The world of sports aircraft has a versatile new star flying in from Sweden; one that can take off from land, set down on water, and perform dizzying acrobatics.

The LN-3 Seagull is a high-winged amphibian small aircraft with two seats in tandem and an engine in a pusher configuration on top of the cabin.

The rear-mounted propeller pushes rather than pulls the plane through the air

The retractable landing gear, located in a wing-shaped pod at the lower part of the fuselage, is completely submerged when the Seagull is floating on water, acting as a stabilising float.

Most impressive though is its versatile standing across the many different regulations for small aircraft and the various classes and licenses. To date it covers six different classes in Europe and the USA, and this is made possible through its clever design and production using composite materials.

A family affair

The design and engineering team is very much a small-scale family affair. The LN-3 Seagull took shape in aerospace engineer Lage Norberg’s mind early in the 1980s. With a passion for fly fishing, he dreamed of a small amphibious plane to take him between the Swedish lakes.

Eventually Lage’s sons, Tomas and Staffan, joined the team in 2004 and the Seagull began to take shape in their hometown of Sundsvall, Sweden.

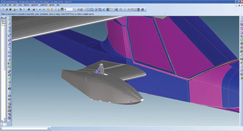

Having set up the company’s base ‘Flygfabriken’ – Flying Factory – on the outskirts of the city, the team set about working with PTC’s CoCreate software to build an accurate 3D model for making clinical adjustments to the original prototype.

Precision engineering

Working in composites and having to meet strict size and weight dimensions meant that the design had to be precisely modelled to ensure all criteria were met.

“The possibility to calculate volumes and weights of all parts is a great advantage when calculating precise location of centre of gravity, which of course is very important when designing an airplane,” says Staffan Norberg.

Staffan explains that being able to use a CAD system that was able to import previous designs from various other CAD packages was key to them working in CoCreate.

“We really liked the idea of a fully dynamic 3D CAD system so we started out testing the Modelling Personal Edition,” says Staffan. “We have a lot of experience with history-based 3D CAD software and immediately saw many advantages with explicit modelling.

“During development it’s been a tremendous advantage to be able to design and redesign without considering how the part or assembly was built up originally.

“We have also been able to pick up parts from other systems and start working with them as if they were native CoCreate parts.”

It’s been a long time in production, but by working with the software the team is convinced that the design and prototyping process has sped up, with the production of moulds arriving quicker, and two new team members brought in to help with the manual fabrication.

“We find it very dynamic and it’s an easy way to work in a CAD system and it has, for sure, shortened the design time for us,” says Staffan as he gives a tour of the workshop floor.

The flying factory

The plane is currently in parts as a redesign of the wing position and landing gear sees the team designing new landing gear pods, making adjustments to the original CAD model before CNC machining a new mould from the CAD data.

On site the pre-epoxy impregnated carbon fibre weave is cut to size, and two large ovens are able to cure the composites into forming the parts.

In keeping the product as Swedish as possible, local engineering firms help produce tooling and parts in aluminium, with the design team sending them the CAD data to be made into moulds for the intricate carbon fibre support rods.

This may seem like a lengthy process, but once it comes into full production all the parts will have been accurately tested and produced from moulds that correspond directly with the 3D CAD model. This helps produce a finished aircraft both accurately and quickly.

Getting ready for take off

The plan is to sell the LN-3 Seagull as a fully functioning craft, or make it available in kit form. Until then, the short-term goal is to have all the final adjustments made to the prototype so that it can impress potential customers.

With the final adjustments made to the prototype it should easily impress potential customers

With both seats aligned along the major axis the plane has excellent balance, even with only one person on board. The ability to land pretty much where you please makes it ideal for those without a local runway, and because of its weight, speed and manoeuvrability, it is fun to fly. Furthermore it has a unique capability.

“It is the only amphibious plane cleared to do aerobatics in the world that we know of,” says Lage proudly.

The rear-mounted propeller leaves an unobstructed view from the front of the aircraft, much like a glider, pushing rather than pulling the plane through the air into twists and turns.

“The key to success is to endure the long journey of development and to present presumptive customers a product that is reasonably ready to be used by anyone,” says Lage.

“There are many signs telling us that the Seagull potential is enormous and the worldwide market is huge.”

www.flygfabriken.com

With the help of CoCreate, the LN-3 Seagull can do things other planes can’t