It is not uncommon to hear of product design consultancies applying their expertise to develop their own product ideas. With the skills inhouse and relationships already established with suppliers and manufacturing partners it’s perfectly feasible, with some personal investment of course.

In order to make the adjustment mechanism strong, stainless steel plates run under the shoes and have the toe straps attached to them

This was the case for John Ewans, managing director of John Ewans Design (JED), a product design consultancy he founded in London almost 30 years ago and later moved to High Wycombe.

Originally trained as a mechanical engineer, and having later studied industrial design at the Royal College of Art, Ewans is also a passionate rower. A few years back he spotted a gap in the market for innovative equipment for rowers. “I thought we have all these design skills that we sell to other people and wondered whether we could use them to develop our own products,” he says.

So he set up Active Tools in 2003 and so far has developed a range of electronic rowing performance monitors and rigging tools, which are not only sold internationally but have gained much praise from both rowers and coaches.

Its latest product is a rowing shoe to replace the ill-fitting, unhygienic and smelly shoes that most rowers in a boat club have to contend with. Bolted into the boat, these shoes are essentially traditional trainers, usually around a size 12, that all rowers using that boat have to use regardless of whether they fit them or not.

“The reality is that rowing is like this; nobody cares about the shoes until they are absolutely disintegrated. It’s revolting,” comments Ewans. “The shoes get wet in the boats which are then put away in the boathouse where they can stay for weeks.

I’ve heard that in Australia when the boathouses are opened all you can smell are the shoes because it gets so hot in there.”

Having experienced these issues first hand, he set himself and his design team the brief of developing an adjustable length, washable rowing shoe. In Spring 2010, Active Tools launched the 2K rowing shoes: tough yet hygienic EVA (ethylene vinyl acetate) foam moulded shoes that can adjust from UK size 9 to 14 (US size 10 to 15).

“We put our money where our mouths were and designed these shoes. It was tricky but it’s also been very interesting,” admits Ewans.

First steps

When Ewans began the project, he did not predict that creating a ‘one size fits all’ rowing shoe would be quite so challenging.

Smaller feet differ from larger feet not only in length but also in height and width. “To cope with the way peoples’ feet vary, we thought of having a wide strap across the middle that fills the gap you would otherwise get when you lengthen the shoes,” he explains.

Having sketched their ideas, silicone rubber mock-ups of the internal shape of the shoes were made.

Being a rower, Ewans could then draw on a number of users to trial the designs, which not only proved invaluable at this early stage but also further down the development process when final prototypes needed to be tested.

However, getting the form right was one thing but it was making them adjustable in length that proved to be the real challenge.

Ewans dedicated an enormous amount of time to building and perfecting the design. “I think there is more engineering in these shoes than in the whole of the rest of the boat,” he laughs.

Push and slide

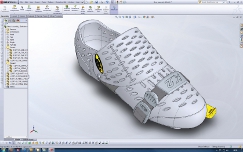

The chassis he designed has two mouldings – a toe and a rear – that slide across one another. To lengthen the shoe, the user pushes down on the yellow lever at the top in order to move the toe chassis.

While it’s sliding, the size can be read in a window display inside the shoe and the lever released when the correct size is visible. The yellow lever is then locked in place when the rower presses down with his or her foot.

Throughout these adjustments, the rear chassis does not move and this is important as it maintains the geometry of the rower’s set up and also prevents the heels being moved into contact with the inner face of the boat, which is extremely delicate. Once the user has adjusted the length, they can then adjust the width by tightening the straps across the top of the foot.

However, if the boat overturns the rower still needs to be able to pull his or her feet out easily.

This is achieved through the use of ties that link through a hoop in the shoe’s heels to the boat, holding the heels down. As opposed to the metal hoops that are sewn into the heels of traditional rowing shoes, Ewans made the hoops integral to the rear chassis moulding so they are immensely strong and cannot rust.

From CA D to prototype

Ewans designed the shoes using I-DEAS from Structural Dynamics Research Corporation (SRDC), the first 3D CAD tool the consultancy invested in almost 15 years ago.

Although it has since invested in SolidWorks, mostly because I-DEAS is now unsupported in its original form, Ewans was the last in the design office to transition over as he still rates the surfacing capabilities and workflow structure of I-DEAS.

In this project, he worked alongside the industrial designer who was using Adobe Illustrator to style the shoe. “The designer would do a line drawing – there would be a side view showing the holes and the shape and I’d put it into I-DEAS and we’d adjust it and work together to get it right in 3D,” explains Ewans.

Being the first of its kind meant that a great deal of prototyping, using both in-house machines as well as sub contractors, was carried out.

“There were a lot of unknowns and it’s the sort of process that if you were a bigger company you would have tooled it, done a prototype batch of 100, put them out there and got feedback.

But for us as a small company it’s an enormous outlay to take that approach so we prototyped one shoe, fitted that to a boat and got various people to test it,” says Ewans.

“Even though we were doing it very cheaply and having parts made in China there was £35,000 worth of tooling – for a small company it was quite a big investment,” he adds.

Testing, testing

As well as extensive user evaluations, JED built a test rig that flexed the mouldings millions of times. This in turn led to revisions in the design including the need for a strap across the toe section.

“We actually built a prototype with just the rubber front moulding but because rowers actually pull themselves forwards in the boat, they need something that is more rigid. The strap also allows them to close down the volume of the toe so if they have a long foot, but a small foot volume, they can tighten it,” explains Ewans.

Extensive testing also resulted in a 316 stainless steel plate being added underneath the toe chassis to strengthen the shoe and ensure that it wouldn’t rip out of the boat.

As Ewans explains, rowing shoes suffer a great deal of abuse when rowers are being taught as they often get their oars stuck in the water during a stroke, which in the sport is referred to as ‘catching crabs’. Rowers can even be ejected from the boat if they catch a very bad crab.

To make the shoes strong enough to survive this, stainless steel plates run underneath transferring the force to the four mounting screws.

“It was very interesting that you can’t make an all plastics rowing shoe. We just couldn’t get the strength using plastic alone. The metal plate not only gives it strength but also provides a mounting point for the toe straps,” says Ewans.

When it came to selecting the material for the exterior mouldings, JED were quite taken with EVA foam, similar to that used in the well-known Crocs footwear, as it provided the soft, washable and flexible material they were after.

However, identifying a manufacturer was difficult as this material is only moulded in India and the Far East and most manufacturers produce copycat products and lack the technical expertise for mouldings of this complexity.

“You can’t really prototype this material because it is foamed. So until you had actually made the tooling and had the real parts you didn’t really know what the product was going to be like, so that was a major concern at the beginning,” confesses Ewans.

Initial challenges

With the initial production batch complete, the first shoes were sold in December 2009. However, JED encountered a number of teething problems and by Spring 2010, Active Tools had launched a slightly updated version following customer feedback.

Firstly, the adjustable chassis was upgraded to an exotic toughened Dupont Zytel ST801 Nylon after a Dutch Men’s Eight, like those used in the Oxford and Cambridge boat race, had a head on collision and broke two pairs of shoes.

“We have had about ten chassis break, all at the same point, yet we had tested the mouldings by bending them four or five million times. We now think that these failures were due to the Chinese moulder using a cold tool for the first shots off the tool,” explains Ewans.

Secondly, the original colour was Active Tools’ brand colour: navy blue. However, following criticisms of overheating in hot countries this was changed to silver.

“In normal conditions they were fine but we had a few comments from people using them without socks (which we don’t recommend) in summer in the southern USA,” says Ewans.

Additionally, water marks turn white when dried and these showed up very clearly on the navy whereas on the silver they are not quite as noticeable.

Lastly, the grade of Velcro was updated to one that provides better adhesion to the mouldings. Although originally Ewans wanted to source an alternative to Velcro, it really did provide the best means of fixing the wide strap to the moulding underneath.

“We tried long and hard to get rid of Velcro but there really wasn’t anything we could find that matched it. Instead we decided to make the straps replaceable,” says Ewans. So, the straps are designed to be clipped on and off and after three to four years, when the Velcro has worn down, new straps can be bought.

Second time lucky

Following the relaunch, the first major customer was the UK national rowing squad who bought them for their new recruits. But despite being on the market for almost 18 months, take up has been slower than Ewans hoped.

However, this could be due to the fact that Active Tools have been somewhat cautious up to now. “I think if it’s your business and you’ve put your own money in, you are cautious until you are absolutely sure it is right. Because it’s not like you are doing a newer version of something that has been done before.

It is innovative and quite tricky so there are lots of things that could go wrong and three things did go wrong. Now that those have been resolved we can really push this now,” says Ewans.

Ewans is confident that once the word spreads and rowers see how much better and long lasting the Active Tools rowing shoes are compared to what they currently use, sales will improve. “I think if they are still looking good in five years time and the other shoes have rotted away we will be able to get 20% to 25% of the market.

But it is a very conservative market – clubs don’t like spending money,” says Ewans. “Also, it’s not like people are looking for innovation.” But so far feedback has been predominantly positive.

For instance, a user at a boat club in London stated that “The shoes have proved a success here; even people who normally complain about everything like them.”

Award winning

The shoes have not only been picked up by the rowing industry but by the design industry too.

In October 2011 they were awarded the ‘Consumer Product Design of the Year’ in the annual Plastics Industry Awards. “We were extremely pleased to have won against such stiff competition and excited that the innovative aspects of the shoes had been recognised,” says Ewans.

A ladies/junior version is now in development and will be launched later this year.

However, this hasn’t been without its hiccups either, as making a smaller version of the man’s shoe wasn’t as straightforward as first assumed. “Women who have a size 8 foot actually have a smaller heel than a man with a size 8. So, with a smaller volume heel you have a problem trying to make it compatible for male juniors.

As a result, we’ve had to cut down the height on the rear of the shoe,” says Ewans.

So has all the investment both in terms of money and effort been worth it? “Absolutely,” says Ewans. “As well as creating a company that is beginning to make useful profits we have become much better designers since doing our own products.

We are now more realistic, confident, and can also empathise with our clients more because we have been a client ourselves.”

“One size fits all’ rowing shoe from Active Tools

Default