Kara Black uncovers how a Texas forge plant is modenising

Trinity Forge in Mansfield, Texas, USA specialises in unique forge and die designs at the requests of its customers, using hammer and anvil tradition with the aid of modern technology.

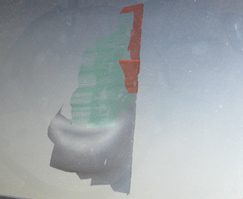

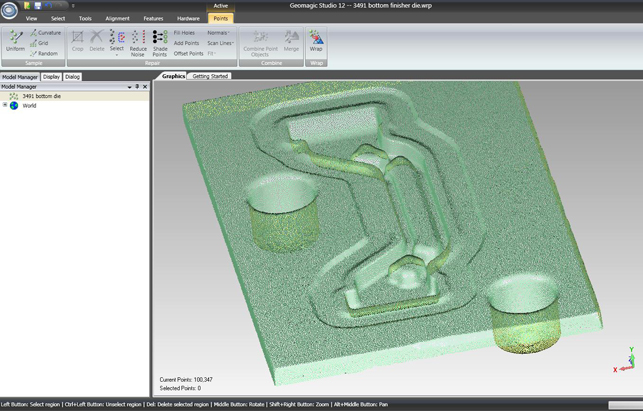

Clean up of the full scan data in Geomagic Studio is easy and accurate

As well as offering heat-treating, machining, assembly, plating, painting, material testing and certification, it’s the first commercial closed-die forge in the United States to receive ISO-9000¬ certification, and has reached precision standards required by the military and aerospace industries.

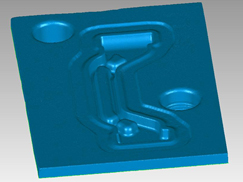

Trinity Forge specialises in closed-die forging, also known as impression-die forging, which involves placinFg metal into a mould with both upper and lower preformed parts called tooling that come together to completely enclose the workpiece.

The process can involve pressing, pounding or squeezing metal under great pressure and usually temperatures as high as 2,300 degrees Fahrenheit.

If a drop hammer is used to force the metal into the entirety of the mould, its striking force can range anywhere from 11,000 to 425,00lbs. Parts can be created as light as a few ounces and up to 100lbs, and typically, forged parts are much stronger than those, which are machined or cast.

Since its beginning in 1955 Trinity Forge has continued to keep abreast of technical advances.

Recently it implemented the use of the FARO Laser ScanArm scanner with the Geomagic Studio and Geomagic Qualify software suite.

¬Todd Sheppard, vice president of quality and engineering at Trinity remarked: “It best suited the high level of scanning and scan comparisons that we intend to do.

“I had seen the product in the past and had heard good things about it.”

Having worked with scanned images for over ten years Trinity Forge quickly obtained a grasp on the main functionalities of the Geomagic software and experienced only a slight learning curve.

“It’s a little difficult to get going, like any high-end software, but we quickly got the hang of it,” Sheppard noted.

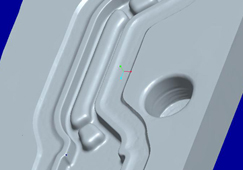

“We use Geomagic Studio on die scans to approve the machining, to compare die wear scans to original die scans, to make part models from a die scan or a legacy wood pattern, to validate machined components for our maintenance area and occasionally to validate tight inspection areas back to our CMM data.”

The ability to validate and verify the quality of all of its manufactured components with Geomagic Qualify has enabled the identification of several errant dies that previously would have been missed.

“We have discovered dies that were machined incorrectly 3-4 times in the past year. One, in particular, we wouldn’t have discovered without the scan,” Sheppard added.

Before using Geomagic Qualify, a project with a machined die would require many hours before it could be verified: two hours to pour a plaster cast of the die and eight hours to allow for curing. Only then could the die be inspected.

With this new technology, the machined die can be scanned, and with Geomagic Qualify, evaluated instantly by comparing the machined die’s scan back to the original die’s scan.

Circumventing the need for plaster casts altogether has been a great time saver for Trinity.

“The biggest savings on making casts is in the reduced time in the shop per die.

“We sink as many as 150 dies per year at an eight-hour average savings per die in time, or 1,200 hours saved in throughput time.

“Value of time and money basically becomes the money-maker here as well as improved customer service, and dies are ready quicker to match customers’ shorter and shorter lead times.” Sheppard said.

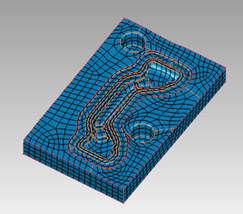

Not only has Geomagic Qualify enabled Trinity to inspect reworked dies by validating the CNC machining relative to the Pro/ENGINEER models, but now the engineers can track die wear by comparing the original die face scan to the current die face scan, or model.

With Geomagic it is becoming increasingly possible to ascertain the time, processes and potential causes of a die’s degradation.

“The way we use scanning it works great for inspection of new dies and better for inspection of worn dies,” stated Sheppard. “We have actually changed die designs based on the information gleaned from these scans.”

On a recent project, Geomagic helped Trinity Forge make crucial decisions for a manufacturer that specialises in the entertainment of children at theme parks.

With this job, the forge dies already existed, and no changes were necessary for the die scan models.

“By scanning the dies and using Geomagic Studio to reverse engineer models, we could get a good indication of where we were at, relative to the tolerances given,” said Sheppard, adding, “It helped us solve the very important issue of material size.

“Getting material can, sometimes, take a while. The sooner we know the size, the sooner we can begin to find that material size.

“The way we did this was use the die scan models in our Deform engineering software, (Scientific Forming Technologies Corp), which enables designers to analyse metal forming, heat treatment, machining and mechanical joining processes on the computer rather than the shop floor using trial and error.

“By doing this we were able to modify our approach to the process and change the material size to something we know would work.”

Before Geomagic, the time necessary to complete the run would have been much more extensive. “In the old days finding out the material size would have been done by waiting until the dies were prepped to run, setting up the dies in the forge shop, figuring -out the billet size and the process of then taking down the setup.

“Next we would have to order the material, modify our process per trial and error and then we could finally make the forgings.

“As you can see we not only saved weeks, probably three to four, of time, but valuable hammer time, probably three hours per setup/tryout, and there would have been two of those at a rough cost of around $5,000 as well as optimizing the life of the dies.”

Trinity weighed in on its favourite functionalities. “Best in Show goes to Geomagic Qualify for its ability to annotate where there are dimensional issues, on the dies themselves, rather than having to go through the entire cast making process and hope we find the problem area when the cast is checked on the CMM,” says Sheppard. “It has been our biggest gain.”

Trinity’s current Geomagic Studio ‘standout’ goes to the “Clean-Up” functionality, with honourable mentions given to the “Mesh Doctor”, “Fill Holes” and “Sharpening Wizard”.

“Every part of the cleanup process in Geomagic Studio is critical,” said Sheppard. “Each process is used and has a place.” Future plans include utilising Geomagic Studio’s Parametric Exchange to transfer models directly into Pro/Engineer from Geomagic Studio without having to create a separate file.

Geomagic has given rise to valuable and ambitious processes at Trinity Forge. “Our goal going forward is to begin to tie it all together.

“We want to scan dies and trim tools and monitor wear of each at incremental scans so we can ultimately have some sort of predictor of die wear and of trim tooling wear.”

www.trinityforge.com

www.geomagic.com

Kara Black uncovers how a Texas forge plant is modenising

No