The all-new Norton V4 super bike with parts that are 80 per cent UK sourced or made in-house

Norton Motorcycles has come a long way since DEVELOP3D last visited over six years ago when we reported on a revered British marque that had been brought back from the brink.

UK businessman Stuart Garner was now at the helm and his small team were operating out of a windswept industrial unit on the side of Donington Park race track.

This time we were confronted with a very different operation. Gone is the ‘metal shed’ and instead the company has moved into nearby Hasting’s House, a stone’s throw from Donington Hall itself, which now also belongs to Norton along with 26 acres within the Donington Park complex.

This 45,000 sq ft facility is home to 130 people including those who work in the design offices, production facilities as well as the 30 apprentices in the British Motorcycling Manufacturing Academy (BMMA), which Norton founded in 2015 to train 16-19 year olds in motorcycle manufacture and supply.

Inside the factory, the staff are working on the build of two brand new V4 1200cc 200bhp sports bikes – the £44,000 Norton V4 SS and the £28,000 Norton V4 RR.

Launched at the UK’s largest bike show – Motorcycle Live – in November 2016, the bikes caused many motorcycle fans to stop in their tracks and, in some cases, empty their wallets because all 200 of the SS version sold out within days and soon after the 250 RR versions had all been sold too.

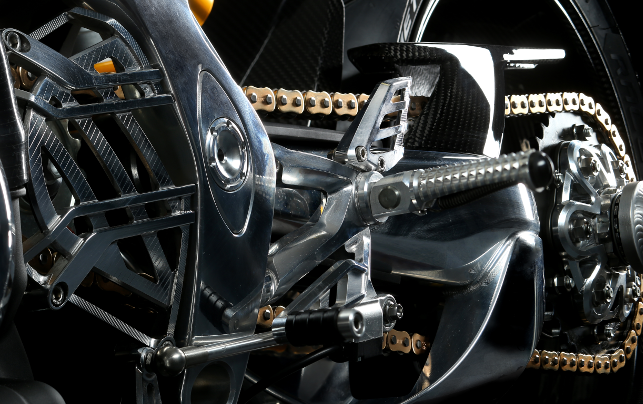

The Norton V4 features full carbon fibre bodywork, available in either bare carbon fibre (RR) or chrome — to replicate the TT race bike — with an airbrushed Union Jack on the tail unit (SS)

Super bike aspiration

The first employee Garner took on back in February 2009 is Norton’s head of design Simon Skinner, who was lured away from his position at Triumph to have full control over design and engineering at Norton.

From the early days, both he and Garner shared a vision of launching an authentic British built super bike. But this vision had to be placed on the back burner while they put the three prototype bikes the company had inherited from its previous owner into production and focused on growing a sustainable business with a brand known for its design, quality of materials, handling and UK manufacture. “We are a premium motorcycle brand so in the marketplace we sit above Triumph and Ducati. Think of Norton as a two-wheeled Aston Martin,” describes Skinner.

In 2012 Norton decided to return to the Isle of Man TT where it had won 94 times in the past and use this 37.73 mile course as a development tool to accumulate information about building modern V4 sports bikes. “On some parts of the course, both the bike’s wheels will be off the ground and we have to design the bike to enable it to do that.

This means that I have to do a lot of FEA work and a lot of structural analysis in PTC Creo to make sure that it can do that lap after lap. So, the engineering has to be very robust on the bike,” says Skinner.

This has resulted in a bike that can handle very well and last year Norton was placed seventh and achieved a lap time of 130.87mph, which crowns it as the fastest British motorcycle to ever lap the TT.

In 2015, Norton was eventually able to apply the engineering learnt from its TT race bike to a road bike when it received £4 million in funding from the government as part of the Advanced Manufacturing Supply Chain Initiative (AMSCI). This would create jobs directly within the company, including apprentices at the BMMA, which Norton set up as a result, as well as indirectly within its supply chain.

The fund would also enable Norton to build and help kit out a new manufacturing plant next to Hasting’s House for fabrication, CNC machining and welding.

//giphy.com/embed/sDPZbjIJM5Sa4

PTC’s freeform modelling and surface creation tool Freestyle was the fundamental reason why Norton could complete the super bike within 12 months

Clean sheet design

So the pressure was now on Skinner to design the Norton V4 and he makes it very clear that it would not merely be a replica of the 2015 TT bike.

“The TT bikes were a development tool and this wouldn’t be the TT bike with lights bolted on – it’s a clean sheet design,” he stresses.

“It would be an all-new Norton and I had to ask myself so many times what that would be – if Norton had carried on building super bikes from its Commando 850 days what would we be building now? That’s what I had to design.”

Staring at his clean sheet of paper in November 2015 he wondered how they would achieve this in the timescale – the goal was to launch the production bike at Motorcycle Live exactly one year later. Skinner did have the idea to go straight from the CAD screen to production tooling.

In other words, no prototyping or clay model stage. But he needed to get the A class surfacing done fi rst and this can take anywhere from 18 months to two years – time he didn’t have.

“When I started the design process, I was looking at bespoke surfacing packages – some PTC, some ICEM Surf and some Rhino. I thought I’d have to get a team of people to create the highly stylised surfaces required and then the guys at Root Solutions [a Cambridge-based supplier of PTC solutions] demonstrated the Freestyle app within Creo and it changed my life, quite frankly,” admits Skinner.

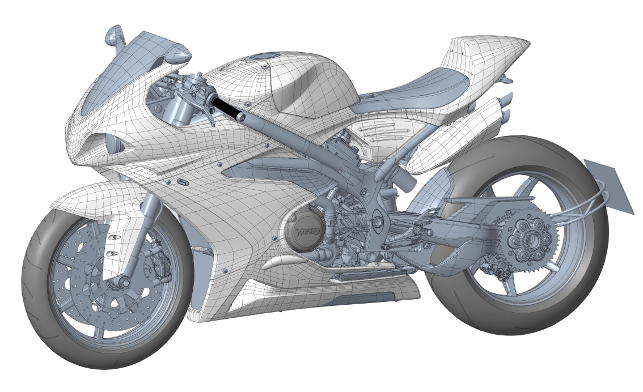

Freestyle is a freeform modelling and surface creation tool within Creo Parametric that has been specifi cally created to deal with complex surfaces and can automatically create curvature continuous manufacturable surfaces easily and intuitively.

Based on sub-divisional technology, the user starts with a primitive shape and then uses a 3D dragger to push and pull it, much like a designer would physically shape their design in the traditional clay modelling stage. The resulting geometry has high quality curvature continuous surfaces that can be used within Creo, as well as downstream.

The whole design and development process from FEA, surfacing, modelling and rendering was done within Creo

“I simply wouldn’t have been able to do the bike without it. Conventional surfacing packages, conventional ways of modelling, conventional design processes and design techniques would not get the bike to the NEC in 12 months. So it has completely revolutionised what I am doing here. I can’t overstate that enough. It was like an epiphany – where has it been all my life?”

With Freestyle, Skinner could surface the whole bike with all the basic fundamental surfaces complete within a month. “It is a massively powerful tool that is so quick and easy to use. Once done I gave all that raw data to my engineers and they turned it into bodywork with tabs, thicknesses and refined the surfaces in Creo where need be,” he explains.

Another advantage of Freestyle is that it’s within the Creo suite of tools, which meant that Skinner didn’t have to switch between tools, helping further accelerate the design process.

“I like using Creo because I can create a moveable geometry part, which means I can move the bike around and change position of various bits depending where I want them to be, I can do FEA and now I can do the surfacing. It is a one-stop shop and I haven’t got to jump from one system to another to another depending on what I am doing. So, it’s nice and easy for me from a user’s point of view – I can just get on and go,” he comments.

The Norton V4 in front of its Donington Hall HQ

Brand new Ricardo engine

In the meantime, Skinner and his team were also working very closely with the engineers at nearby Ricardo Motorcycle.

With expertise in production and highperformance engines, the government fund assisted in bringing this OEM partner onboard, so enabling Norton to design its own V4 engine.

“I was in their office almost every single day as we packaged the engine alongside the chassis to create a very compact package.

“There are a lot of engineering tricks to make it compact – it’s a big 1200cc engine but the bike is the same size as a 600cc bike. The weight is 175kg with 200bhp so hang on,” he laughs.

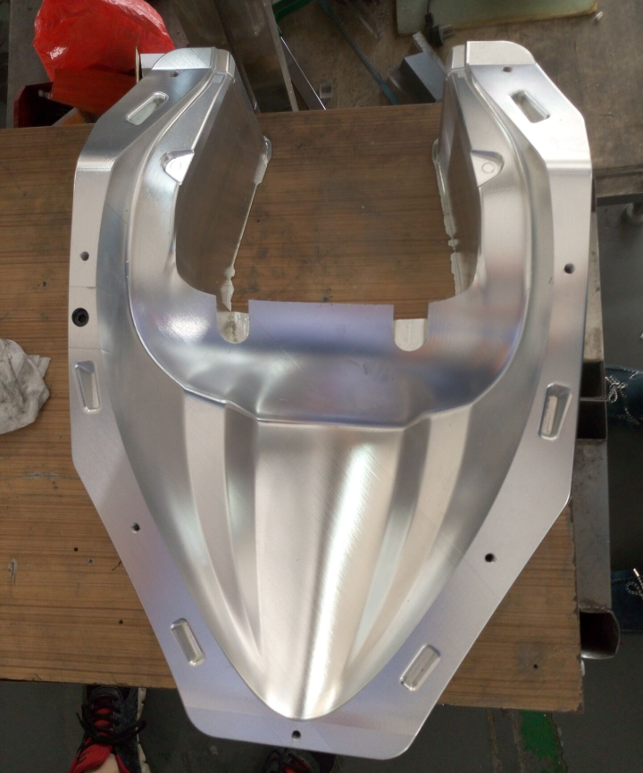

In a bid to save money and time in the design process, the decision had already been made to forgo the clay modelling stage so when the design was complete after six to seven months they went directly to tooling. There is, of course, a risk going straight from screen to a tooled part but Skinner argues that it’s actually cheaper and faster doing it this way.

A typical part created using carbon tooling, which Norton’s head of design Simon Skinner claims is quicker and cheaper than rapid protoyping

“Compared to clay modelling, carbon tooling is relatively cheap and it is very quick. I can tool a whole suite of bodywork for £10,000 in two months – it’s also quicker than rapid prototyping and gives me representative parts. And if they aren’t quite right, I can have another go.”

Nine months in and with Motorcycle Live just three months away, the parts had arrived from the suppliers and Norton’s factory team were busy manufacturing parts and assembling the Norton V4. According to the company, about 80 per cent of the bike is UK sourced or made in-house.

The fully tooled up bike made it to the NEC for its official launch on Norton’s show stand, which received 140,000 visitors over the nine days. “It was a great platform to showcase the bike – it certainly received a fair share of attention and I can honestly say that

we couldn’t have got it there in the timeframe without Freestyle,” says Skinner.

“From a blank sheet to that bike in 12 months that includes the engineering, geometry, frame design, surfacing the bodywork – the whole caboodle from start to finish and I haven’t got 100 people, I had more like ten people working on the bike and the new engine,” comments Skinner.

The man himself, Norton’s head of design Simon Skinner with the finished bike

Measure of success

Having hardly had time to draw breath during the process, is Skinner happy with the result especially the gamble Norton took in skipping the clay modelling stage?

“I think it was 97 per cent successful. There are elements on the bike where the surface is not quite where I wanted it to be and it grates every time I see them. But we sold all the bikes at the NEC and no one has noticed so I got away with it. And if anyone has noticed, they haven’t told me,” he smiles.

“But on the next bike, I’ll know and I’ll make it better and better over time as this way of doing the process is the way forward for us.”

Customers of the all-new Norton V4 will take receipt of their super bikes later this year. The factory has also been kept busy with orders for next year too as the bike has sold out until the end of 2018. “I am sat here with £15 million order book, which is pretty cool. And although there are plans to expand production over the years to 4,000 bikes by 2020, we want to keep Norton as an exclusive, hand-built British brand” says Skinner.

Thinking back to six and a half years ago when we first met Skinner I remember him saying, “There is a big light at the end of the tunnel and the tunnel is getting shorter and the light is getting brighter.” I reckon they are out the other end of that tunnel and basking in the sunshine.

The all-new Norton V4 superbike rockets from sketch to manufacture in just 12 months

Default