A line-up of the customised classic sports cars PGO Automotive produces

Most cars on our roads are produced by a handful of global companies that mass manufacture thousands of models a year in factories all over the world.

At the very opposite end of the scale is the exclusive sports car manufacturer PGO Automotive, where, based in the South of France, only 300 hand assembled cars leave its factory every year.

Its models, of which there are four, are the haute couture of the car world. Although they may look retro they have a very modern specification.

“Our goal is to create vehicles that have a vintage look thanks to the adoption of simple, pure and unadorned shape, but have all the modern features that our customers expect such as ABS, airbag, infotainment system, GPS etc.,” says Nicolas Urffer, studies manager at PGO Automotive.

The brand’s legacy is in producing replicas. Set up in 1985 by two car fans whose initials formed the brand – Prévôt Gilles and Olivier – it started out by manufacturing kit cars, specifically the Cobra and Porsche 356, but then moved on to creating its own designs and became a manufacturer in its own right.

The company only has 50 employees and there is no separate design and technical department; being a small team the designers and engineers work side by side. They also work extremely closely with the craftsmen in the factory. “We communicate weekly with the workshop on future improvements, new products or next evolutions.

Every day members of the department work with the craftsmen in the factory,” comments Urffer. As each car is customised, attention to detail is paramount. “We pay a great deal of attention to the overall quality of the vehicles we deliver, in particular the quality of the paint finishes and upholstery. All the upholstery, like the assembly of our cars, is hand made in high quality leather for example,” adds Urffer.

The design and engineering office with a table displaying the colour and accessories options

From sketch to CAD

A new model will be in development for around three years from first pencil sketch to the start of production including all the regulation tests that have to be carried out.

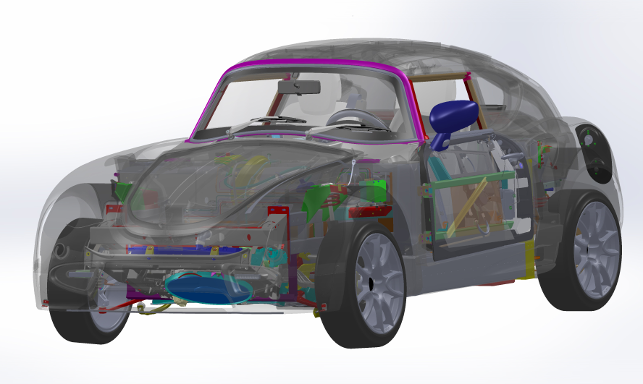

“After the sketching phase we choose two or three avenues of research and then develop those by adding all the technical constraints. In this phase we start to create the shape in our CAD software SolidWorks.

“We use SolidWorks for pretty much everything – surface moDelling, rendering, analysis… However, for some very specific work like electrical design or crash test simulation we’ll use partners. As this work is really specific we prefer to work with a specialist in this domain,” says Urffer.

For bigger car manufacturers, producing a life-size clay model is an important part of the development process.

Being a malleable material, the designer can easily use the clay to create the desired shape and form of the car’s exterior. Life-size clay models are out of reach for a small company like PGO and although it’s still an important part of the process, they produce smaller scale models instead.

“After the validation of the digital model in SolidWorks we make several scale clay models in order to validate the general volume. We can sometimes machine full-scale parts but never the whole car,” explains Urffer.

They then use a ROMER 3D scanner to scan the clay model and the resulting point-cloud data is brought back into SolidWorks so the designers can work on the digital model. “We also use the 3D scanner for reverse engineering (for the parts we buy and for which we haven’t the CAD files for) or for inspection and validation of parts,” he adds.

To create renderings of the model the design team use SolidWorks’ rendering tool Visualize with its design-oriented features and workflows. This tool allows the user to change settings interactively while displaying them in a viewport at the same time.

Depending on the level of detail required, the viewport can be used in ‘Preview’ mode, offering an interactive workflow with a decent quality preview. Alternatively, changing to the ‘Accurate’ view mode brings the Nvidia Iray technology within SolidWorks Visualize into play and creates a photo-real image within the viewport.

The Hemera model moDelled in SolidWorks

Hardware upgrade

However, to render a car exterior with metallic paint could take over 50 minutes on their workstations’ CPUs.

In a bid to save time, PGO decided to upgrade its hardware and invested in a Dell Precision R7910, equipped with Nvidia Quadro M6000 GPUs. As a result, rendering time was cut fivefold to less than five minutes.

“The new SolidWorks Visualize tool in combination with the Iray technology from Nvidia and powered by a workstation from Dell has saved us many hours.

Our designers can work on the full model directly in the ‘Accurate’ view mode of the Visualize viewport and results can be seen in the viewport immediately in great quality.

“We can control lights and shadows interactively to create the realistic renderings we need in far fewer iterations,” comments Urffer.

Creating renderings using the new Dell workstations has significantly slashed design time

Digital validation

PGO soon realised that the Visualize tool with its interactive workflow could be used a lot earlier on in the development process too, giving the designers an interactive review capability whilst working with the CAD design files.

From simulation of different colours to fault detection in the car body design, the interactive photorealistic rendering will help them make the right decisions earlier on in the process.

“Digital validation is faster than conventional prototyping and also cheaper. We are not working with large clay models and now we have the possibility to really use the digital prototypes to see how the future car will look. We can see how the body will look and can make immediate decisions to make our new design as good as possible. Both functionally and visually,” comments Urffer.

For this stage of the process, PGO chose the Dell Precision 5810 workstation with the Nvidia Quadro M5000 GPU. This system enables a 4k interactive car model display which can be altered as needed on the fly.

“All validation can be done interactively now. We can work on the model data, change and display it as needed” adds Urffer. “Whether we are in a design discussion, use the rendering for an internal presentation or updating our shareholders on a new design, we have a solution at our fingertips that works perfectly for us.”

A high resolution visualisation of the Hemera model using SolidWorks Visualize

Interactive configurator

With this new combined software and hardware capability, the PGO team set their sights on a state-of-the-art interactive configurator with layered renderings that would be implemented on its website and would allow customers a range of interior and 360° exterior views of their customised vehicle.

“Last year we did a beta version of our car’s configurator and we had only positive feedback form our customers and distributors,” says Urffer.

The company is also looking to virtual reality. While a cave automatic virtual environment (or CAVE system) has been used by the bigger car manufacturers for some time, these large, costly systems are not financially viable for smaller producers.

“We would like to integrate a virtual reality solution inside our company very soon. It could be an opportunity for our development team or for our customers.

“We can’t afford a CAVE system but over the past few years we have seen the emergence of head mounted display technology like the Oculus Rift or HTC Vive. We have to be smart…”

PGO Automotive saves valuable time in development

Default