It’s not everyday that you get the opportunity to have a sneak peek into the inner workings of a legendary sports car manufacturer.

The Ferrari 458 Italia was recently named by Auto Express as the ‘Performance Car of the Year 2011’

But this July Ferrari opened the gates of its Maranello headquarters in Italy to honour the winners of the Ferrari World Design Contest 2011.

Although we were steered well away from the more secretive areas such as the clay model shop and anything related to the design of its Formula One cars, it did provide an insight into how this celebrated sports car manufacturer designs and produces its cars.

Officially founded in 1947, Ferrari has produced some of the world’s most iconic cars that most of us can only ever dream of owning. And it’s still on the same site where the entire process for both the GT and F1 cars takes place, apart from the production of the GT chassis and bodywork which happens at a facility in nearby Modena. The site is vast, occupying a total surface area of 551,519m2.

When entering the ‘New Mechanical Machining Area’ building, where Ferrari’s 8 and 12-cylinder engine components are made, the first thing that strikes you is how the machine tools are regularly interspersed with green foliage. This is all part of Formula Uoma, a major renovation programme introduced by Ferrari in 1997 that focuses on providing employees with a stimulating, attractive, safe and ecological working environment.

It obviously paid off with the Financial Times recently naming Ferrari as one of the ‘100 Best Places to Work in Europe’. The ‘New Assembly Line’ building, which is another light filled space, opened in 2008 and is where the V8 and V12 cars are assembled.

It features a carousel system, produced by Italian robot manufacturer Comau, which moves each car’s body along, sometimes even overhead, through a series of workstations until it emerges as a fully assembled car at the other end.

The bodywork enters the system with a trolley alongside it containing all the components needed for that specific vehicle. It stops at each workstation for 20 minutes with each one ergonomically designed and height adjustable to suit the individual needs of the workers. Although a great deal is done by hand there is also some automation such as a rather nifty robot that fits the windscreens onto the cars.

Styling the future

Round the corner is the Product Development Centre building, which houses a number of offices including the design office.

It is here where the Ferraris of the future are styled. The designers here often work very closely with the Italian car design firm Pininfarina, which has partnered Ferrari in the styling of its cars for six decades.

Flavio Manzoni, Ferrari’s design director, admits that although being a Ferrari designer is a great job it’s also extremely challenging to create “dreams and masterpieces of the future.”

As his colleague Andrea Militello, Ferrari’s exterior designer, puts it: “It is a difficult balance because on the one hand it has to be undeniably a Ferrari but at the same time it has to be something completely new and shouldn’t look like something that has already been done. It’s very, very complicated.”

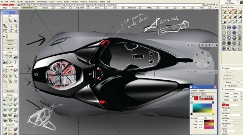

The design process always starts with sketching. For Manzoni, the ability to capture ideas, dreams and emotions with pen and paper is fundamental in automotive design.

“Our relationship with Autodesk is very important. They can offer the software and the tools to transform these sketches into something real. But no software, no computer could ever replace the hand,” says Militello.

Once the surface has been created in Alias, the data is used to mill a full size clay model. According to Manzoni, although being able to model a car in 3D reduces the development time they wouldn’t rely solely on virtual prototyping.

“Despite the huge evolution of these kind of tools it’s really difficult to evaluate the proportions of a model in just a virtual envioronment. It needs the physical delivery,” says Manzoni who estimates that a minimum of one clay model is made per month.

Manzoni does hint that Ferrari is looking to use virtual reality in the design process. This basically entails using a projector to beam a life-like 3D holographic model into a room that floats a few feet in the air enabling the designers to walk around it scrutinising both the design of the interior and exterior, much as they would a clay model. “This would be the best but we will have to wait a little bit for this,” he smiles.

For now, changes to the models are made manually on the clay model. A laser scanner is then used to capture the data, which is then checked and updated on the computer. As the model evolves, the engineers, who use ICEM Surf, and the designers start working more closely together.

Although not based in the same office, they are constantly interacting and collaborating with one another as input from the engineers may impact certain styling elements of the exterior. “I think this is one of the few companies where this collaboration works best.

The technicians understand our request of selling emotions and dreams and we understand their request of achieving technological excellence in aerodynamics and lightweight designs. It works very well,” says Militello.

Additionally, with a wind tunnel onsite aerodynamic testing on the model can be carried out there together with Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) carried out on the computer. “As soon as we get a new form in 3D our aerodynamic experts can start testing it immediately,” explains Manzoni.

Talent show

Although Ferrari has launched a string of successful GT and sports cars in the past few years, including the California, 458 Italia and the Ferrari Four, what will future Ferraris look like? One way of forecasting what the future may hold is to see what ideas future automotive designers are thinking about. This was one of the reasons behind the Ferrari Design Contest. “Why students?

We believe in young people – some brilliant ideas come out of students. An idea could become a cue for a new design,” says Manzoni, who instigated the contest a year and a half ago.

The competition was launched in collaboration with Ferrari’s technology partner Autodesk and challenged transportation students from 50 international schools and universities to use the latest technologies and materials to create a Ferrari of the future.

“We gave the students a very precise brief asking them to imagine and design a hyper car for the third millennium,” says Manzoni. “It had to be hyper light, hyper fast, hyper technological and hyper ecological. But the car not only had to be very fast and include new technology it also had to be in line with our brand.”

It’s not surprising that over 200 projects were submitted when the prize up for grabs for the students in first and second place would be an internship at Ferrari.

The jury whittled the projects down to just seven schools: Istituto Europeo di Design (IED) in Turin and Barcelona; IAAD – Turin; College for Creative Studies – Detroit; DSK International Design School – Pune; Jiangnan University – China; Hongik University – South Korea; and the Royal College of Art (RCA) – London. Each of these schools submitted three concepts, which included 3D models created in Alias and 1:4 scale physical models.

So, at a rather glitzy awards ceremony at Ferrari HQ in July it was three students from Hongik University who walked away as the grand prize winners for their Eternita concept. The judges felt that this concept provided the best interpretation of the design brief and the most innovative use of future technology.

Features include light-layered carbon surfaces, a physical fl ywheel energy storage system, a superconductive motor and a hydrogen generator.

Second prize went to IED of Turin and third to the RCA. A further two prizes were also awarded – the Autodesk Design Award went to Hongik University for their innovative use of Alias design software and the ‘Most Unexpected Technological Solution’ award was presented to Jiangnan University.

Ferrari’s chairman, Luca di Montezemolo, closed off the ceremony by saying how Ferrari likes to get involved in initiatives such as this in order to keep its windows open to the world.

“I saw first hand the many genuinely innovative ideas that these talented youngsters sent us and could feel the enormous passion and commitment that had gone into them. I am certain that some of these suggestions will come to light in the Ferraris of the future.”

Students design a hyper car for the third millenium

Default