Group (WMG) based at the University of Warwick.

In the latter stages of the development process and the demonstrator is in Astheimer’s workshop with the lights being programmed

Brief from WMG

Having collaborated with Astheimer for the past five years on numerous other projects, WMG approached the consultancy with the brief of showcasing its new battery technologies and control systems in a real-life demonstrator vehicle.

“In our initial discussions we thought that this prototype should be a delivery vehicle. There has been a huge increase in buying online and most inner cities are already congested and way above their quota for carbon emissions.

“A small electric delivery vehicle will become more relevant whether it is Dominos Pizza, Sainsbury’s or the Royal Mail,” comments Astheimer.

A rendering showing commercial livery and the access to the cargo space

With the brief in hand the crux was that WMG wanted the demonstrator vehicle delivered in ten short weeks. As Astheimer says, it was pretty much a case of each designer dropping what they were doing to get all hands on deck.

With Renault having released its battery-powered two seater electric city car, Twizy, as an open-source platform, the design team decided to use that as the donor vehicle.

“We took off the body panels and 3D scanned the vehicle using a Shining 3D EinScan-Pro laser scanner. We determined first of all what cargo space we could fit into it whilst retaining the structural integrity of the frame.

We established that we could create a total of 300 litres and fit in at least three of those trays that supermarket delivery vans use,” says Astheimer.

The process of creating a new identity for the vehicle began with sketching. Astheimer stresses that sketching is one of the most vital tools of the design team.

“Sketching is the designer’s language. The ability to sketch enables you to visualise a product in three dimensions and if you can’t do that you are going to be limited,” he admits.

The look the team came up with for the Deliver-E is described by Astheimer as being modern, purposefulbut simple. The top part being graphically different to the bottom helps convey the message that it’s a commercial rather than a consumer vehicle.

Astheimer designs and engineers the moulds for the Mars Group, particularly its Galaxy chocolate bars

The team then moved into its CAD tool Rhino and converted the point cloud data from the scanner into a 3D model. In total eight full CAD models of the car were created, including design changes, build strategy updates and feasibility feedback loops from suppliers.

In this project, the team also made use of a plug-in for Rhino called Grasshopper. Predominantly used in the architectural field, this visual programming language builds generative algorithms, which when applied to a surface creates 3D fading patterns and meshes. In the case of this project, it was used to create the pattern on the front and rear ‘grills’.

“It is actually a service we offer to a number of OEMs including Bentley in order to generate the intricate parametric surfacing it requires for its cars.

“It is a fascinating piece of software. What is interesting is that once you have created the algorithm you can create these sliders or graphs within it. When you move the slider, you then change the intensity of the pattern, its depth, its amplitude, how quickly it fades or not. So you can control it very well,” explains Astheimer.

The Sealine F42 flybridge cruiser was the first project awarded to Astheimer

Astheimer – Using VR in the process

With the CAD complete, the team used its VR set-up to check the assembly of the parts. It also meant that instead of having time consuming prototypes made, the WMG team could instead come round to their studio to don the HTC Vive headset and scrutinise a life-size photorealistic digital prototype created using Autodesk VRED.

“In week one we had determined the package and started sketching. In week two we had decided on the design direction, in week three we had a full CAS [computer added styling] model of the car and by week four we had defined the external A surfaces including Grasshopper, the lights and the requirements for the packaging of the main components as well as the door opening and the cargo space. In weeks five and six we developed all the B surfaces including all assembly and fixing details.

“This meant that of the ten week project, the design side of things took about six weeks. It was an intense time,” smiles Astheimer.

The new Newmar 2017 King Air Luxury Motor Coach

All the body panel parts were then created by directly milling ABS blocks, which was another two week process.

When the finished parts were delivered, it was time to assemble the car and incorporate WMG’s 48-volt 6.5kWh battery system.

“During the course of several dry fittings, components were refined and new electronics installed, including programming an Arduino for a fully animated lighting system.

“The mounting of the front grill completed the vehicle’s character and marked the end of the 10 week project,” says Astheimer.

The Deliver-E had its first outing in Warwick University grounds in September 2017. It has since been showcased as a demonstrator at a number of events and will also be used by WMG and its partners when undertaking research around electric vehicles.

For the Deliver-E prototype, the design team created 3D fading patterns for the vehicle’s grill using Grasshopper

“I think what I am most pleased about with this project is that it is a very coherent design. It has a unique appearance and it retains our studio design philosophy of ‘Perfection is attained not when there is nothing more to add, but when there is nothing left to take away’.

“It’s a quote from the French writer Antoine de Saint- Exupery who wrote the book The Little Prince, a man much cleverer than me,” laughs Astheimer. With the journey Astheimer has been on and the direction he is steering his company in, that’s a moot point.

How Astheimer has adopted virtual reality in its product design workflow

About a year ago, Astheimer decided to bite the bullet and invest in a virtual reality (VR) set-up. It admittedly wasn’t cheap but CEO Carsten Astheimer felt it was worth the investment not only for presentation purposes with clients but also for use during the product development process.

He approached Autodesk reseller Majenta Solutions, which then equipped the consultancy with VRED Presenter rendering software and a HTC Vive headset.

The first noticeable advantage to using VR was the ability to understand scale.

“For example, we’re designing a truck and some agricultural equipment at the moment which are big, as they tend to be. But on the computer screen it would be the same size as a mobile phone. So using VR to understand proportion as well as ergonomics has proven very useful,” explains Astheimer.

“Then, of course, it’s been great for presentations as it gives clients a completely different experience when they can walk around a life-size virtual prototype.”

Virtual prototypes also negate the need for expensive prototypes to be made. This reduces project times and translates as substantial cost savings not only to the consultancy but to the client too.

“At the start of a recent truck cab project, I laid out two routes for the client. In the VR route we’d make simple dimensionally accurate mock-ups in CNC plywood for the ergonomics, because one thing you don’t get in VR is being able to step up into something. But then they’d get the full visual of VR with the mock-ups so sight lines and they’d also be able to click onto different variants. This route would be used all the way through to the final pre-production prototype,” explains Astheimer.

“The traditional route, which would involve a full-scale model of a truck cab, would have cost £20,000 more. The client went for the VR route and has been really happy so far.”

And although Astheimer argues that this reduction in costs for a project does give them a competitive advantage over other design consultancies, he strongly believes it will help deliver a better project at the end of the process too.

Despite all these advantages, a big draw to getting onboard with VR is simply because it’s the future and it’s where technology is heading. “I do think we will start to design in 3D. It will be a matter of time but it is where we will end up so it’s best to get people trained on it now.

“If we can start modelling in VR and 3D it will allow us to design on our feet, interacting with each other and away from a screen. We can shape the design with our hands, not by using a mouse; it will become an engaging activity, which is just how product design used to be, before we sat in front of computers 24/7,” claims Astheimer.

His advice to other design and engineering firms who may be considering whether to dip their toes in VR, is to try it first to discover whether it will fit in with their workflow, improve processes and, if indeed, have any impact on the business. “From my point of view, it is now an invaluable tool in our toolkit,” he concludes.