Following the success of the Kano Computer Kit in 2014, we talk to the design team behind the development of Kano’s three new coding kits that aim to get children (including grown-up children) playing with and hacking technology

Screen time: it’s a term with which most parents are all too familiar, as they struggle to limit the amount of time their children spend sitting in front of screens. But what if screen time was less about passive consuming and more about getting under behind the screen, in order to build and experiment with the technology beneath?

One company on a mission to do just that is London tech start-up Kano Computing. Its Kano Computer Kit was revealed in 2013 and, following a hugely successful Kickstarter campaign that secured $1.5 million in funding, taken into mass manufacture for its 2014 launch. Backers of the campaign famously included Steve Wozniak, cofounder of Apple, and Yancey Strickler, co-founder and CEO of Kickstarter.

The Kano Computer Kit is essentially a DIY computer that users build and code themselves. It includes Kano’s signature orange keyboard with inbuilt trackpad and a Raspberry Pi ‘brain’.

Following a story-based instruction guide, included in the packaging, users assemble their computer by simply snapping together components. They can then start coding through easy-to-follow steps and, before they know it, they are hacking Minecraft worlds, making visual art and creating games. Between them, users of the computer kit, predominantly aimed at children between the ages of 8 and 14, have to date written over 51 million lines of code.

“A lot of kids don’t necessarily have the experience of seeing inside a computer. [They don’t know] what a processor is or even how a USB connects up and how speakers are driven through the computer. Demystifying these things was the main appeal for us in creating the kit,” explains Bruno Schillinger, lead product designer at Kano.

Kano – moving forwards

Since launch, Kano has gone on to launch the Screen Kit, Laptop Kit, an updated Computer Kit and is now moving into consumer electronics. Earlier this year at the Consumer Electronics Show (CES) in Las Vegas, it showcased the latest working prototype of its Camera Kit.

Far from being a mere point-and-click camera with a preselected choice of filters, with this DIY coding kit, users first build their 5-megapixel camera and then begin to code their own filters and colourful flashes, among other tasks.

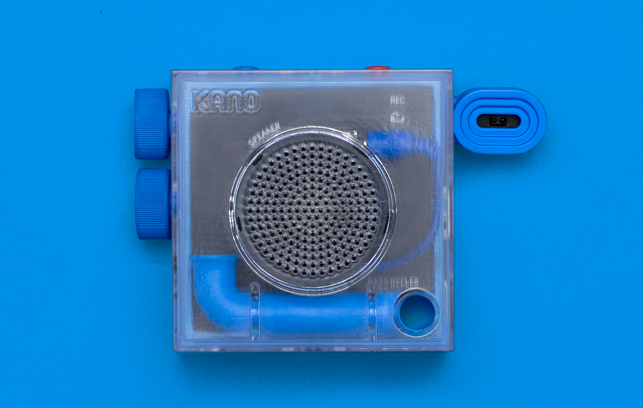

As well as the Camera Kit, two other coding kits were developed at the same time: a Pixel Kit, which is a smart interactive board made up of 128 LEDS; and a Speaker Kit, which can record and play back music and sound effects.

These kits were designed in collaboration with London based industrial design consultancy Map, which has worked with Kano from the start. With its first Computer Kit, Kano’s co-founder Alex Klein approached Map with a box of off-the-shelf components and asked the design team to help create a computer building experience that was intuitive and cohesive.

“That is how my journey with Kano began. I was working at Map as an intern at the time and one of my projects was for Kano, designing the initial packaging and the approach to form design,” describes Schillinger.

Kano – new ideas

At the start of this project, Map hosted a two-day workshop at its offices to help the teams identify these potential new coding kits. “For it to be a Kano product, we had three criteria,” explains Jon Marshall, principal of Map.

“Firstly, it had to be a recognisable, everyday object; secondly, it had to be something that you could build yourself from a kit through a number of build steps; and thirdly, you had to be able to code it directly using a Kano Computer Kit or on a normal computer.

He adds: “We wanted to make kids feel empowered, by providing them with an understanding of the code that drives these products. So, for instance, with the Camera Kit, the software takes you step by step through how you can take an image, how you can create a self-timer for a camera and then you can use code to manipulate the image.”

With the three kits identified, it was time to set about designing them. Again, this is a very collaborative process between Kano and Map. Sometimes the designers even work for periods in each others’ offices.

The challenge was to ensure that design language and cues from the original Computer Kit were carried through into the new products. “In a way, we were implementing the design language we had already established, such as the use of transparent plastic, because it’s about showing the tech for what it is and allowing people to see how things work,” describes Marshall.

During the design process, the designers progressed from quick sketches and 2D drawings in Illustrator to creating rough-and-ready card and foam models to get a handle on size and dimensions. SolidWorks is used to create the CAD models and then high- quality renders done in Keyshot to check material, the finishes and smaller ergonomic details, such as buttons and controls.

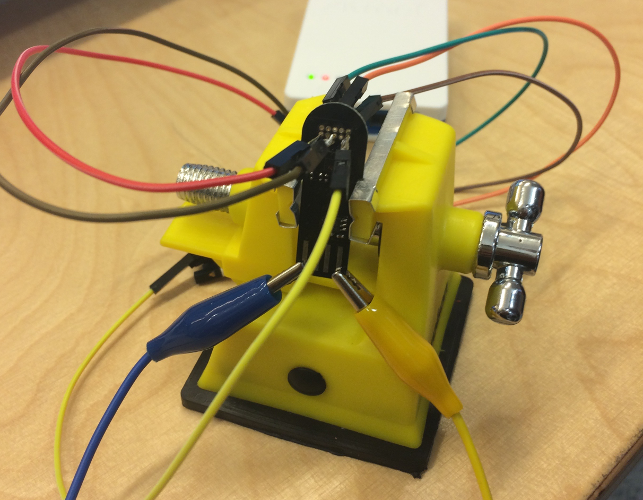

As a design progresses through the development process, prototypes are continually created, some still in foam and card, but others using Map’s in-house FormLabs 3D printer.

“For every physical model, we are also working in CAD to make sure that things are dimensionally correct. The designers often work simultaneously with physical models and with the CAD model and use both to influence each other. That’s a process that works very well for us,” Marshall reports.

Of course, while design is important, a lot of the experience with these devices happens digitally. For these kits, Kano not only built its own chips and circuit boards, but also its own visual coding editor called Kano Code.

“Kano Code is a really versatile block-spaced coding interface, similar to other programmes that are really popular with kids, like Scratch or Hopscotch. The difference with ours is you can fix the hardware up to it.

So with a push of a button you can, for instance, add your Camera Kit into the creation and then start hooking it up to other variables using this coding interface,” explains Schillinger.

“Creating this software and managing all of the different permutations of projects that you can make using all of our different hardware products was a huge challenge.

That is what we did in-house with our software design and development teams, which is of course very closely integrated with the hardware design as well,” he adds.

Sense and respond

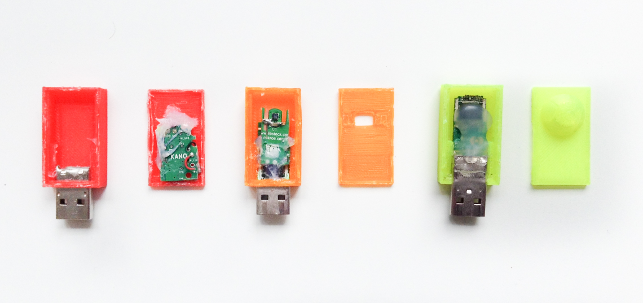

As the design of these new kits progressed, the design team started to explore the idea of creating optional, standalone USB sensors, which could either be plugged into these kits or, indeed, any USB-compatible device in order to provide additional functionality.

“We often debated this idea of modularity, where you can add really interesting new experiences and different functions, but in very simple and inexpensive way. The idea for creating sensors came out of that,” says Schillinger.

“We really like sensor technology, because once you learn about programming and how to control electronics within products, sensors become a really important part of how you interact with the digital world.”

Five sensors were created. First, there’s the Tilt sensor, which contains a gyroscope and accelerometer to measure movement and speed. The Sound sensor, meanwhile, is a microphone, while the Tripwire sensor is triggered by movement over a 7-metre distance. The Air sensor reads temperature and humidity, and finally, the Gesture sensor reads the distance to whatever is in front of it and recognises hand gestures.

The casings for these sensors presented an interesting design challenge. With no point of reference, since sensors aren’t usually pulled out of devices and given a form, the team looked to how sensors work for inspiration.

As Schillinger explains: “So we looked at technological objects that fulfilled similar functions, but weren’t obviously electronic sensor chips. For example, with the Tilt sensor, which measures your movement at different axes, we were looking at marble runs and balance. And for the Tripwire sensor, we designed it to resemble an eye, keeping a lookout for anything that crosses its path.”

Designed in SolidWorks, Kano made extensive use of its in-house 3D printers during the development of these sensors. In fact, it upgraded its machines for this project.

“We had a couple of standard 3D printers like Makerbot and Flashforge printers, but with the sensors being such small objects, we needed higher resolution prints in order to test them properly. So we’ve moved to Formlabs printers and have a couple of Form 2’s, which are SLA-resin printers that give a really nice resolution,” says Schillinger.

Customer approval

A crucial part of the design and development process for all Kano’s products is testing their usability with children.

In fact, one of Kano’s design philosophies is that everything should be sufficiently usable for a six-year-old to be able to perform a task without adult supervision or help. If it passes that test, then the team know it’s successfully designed a Kano build process.

“We involve kids at all stages, from early prototypes through to testing actual plastics that come off the tools.

Kids are great for product testing, because they are the most honest sounding board you can possibly have. They don’t mind telling you if something is boring or if it’s not fun,” laughs Schillinger.

When testing the camera kit prototype, they found that what really resonated with kids was the idea that they could hack up what they perceive photo technology to be, so that it feels like something they have real control over.

”We had them take photos using the camera kit and then tweak loads of parameters in the code for the photos, so that it ended up being this weird, distorted pixelised image. They really enjoyed that,” he says.

“We also tested them plugging the different sensors into the camera. For example, we had a kid plug in the Tripwire sensor and then set up the camera in their garden so when a fox ran in front of it, it triggered it to take pictures.

Those new experiences of tech, which aren’t new but are presented to them in a new way, we found was really exciting for them.”

Kano – looking ahead

With the prototypes of the three new kits in a good state, Kano decided to launch a Kickstarter campaign at the end of 2016, which raised over $640,000 in funding. However, of the three kits, only the Pixel Kit has so far been shipped to backers. The Speaker and Camera Kits are scheduled to ship at the beginning of 2019.

“Obviously, we want to ensure that we’re providing an experience that is as good as possible. What we have done over the course of the past year is change some of the fundamental hardware underneath the camera to make it run better and we’ve also created the Kano App, which controls the coding kits, but there are challenges that go with it too,” says Schillinger. But, he adds, “We do work through all these challenges and, as we’re developing as an organisation and building a larger in-house team, our processes are becoming more streamlined.”

Kano is maturing – but thankfully for young customers, its child-like love of exploration seems as fresh as ever.