Audiophiles are forever harking back to a time of warm, smooth bass tones and clear top notes, and will usually spend top dollar in pursuing it from today’s modern hi-fi equipment.

The HDX component hard drive: 500Gb of bit-perfect, CD quality sound storage, is designed by Naim, a high-end audio equipment firm that does a fine line in serious audio systems that cost roughly the same as a nice car (incidentally, on the side, Naim also fit out nice Bentleys with audio systems).

Luxury sound quality at it’s coolest

Although clothed in a rather charmless-looking black box, the HDX is trying to help with the mammoth task of motivating thousands of middle-aged men into giving up their giant vinyl and CD collections and transferring their beloved LPs into MP3s, without harming the sound quality.

It’s no looker, but on the inside it is a marvel of design and electronic engineering in a business where the quality of the sound counts.

Sold worldwide, in a variety of climates (I’m guessing mansions in tropical paradises) keeping the hard-drive at a relatively constant temperature was the main challenge for the team of 30 designers at Naim’s headquarters in Salisbury.

“We had to be very conscious of the temperature inside the unit,” says Paul Neville, Naim’s audio mechanical design manager. “Hard drives have a temperature they like to turn at, and it reduces their life expectancy if they run too hot. The bearings wear out, for example.

“The HDX was our first product with a hard drive, and it also has significantly more software than anything else we’ve designed. A complex product means more electronics, and more electronics generate more heat. At the same time, they reduce the amount of room in the unit that allows heat to circulate through.”

As a result, thermal analysis was key to the design.

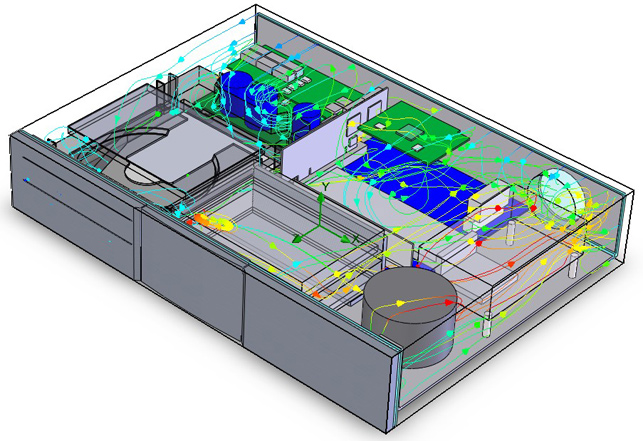

Naim used SolidWorks Flow Simulation, taking a CAD model of the HDX as a starting point to create a thermal analysis. The model enabled them to predict the flow patterns and maximum temperatures inside the HDX.

Designers modified the CAD models in response to the thermal analysis, then ran another analysis to ensure the modification would work.

Using SolidWorks Flow Simulation Naim saved the time and cost of building ten physical prototypes

It also worked well for giving comparative solutions. “If we changed the material or thickness of a heat sink, we would run another analysis to see what effect that had on key components,” explains Paul. “Otherwise, we would have had to use physical prototypes, and that would have taken a lot of time.”

By testing 10 different scenarios in the CAD model the HDX design needed only two physical prototypes to verify the thermal results. As Paul points out: “If not for the software, we would have needed 10 prototypes.”

Using the results as a guide, Naim settled on a design that includes a 5mm thick aluminum product case that provides a built-in heat sink for the components and a path to remove heat from product. Components were mounted to the case so their heat would radiate out of the product.

Designers moved the primary hard drive close to the cover to shorten the path heat had to travel to get outside, and the internal air flow keeps the fan off unless the temperature rises above 25C.

Here at DEVELOP3D we’ll be ordering one for when we open our new offices in Mauritius.

www.naimaudio.com

This new hard-disc drive is hot stuff, but manages to keep its electrics cool