For over 50 years, Austrian brand KTM has been designing and developing motorcycles.

he KTM 1290 Superduke R prototype was launched in November 201

Initially it was off-road models but in 1994 the company expanded into street motorcycle production. In 2008 it even diversified into the four-wheel market with the launch of the high performance sports car – KTM X-Bow.

But no matter what comes out of its factory doors, all models embody the company motto of ‘Ready to Race’.

Located nearby KTM’s headquarters in Mattighofen is Salzburg-based KISKA Design and, for the past 20 years, it is here that all of KTM’s motorcycles have been designed. KISKA CEO Gerald Kiska founded the company in 1990 and although it is now made up of over 140 creative professionals from 21 different nations, back then it was a one man business and KTM was one of its first clients.

“KISKA has been designing for KTM for over 20 years and I am still KTM’s chief designer.

The work we have done in partnership with KTM has allowed it to become one of the most respected brands in the motorcycle industry,” says Gerald Kiska.

More than motorcycle design

KISKA however, is not just responsible for the design of the motorcycles, it is involved in virtually every KTM design and communication project.

Activities include clothing design, market research and market positioning, consulting, digital communication, product graphic design, communication design and advertising campaigns as well as trade shows and shop systems.

“We are intrinsically involved in ensuring that the design and communication speaks to the ‘Ready to Race’ brand promise – from the logo, to the website, to the next KTM X-BOW,” explains Gerald Kiska.

“It is satisfying to see the brand develop and to understand how adjustments, both dramatic and minute, can affect its position in the market.”

Responsible for this myriad of activities, for KTM and a range of other clients too, KISKA ensures it is kitted out with all the latest tools and processes.

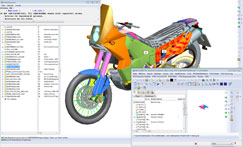

On the software side it has a wide variety of graphics and CAD tools from Autodesk products to Rhino, Pro/Engineer, Catia and SolidWorks.

It also has a fully equipped 1,000 square metre design and engineering workshop that allows for large scale 1:1 modelling, clay modelling and the development of functional prototypes.

1290 Superduke R Prototype

KISKA has been involved in over 100 motorcycle design projects for KTM with the most recently completed motorcycle being the KTM 1290 Superduke R prototype.

Unveiled at the Milan Motorcycle Show (EICMA) last November, this prototype is based on the KTM Superduke naked bike and is powered by a 1290cc version of its RC8 R liquid cooled V-twin engine.

The design of the prototype actually began with this RC8 R engine, which produces 129 kW and 120 Nm torque.

The designers then evolved its predecessor – the KTM 990 Superduke – by giving it a more ‘souped up’ feel with a shorter distance between the handlebar and seat.

Other features include a trellis frame made of chrome molybdenum steel, a single sided aluminium swing arm, upside-down forks with gas pressure reservoir and front and rear Brembo racing callipers. All in a carbon fibre package that weighs just 185kg.

“When the first Superduke arrived on the market it was quite surprising at the time as it had a radical edge to it. Now, a few years later and, sure, you need to increase the ‘wildness’ a little bit, but technically it is the same idea and the same direction,” says Kiska.

“We definitely looked at what people are attracted to nowadays and it is not only the displacement; a bike needs to turn people’s heads and help individuals express themselves. This is a real bike.”

Perfect weapon

As might be expected, many of KISKA’s employees are ‘petrol heads’ themselves and as such the KTM Superduke 1290 R prototype expresses the true nature of the people behind its design and development.

“This is definitely the bike that we have built for ourselves – for the curving roads around Mattighofen and Salzburg this is the perfect weapon!

“When we got to ride the first prototype with the engine configuration that we presented in Milan we were all blown away. It is definitely the most fun that I’ve ever had on a motorbike. It is so torquey,” describes Kiska.

When it came to the styling of the prototype, the challenge was to not only portray the increased performance of the engine but also ensure it maintained that signature KTM DNA.

“It is a big bike but we wanted it to look delicate and for that we stripped a lot of the plastic away so you can see more mechanical elements, more of the frame and engine. We wanted to show the ‘promise’ of the 1290,” says Kiska.

Prototype to production

KTM and KISKA have made no secret that this prototype will become a production reality, which is set to be unveiled during the autumn.

The public did get a taste of ‘The Beast’, KTM’s nickname for it, during July’s Goodwood Festival of Speed held in West Sussex, UK, when former MotoGP rider Jeremy McWilliams took it for a ride.

McWilliams had this to say before embarking on the 1.16 mile hillclimb course: “It’s always an honour to ride at Goodwood, but to be honest this will be the most insane bike I’ve ever ridden and yes – more than a certain MotoGP bike.

Hopefully I can keep ‘The Beast’ on a leash and put on a good show for the fans at Goodwood. It is going to be memorable!”

Surely then, of all the KTM motorcycles KISKA has designed, the 1290 Superduke R Prototype must be Gerald Kiska’s favourite?

“Asking me to decide my favourite KTM bike is like asking a winemaker to decide which wine he has made is his favourite!”

“I am proud of every bike KISKA has designed for KTM over the past 20 years and look forward to finding new ways to express the ‘Ready to Race’ brand over the next 20 years.”

kiska.com | ktm.com

KTM’s path toward Product Lifecycle Management (PLM)

Since 1998, KTM has been using PTC’s tools to assist with taking its products from concept to manufactured item. The journey began in 1998 with the company investing in Pro/Engineer.

Previously, it had been using a little known 2D system called Caddy and Cimatron for its 3D work.

With the wealth of data created, the team realised in 2001 that some form of data management was required and adopted Pro/Intralink for managing its design data across the whole company.

This sufficed for the next few years until data had grown to the point where something more sophisticated was required.

Partially driven by the sheer volume of information, but also the need to expand out the types of information stored and increasingly complex products, a decision regarding a move to either PDM/Link or Windchill was made.

The key requirements were that the PES (Product Engineering System) would not only hold its wealth of engineering data, but also replicate its existing workflows and approval processes in a digital environment.

Another key driving factor was greater integration between the PDM system and the company’s chosen ERP (Enterprise Resource Planning) system, Movex.

An environment that combined PDM/Link with not only Pro/Engineer, but also ProductView was put together and rolled out across KTM’s internal departments.

This also allowed supply chain access to released data in a controlled and secure fashion. The PES went live in 2008 and in the intervening years, KTM has been updating and expanding the solution.

At present, the PES system is available for use by 580 users. In terms of how this breaks down, KTM has 170 CAD-using designers and engineers,

125 members of the team involved in release workflow, sign off and approval (not including manufacturing and production staff) and 285 pure viewing users who are not involved in the approval process.

In terms of departmental coverage, it’s now in use in R & D, purchasing, scheduling, production, AV, technical documentation, customer service, quality and more.

In the last two years, KTM has also moved further. The team is now looking to bring not only technical documentation into the managed data realm (using Isodraw and Abortext), but also to introduce the management of cable and harness design using the Pro/Engineer interface with Zuken Pro/Cabling.

KTM is also looking to expand out its use of 3D visualisation (using ProductView) to assist with the approval process. Additionally, Variation management is on its current to do list.

Into the future

Next year’s aim is to make the move to Creo 2.0 (the team has highlighted the use of sub division surfaces in Freestyle as a driving factor) in combination with an upgrade to PDMLink 10.1.

Beyond that, the team is looking to link its CAD product structures with an electronic BOM (bill of materials).

The design and development of the Superduke 1920 R prototype

Default