The Lamiflex Group, based in Bergamo, Italy has for over 30 years supported various industries with its high tech composite materials. The company started production in 1976 with the development of rapier ribbons, which were made from composite materials for the textile machinery sector.

With its oversized wheel and carbon fibre frame, Ciclotte certainly breaks the mould of traditional fitness equipment

Through constant research and investment Lamiflex has since expanded into other market sectors, such as aerospace, where it uses a special ‘autoclave polymerisation of composite materials’ process.

Certified by helicopter manufacturer AgustaWestland, this process produces both stiff and flexible lightweight ducts for ECS systems installed in aircraft or high performance vehicles and machinery used by the military.

Over the years, the group’s technological innovations in production and research have led to its current position as a market leader in the field of technical composite laminates.

Composite materials are, by definition, structures made up of several component materials, typically thermoset resins strengthened with carbon, Kevlar or glass fibres, which provide certain characteristics (usually mechanical) and a matrix that holds the fibres in position. This not only gives protection but also offers other specific characteristics for particular applications.

Laminated composite materials can be produced as sheets of continuous strands of fibre, layered so that each fibre lies in a specific direction. This means that reinforcement is only added where needed so the amounts of material used can be optimised and, as a result, the weight of each product kept to a minimum.

The main purpose behind the development of composite materials is, without a doubt, their high ratio between density and mechanical strength. This gives them performance levels similar to those of metal (or even higher) but at far lighter weights (50% less).

On yer bike

In 2009, Lamiflex were involved in the development of an innovative piece of fitness equipment designed by Italian product designer Luca Schieppati. The Ciclotte exercise bike has an ultra-modern carbon fibre frame, touch screen display and reduced pedal distance to ensure the correct biomechanics throughout the complete leg rotational movement.

The large central wheel forms the cornerstone of the design and is reminiscent of the classic unicycles dating back to the end of the 1800’s. However, due to its cutting edge engineering and design aesthetics, the Ciclotte has become a desirable object in the world of interior design and luxury fitness.

The bike has been designed to faithfully reproduce the dynamics and performance of on-road pedalling. As such it’s ideal for high intensity aerobic training, such as ‘spinning’, especially with the inventive epicycloid crank system.

A dual satellite system that uses four gears with varying cogs in a functional space of only 58mm. By multiplying the number of flywheel rotations – about four flywheel rotations to every pedal rotation – it helps generate a high-intensity magnetic field (from the main wheel). This maximises the resistance level and produces plenty of thighburning resistance.

Follow the leader

The Ciclotte is a follow on from the Ciclò project, an innovative prototype of a single wheel city bike, which is now part of the permanent collection exhibited at the Triennale Design Museum in Milan.

“The concept from Luca Schieppati excited our company and we wanted to help bring the product to life using our vast experience of modern composites,” explains Federico Carrara Castelli, R&D director at Lamiflex and Ciclotte project leader.

At the beginning of 2009, a first aesthetic prototype was produced to test the market feedback before moving onto a fully functional prototype. To guarantee the exact requirements and size of all functional mechanical components, including the carbon-fibre handlebar and saddle, all components were designed in 3D and simulated as a virtual assembly.

This highlighted any potential issues prior to the assembling procedure, which brought over 60 separate components together.

Move to CADCAM

To coincide with the Ciclotte project, Lamiflex also took time to evaluate the software market and invest in a new integrated CADCAM system.

“Previously at Lamiflex, we used a parametric CAD system that we found difficult to use and quite restrictive when working with complex organic surface forms”, explains CAD designer, Marco Perani. “After extensive benchmark testing, we decided to implement VISI from Vero Software as we believed it offered the best balance between performance and price. We are currently running multiple licenses of VISI Modelling and VISI Analysis for Design, and VISI Machining with Compass Technology for 2D through to 5 axis milling.”

“We have used VISI for the design and manufacture of all composite mould parts that were used to build the Ciclotte. With regards to the moulds for the carbon fibre wheel and the handlebar, all of this was achieved in less than 100 hours of CAD work,” adds Carrara.

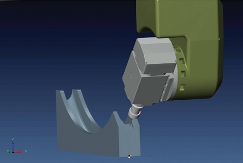

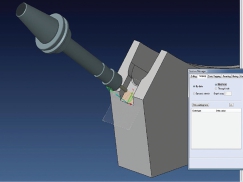

Lamiflex run several milling machines including two simultaneous 5-axis CNC’s running VISI Machining

Once the moulds were complete (and polished), the fabric and epoxy resin are applied. They are then inserted into a vacuum bag and placed inside the autoclave for the curing process. Once hardened, the parts are then passed through to the CAM department for finish machining.

“At Lamiflex we run several milling machines including two simultaneous 5-axis CNC’s running VISI Machining,” explains Carrara. “For the finish machining of the composite products, the ‘trimming’ method is often used, where the side of the tool is driven along the surface edge.

For additional control, synchronisation curves can be used to control the tool movement in local areas where the potential direction changes are at their most extreme.”

“For the machining of planar holes, the tool is tilted perpendicular to the surface, but when product holes are difficult to reach, an extra tilting of the tool is required in order to avoid collision with the tool holder. When the toolpath is complete, the machine operator is able to virtually walk through the complete program using the kinematic simulator and prove the toolpath is collision-free,” comments Carrara.

Fit the bill

Concluding, Carrara states “Introducing the software has streamlined our manufacturing processes, reduced the potential for error and ultimately increased our productivity. We are a company always looking for innovative, often revolutionary solutions and consider Vero to be an important partner in this philosophy.”

The Ciclotte was officially launched in the UK towards the end of last year to rave reviews. It is available in three versions, full carbon, silver (fibreglass) and steel, for the approximate price of £8,000.

www.vero-software.com

www.lamiflex.it

Vero Software eases the design/build of revolutionary exercise bike