Last summer, in a Harvard University robotics laboratory, an insect took flight.

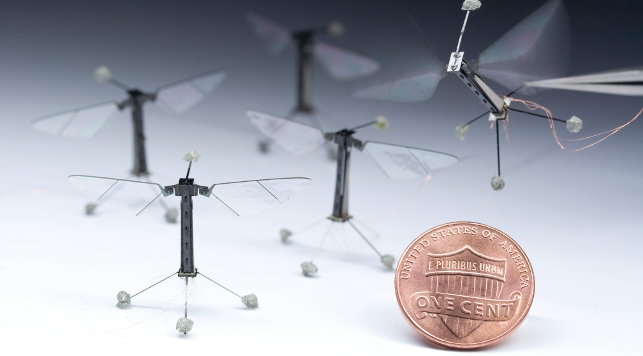

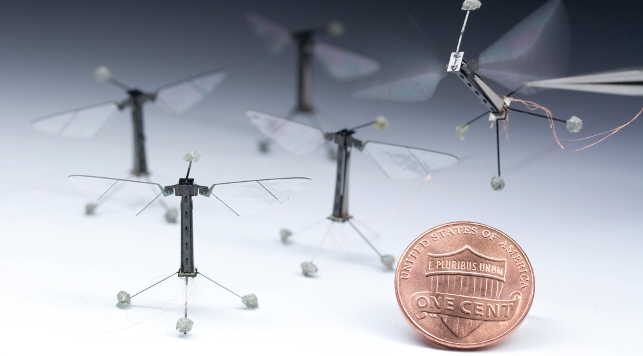

Robotic insects the size of an American one cent coin

Half the size of a paper clip, weighing less than a tenth of a gram, it leapt a few inches, hovered for a moment on fragile, flapping wings, and then sped along a preset route through the air.

Like a proud parent watching a child take its first steps, graduate student Pakpong Chirarattananon immediately captured a video of the fledgling and emailed it to his adviser and colleagues at 3am – subject line: “Flight of the RoboBee”.

The demonstration of the first controlled flight of an insect-sized robot follows more than ten year’s work, led by researchers at the Harvard School of Engineering and Applied Sciences (SEAS) and the Wyss Institute for Biologically Inspired Engineering at Harvard.

“This is what I have been trying to do for literally the last 12 years,” says Robert J. Wood, Charles River Professor of Engineering and Applied Sciences at SEAS, Wyss core faculty member, and principal investigator of the National Science Foundation-supported RoboBee project.

“It’s really only because of this lab’s recent breakthroughs in manufacturing, materials, and design that we have even been able to try this. And it just worked, spectacularly well.”

Science imitating nature

Inspired by the biology of a fly, with submillimetre-scale anatomy and two waferthin wings that flap almost invisibly, 120 times per second, the tiny device not only represents the absolute cutting edge of micromanufacturing and control systems, but is an aspiration that has impelled innovation in these fields by dozens of researchers across Harvard for years.

“We had to develop solutions from scratch, for everything,” explains Wood. “We would get one component working, but when we moved onto the next, five new problems would arise. It was a moving target.”

Flight muscles, for instance, don’t come prepackaged for robots the size of a fingertip. “Large robots can run on electromagnetic motors, but at this small scale you have to come up with an alternative, and there wasn’t one,” comments Kevin Y. Ma, a graduate student at SEAS.

The tiny robot flaps its wings with piezoelectric actuators – strips of ceramic that expand and contract when an electric field is applied.

Thin hinges of plastic embedded within the carbon fibre body frame serve as joints, and a delicately balanced control system commands the rotational motions in the flapping-wing robot, with each wing controlled independently in real time.

At tiny scales, small changes in airflow can have an outsized effect on flight dynamics, and the control system has to react that much faster to remain stable.

Pop-up manufacturing

The robotic insects also take advantage of an ingenious pop-up manufacturing technique that was developed by Wood’s team in 2011.

Sheets of various laser-cut materials are layered and sandwiched together into a thin, flat plate that folds up much like a child’s popup book into the complete electromechanical structure.

This step-by-step process is very quick and replaces what used to be a painstaking manual art and allows Wood and his team to use more robust materials in new combinations, while improving the overall precision of each device.

“We can now very rapidly build reliable prototypes, which allows us to be more aggressive in how we test them,” says Ma, adding that the team has gone through 20 prototypes in just the past six months.

Applications of the RoboBee project could include distributed environmental monitoring, search-and-rescue operations, or assistance with crop pollination, but the materials, fabrication techniques, and components that emerge along the way might prove to be even more significant.

For example, the pop-up manufacturing process could enable a new class of complex medical devices. Harvard’s Office of Technology Development, in collaboration with Harvard SEAS and the Wyss Institute, is already in the process of commercialising some of the underlying technologies.

“Harnessing biology to solve real-world problems is what the Wyss Institute is all about,” says Wyss Founding Director Don Ingber. “This work is a beautiful example of how bringing together scientists and engineers from multiple disciplines to carry out research inspired by nature and focused on translation can lead to major technical breakthroughs.”

The project continues

The prototypes are still tethered by a very thin power cable because there are no off-theshelf solutions for energy storage that are small enough to be mounted on the robot’s body.

High-energy-density fuel cells must be developed before the RoboBees will be able to fly with much independence.

Control, too, is still wired in from a separate computer, though the team is working on a computationally efficient brain that can be mounted on the robot’s frame.

“I want to create something the world has never seen before,” says Ma. “It’s about the excitement of pushing the limits of what we think we can do, the limits of human ingenuity.”

Harvard University scientists create a tiny flying robot modelled on a fly

Default