Whichever way you cut it, creating 3D products is an involved and complex business.

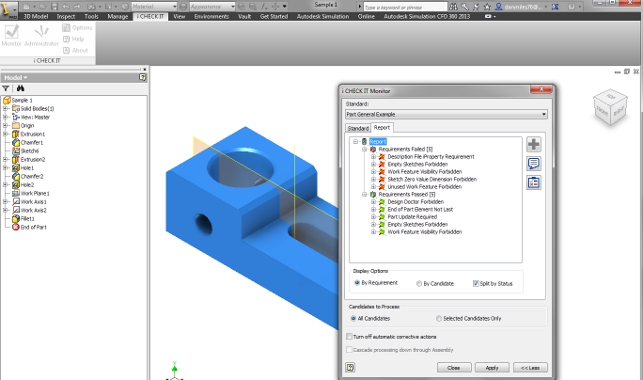

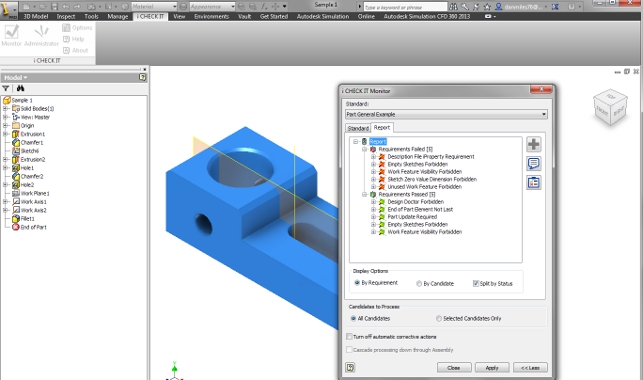

i Check IT standards can be applied to parts, assemblies and drawings from within Autodesk Inventor

Problems in product development can arise from a variety of areas such as errors or bad practices in a model’s construction history as well as nonconformance to standards.

Not least when the data is inputted into a data management system, which thrives on the use of structured and complete metadata.

Project and part naming conventions, descriptions and classifications all feed into building a searchable and usable system. If a user doesn’t adhere to the defined requirements or conventions, then information can’t be found or reused and the whole process falls apart.

So, how can an organisation go about ensuring that the benefits of both 3D design, 2D drawings and data management are gained to their fullest extent?

i Check IT from Tata Technologies is a system that integrates into both Catia V5 and Autodesk Inventor to automate the checking of part and assembly models as well as drawings to ensure that they adhere to the standards and best practices defi ned by the user.

It’s split into two areas: the administrator application, in which standards and checks are defined, and the monitor application, which works inside each user’s CAD seat.

Let’s start with setting up the system, which in this case is carried out in Inventor.

Defining best practices

The user begins by defining standards. This is a process that combines both choosing from a large list of provided checks and configuring the user’s personal checks to establish a standards file.

When working with Inventor, the system is supplied with over 120 different checks. These range from the basics, like ensuring file name and properties are properly defined, to carrying out sketch-based fundamental checks.

It then looks at part feature order, feature size and whether suppressed features are present. Other checks include whether the part has been updated before saving and whether there are any empty sketches.

At this point the user needs to decide whether to include this into their best practices. When it comes to drawings, these include ensuring that no dimensions have been overridden, that dimension styles are adhered to and that title blocks are filled out.

In order to build custom checks, Inventor users have iLogic whilst Catia V5 provides access to over 300 provided checks.

Once the standard files have been created, they are commonly stored on a network allowing all users to access the standards from one place.

Best practices in use

When installed into Inventor, i Check IT connects each user to their organisation’s set of standards.

It’s used in three different modes. The first is the Manual method. This requires a decision from the user to check their work, whether at the end of the day or when a part or project is complete.

If the user can define how models, parts and drawings are defined, they can save administration time and remove many of the problems that centre around making design changes

As the parts are checked, the system flags up any errors. Some checks can be fixed automatically, but others will require intervention and editing of the model.

Each check shows the user where the problems exist and gives enough guidance to get things ship shape. It can then be saved or checked into the data management system. Reports can be generated to confirm that this has taken place.

The second use model is Batch mode. This allows the processing of a set of files in one go, whether from a day’s work or at any stage in a project. i Check IT runs through the checks and creates a report for each.

The third mode is connected with the Autodesk Vault and triggers from an event or workflow. This is very interesting as the user can automate the checking process server side, which ensures everything is correct before being released to manufacturing.

For example, if a part moves to a released state, the system will run the checks and only allow that state change if they pass all the checks.

There is also a PDM framework integration for the Catia V5 version of i Check IT that allows the user to automate checking within the most common enterprise PLM solutions like Teamcenter and Enovia.

Conclusion

Best practices are something that many organisations consider, but few rarely get around to actually defining and implementing.

Why? The answer is complex but often can be distilled down to two things; finding the time to define them and finding a way to implement them.

This is the challenge that systems such as i Check IT look to solve. If the user can define how models, parts and drawings are defined, they can save administration time and remove many of the problems that centre around making design changes. In turn, the data management system becomes much more efficient.

Thirty day trails can be downloaded for both Catia V5 and Inventor. It’s worth a look.

| Product | i Check IT |

|---|---|

| Company name | Tata Technologies |

| Price | on application |