SpaceClaim occupies an interesting position in the product development software market.

At present, the system is gaining ground in various places and making inroads against established players.

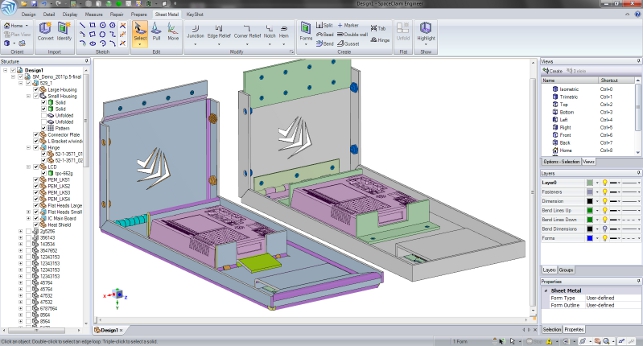

A conceptual sheet metal part redesigned in SpaceClaim to reduce the number of components from seven to two and the number of separate fasteners from eighteen to four

While the numbers of sales aren’t divulged, we’re certainly seeing more SpaceClaim users registering with DEVELOP3D — and that’s always a good indication. But why is this happening now, four years since its initial release?

One answer is that the organisation has added functionality that’s transformed the system from being an interesting new technology to something that’s eminently usable.

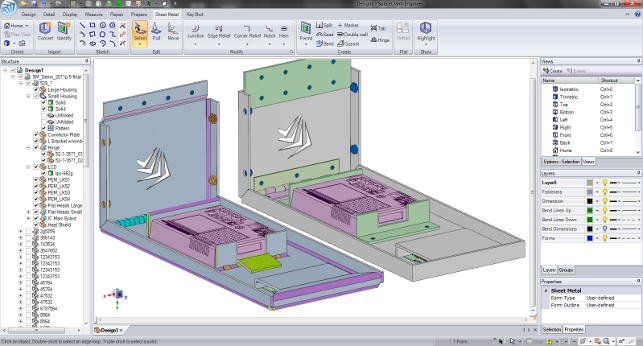

For those that haven’t seen the system working, SpaceClaim’s user interface is certainly compliant with the expectations of today’s users.

The Windows UI is in place, the commands and operations are organised by tabs for design, for detailing, for view manipulation, then into more specialised areas such as model prep for Finite Element Analysis (FEA) and sheet metal. And within each, the commands are sub-divided into clearly labelled groups.

SpaceClaim is maturing nicely with more specialised capabilities being added with each release alongside expansion of generally applicable tools. And as it does it should become more and more interesting to a wider range of users

When it comes to part and assembly design, SpaceClaim is an unabashedly direct modelling system. There’s no use of history and the geometry creation process is driven by the use of informal

sketches for initial geometry creation, which is then followed by the pushing and pulling of faces and edges.

For those with a background in parametric design tools, it takes a little getting used to, but once you get the ‘hang’ of it, you’re away.

Geometry (both individual faces and multiple selections) can be manipulated (moved/rotated), fillets added, cuts and additions made with ease.

One thing that is worth noting is that the system isn’t free of features entirely. In the general modelling tools, these are used to define features such as shells, patterns and such, but they’re by no means stored in a traditional sense — which we’ll get onto shortly with the sheet metal functionality.

So how about we dive in and see what’s new for this release? Let’s go.

Sheet metal

This is a huge release for those working with products with a heavy sheet metal content. There’s a big difference between a CAD system that claims to have sheet metal tools and one that can actually deliver on a production job in terms of design.

SpaceClaim, as long time followers will know, has an agreement with Trumpf, one of the leading machine tool vendors in the space. It’s also clear that the driving force for the capabilities within SpaceClaim has come from both customers and Trumpf itself.

There are now tools that allow you to take a constant thickness part, convert it to sheet metal, then work through things to create the rips, breaks, bends and such to flatten it. There is also much greater support for complex sheet metal features, whether that’s double walls, hinges, gussets and many others.

Documenting design

While SpaceClaim is undoubtedly a geometryfocussed system, the facts are that whoever uses it — whether that’s a full time CAD user or an occasional user prepping models for simulation, preparing a quote or adding machining stock — they need to be able to document the geometry.

The last few releases have seen the detailing and documentation tools increase in their sophistication and this continues with 2011+. In addition to the existing tools, you can create offset cross sections, add hole tables and hole markers, datum targets — even bring in external model drawing views.

Communication & interop

Another of SpaceClaim’s strong points has always been interoperability. Not particularly in the realms of being able to convert data (though some have found it particularly useful for this), but for being able to take data from almost any source and work with it.

Alongside an impressive raft of import options for native CAD data (such as Pro/Engineer, SolidWorks, Solid Edge, Inventor, Catia) SpaceClaim can also bring in more standard files, such as STEP, IGES, STL. The 2011+ release adds the ability to read in JT data along with its Product and Manufacturing Information (PMI) data.

Conclusion

SpaceClaim is developing nicely, with two pretty major releases each year. In terms of pure geometry handling and capabilities, the rate at which it’s catching up more mainstream developers is impressive — and worrying for those longer established players. But a system like SpaceClaim isn’t for everyone.

There’s a reason that history-driven systems are more dominant. They offer more flexibility when it comes to working with more complex products, more complex geometry.

This is just as true of CoCreate (or whatever PTC is calling it these days) as it is of SpaceClaim.

SpaceClaim doesn’t excel because you’re free from the baggage of history-based modelling, it does so because that reliance is removed and you have a much freer experience — one that you can typically retain as you’re manipulating the geometry directly. Moving and rotating faces, sketching in the geometry you want and positioning it where it’s needed.

SpaceClaim is maturing nicely with more specialised capabilities being added with each release alongside expansion of generally applicable tools. And as it does it should become more and more interesting to a wider range of users.

After all, there is still a need for a system that is pretty much ready focussed on creating geometry because sometimes, all you want to do is get the job done and move on.

| Product | SpaceClaim 2011+ |

|---|---|

| Company name | Spaceclaim |

| Price | from $2,445 |