Born from Helvacıoglu Kahve’s coffee-making expertise and Pininfarina’s flair for design, the new Levee espresso machine aims to give professional baristas the tool they need to extract the very best beverage. Claudia Schergna speaks to the team behind the design

If you ask an Italian barista why they chose the espresso machine they’re using, there’s every chance you’ll be listening to a story laced with sentiment for the next half hour. A coffee machine is never just a coffee machine.

While built from cold steel and copper pipe, a machine embodies status, family history, tradition and loyalty. Many coffee lovers choose to become regulars of a bar just because of the espresso machine used there.

A market like this is therefore not an easy one to enter if you are new to the game. And this is something Helvacıoglu Kahve was aware of when it started working towards launching its own coffee-making appliances.

One of the most recognised coffee roasters in the world, Helvacıoglu Kahve was founded in 1926 as a food company. After specialising in coffee during the 1980s, it introduced its high-end coffee brand Levee in 2010.

In 2021, its engineering team started working on its first Levee espresso machine. However, being familiar with the coffee industry, the company knew that in order to get noticed by customers, any product would also need to stand out to baristas. So it turned to one of the world’s leading design studios with a history of style: Pininfarina.

“The goal was actually a triple goal,” says Nicola Girotti, head of ideation and industrial design at Pininfarina. “On one side, it was to design a beautiful machine; on the second side, it was to be visible in the market, where other players have been for many, many years, and have a very established position; and, thirdly, to create something that was really helping the position of the brand in this competitive arena.”

Hands-on research

The design process started exactly where it was going to end: a bar counter. Pininfarina brought its client Helvacıoglu Kahve to see how Italians consume their coffee, what baristas look for in a coffee machine and to identify gaps in the market.

“We were given a very specific brief in this case,” says Girotti. “The goal is to try to make something that is unique but also proven by the baristas to be the best machine in the market. So, we couldn’t just start from a simple layout and do a normal design job.”

Both Pininfarina and Helvacıoglu Kahve were very well aware that having an important name and coming up with a good design were not going to be enough to truly stand out from the crowd of big brands that dominate the industry.

To do so, they need a machine that gives them control over all these elements, while at the same time being intuitive, and offering a unique and distinctive design.

By interviewing different professionals, the design team had a chance to identify what control areas on the espresso machine the baristas interact with most, and how they manually control the levers, knobs and handles.

The human/machine interface (HMI) was essentially co-designed with baristas, says Girotti: “The job of the design and the job of developing the HMI were very much done in parallel. Every time that we were doing this evaluation with the baristas, we were actually fixing some points and putting some question marks on others.”

Barista-friendly HMI

“First, we created a very low-fidelity prototype directly with the customer, in order to engage them and initiate our thoughts on the overall HMI,” he explains.

“We decided on purpose to go very manual or very digital, to try to have a range of different interfaces with different HMIs, and then we selected three of them and we prototyped them with 3D-printed elements.”

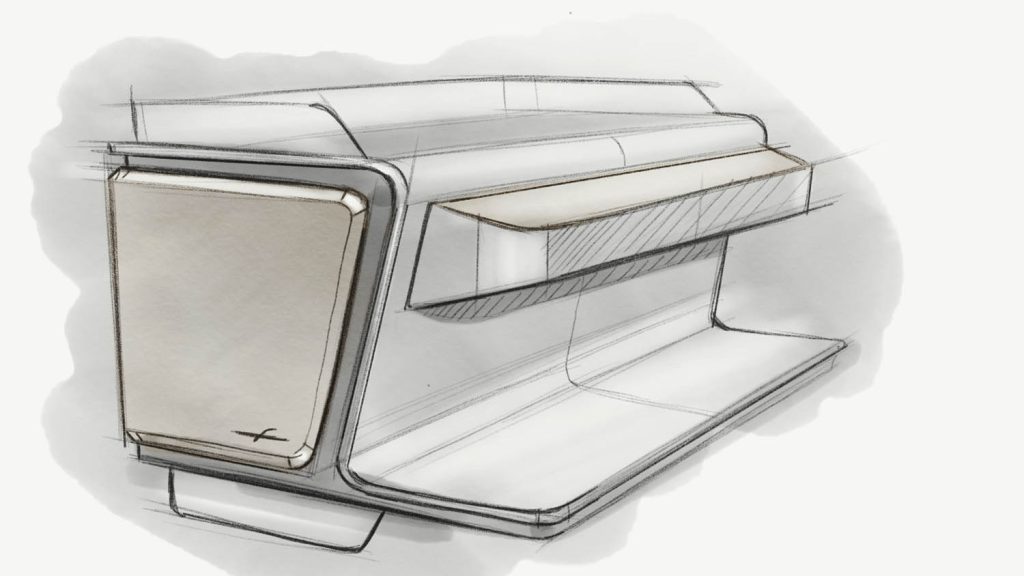

The first prototypes were rough and experimental, using foam and card, and then glueing on different elements, before the design team split into groups to focus on identifying different solutions and variants.

During this hands-on research, the team identified three clusters of baristas, all with specific needs and demands.

“What we did was a role play; we were not designing the best interface for us, but the best interface for each specific cluster,” Girotti explains.

“[We were] trying to see the different kinds of configuration because, with the end result, you want to be able to stretch and support all targets.”

The whole HMI for the Levee machine was designed to provide baristas with a pleasing as well as functional tool to use. The design team studied ways to give them visual and tactile feedback while they are using it, to help them feel a connection with the product.

“From the display to the buttons on the top, we wanted to make something that felt alive,” says Girotti.

Right knowledge, right tools

The Pininfarina design team had many tools and resources to draw from, starting from a fully stocked model shop, which proved useful in the first stages of the design process, as well as mixed reality technologies for visualisation, and a selection of CAD software tools to choose from.

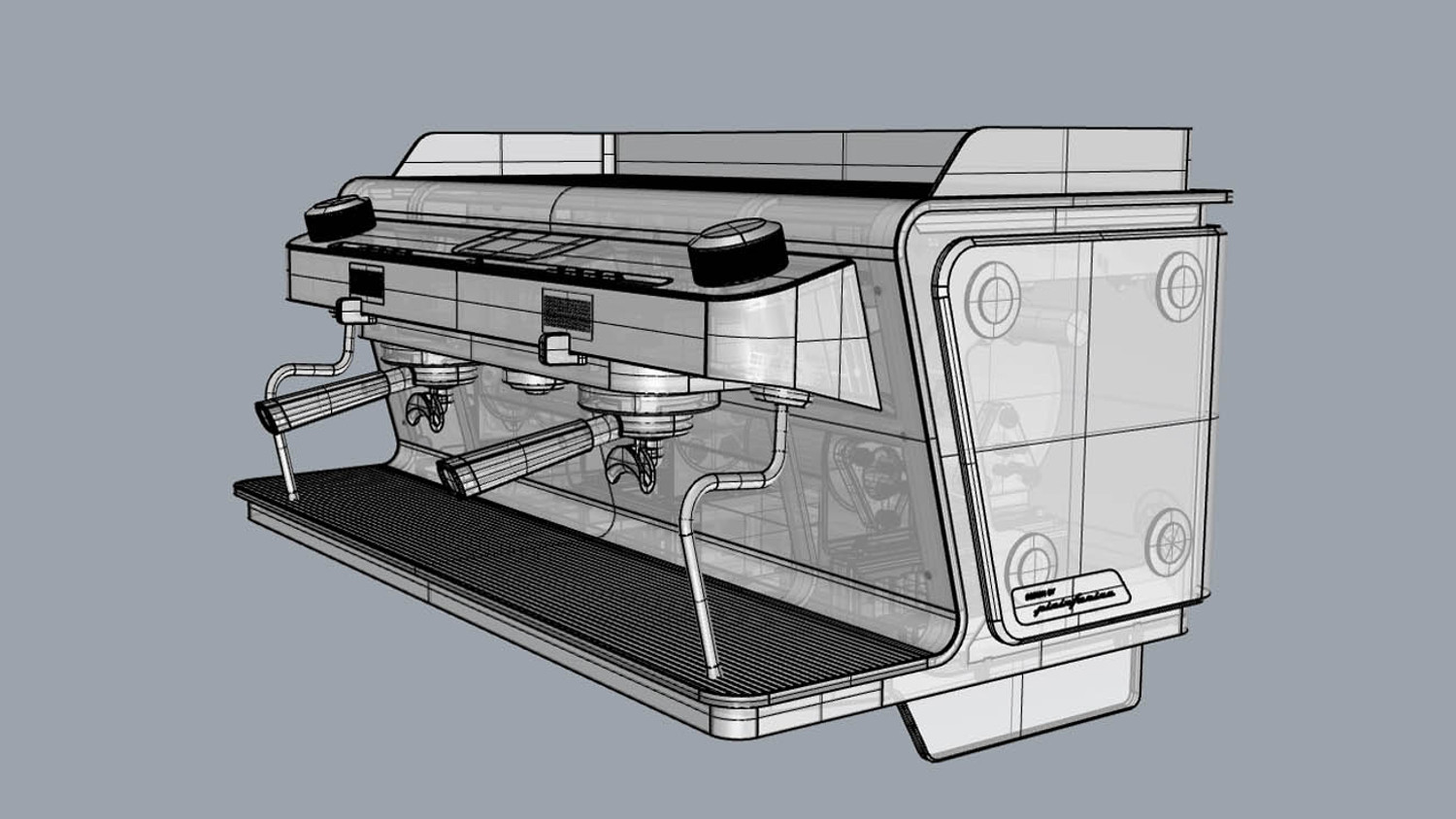

To design the initial form of the machine, the design team worked in Rhino to quickly generate the shapes and layout of key features. Says Girotti: “Once we had a good idea of what was the final design, from that moment we then moved to Creo, because we wanted to create volumes and surfaces that were very precise.”

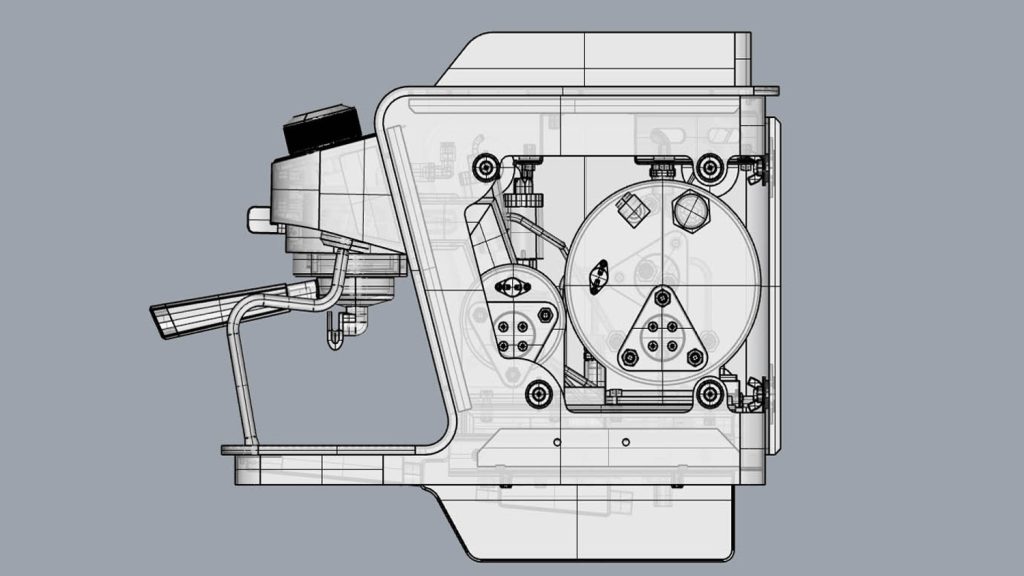

The engineering team at Helvacıoglu Kahve had already designed the key internal workings of the espresso machine using Solidworks, helping it develop a pressure system that enabled smooth and constant steam flow for more controllable use. Once Pininfarina had built a 3D concept design around this interior system in Rhino, it switched to PTC Creo in order to create the very precise volumes and shapes needed to transform the external structure and key touchpoints into a manufacturable form, while helping maintain original design intent.

“The beauty of having a multitude of tools, in my position where I’m leading the entire team, is that I can discuss with my team and say, ‘Why don’t we try this?’, and we try to propose it to the client at a very early stage,” says Girotti. “And they can have the perception of the physical object in all its beauty and proportion very early in the design phase.”

The choice of materials proved a turning point in the design process. To build the touchpoints that require skills and knowledge from the baristas, such as the handles and knobs, they chose to use wood, which not only gives a nice texture to the touch, but also ages well and can be matched to an existing environment.

Plus, wooden elements help protect the user from high temperatures. Anyone who has ever used an espresso machine knows how unpleasant it is to burn yourself while making a cappuccino.

“The other element where we put wood, for example, is the little lever on the front. This is for professional baristas: they don’t press a button, they use this lever for controlling the exact time of pre-brew and brew, in order to extract the best aroma from the coffee,” says Girotti, explaining that the reason they selected wood over other materials goes beyond just its physical properties. “Everything that is an interface, is also connected with something that is very warm and human.”

Levee // Smooth, sophisticated design

A digital control panel on top of the machine allows baristas to receive information regarding temperature and brewing time and features a set of buttons that allows them to use the machine in an automatic mode. This way, the machine is accessible to baristas with different levels of expertise and in different contexts.

Every element has been designed keeping in mind the aesthetics as well as the practicality, explains Girotti. For example, there are few edges to trap coffee grinds, because the machines need to be easy to clean daily.

To facilitate that even further, Pininfarina introduced two glass platforms at the bottom of the machine, raising the machine above the counter: “It is beautiful because it looks like the machine is suspended. But on the other side, we learnt that it is fundamental to have at least four centimetres [of clearance], in order to clean underneath the machine on a daily basis. We’ve been learning what the relevant things are to the end customer, and we implemented them in a design that is very iconic.”

Girotti says most coffee machines are made of bent sheet metal and other pretty cheap materials, which isn’t reflected by the six-figure prices, which are typically added to justify a big-name brand.

“From a production point of view, they are not worth €10,000. It’s just the brand that’s pushing the price,” says Girotti. “We needed to go into that world, but with something that was clearly different.”

The approach Pininfarina adopted was to develop a machine with a seamless, high-end finish. All nonrelevant elements such as screws and mechanical parts are hidden from view. Yet given this is a professional machine, access for maintenance is still a high priority, so the design team created a system of magnets that attach key cover panels, which look sophisticated to the eye and yet are easy to unlock when necessary.

“The lateral panels, for example, we fixed them with magnets – the same magnets that we use in Formula One cars,” explains Girotti, referencing Pininfarina’s decades of experience in automotive design. “We are maintaining the simplicity of use, but also offering a sophisticated design and solution.”

Levee // Great espresso in any location

Another feature of the Levee coffee machine is its versatility, adapting to different locations as well as to different users.

The wooden elements come in different grains and natural shades, and can be matched with a café or restaurant interior. There is an option to choose between a one-group and a two-group serving coffee machine: “If you want to enter into a bar, you need to be able to make four coffees in one shot. It’s a question of time,” explains Girotti.

“With the one-group machine, we can enter other kinds of businesses, where maybe you don’t need to produce as much coffee as you do in a bar: a hotel for example, or a restaurant, or the home of someone who wants something unique – or even on a yacht,” he says.

“A lot of machines put all the effort on the front and then the back is like just metal with a grid. We decided to design a machine by looking at it from 360-degrees, with wood and a backlit logo at the back.”

In essence, Pininfarina wanted the Levee machine to be a piece of interior décor, that could immediately and forcefully communicate its high level of quality and sophistication.

“There is quite an intimate connection between the barista and the machine, because they use it on a daily basis – eight, nine, even 10 hours a day. They can tell you a lot of stories,” concludes Girotti.

And great stories make for great designs. The new Levee espresso machine seems to have what it takes to conquer a market where brewing good coffee is simply not enough. Through its sophisticated lines and honed interface, it aims to support baristas in their mission to bless us all with a daily cup of tradition.