In a nation known for its extreme sports and active pursuits, one can’t imagine the average New Zealand parent toning down his or her lifestyle for something as routine as raising a child. While few adults are likely to fling themselves off bridges attached to little more than their six-month old child and a bungee rope, many are looking for ways to maintain their vigorous routines while turning to products that can adapt to the family’s growing needs.

With fanfair New Zealand product design firm phil&teds has launched the sub4, a pushchair taken to new heights, transforming an everyday child carrier into a functional jogger. The usual factors of infant comfort and safety were high on the list of priorities, but a lot of attention was also paid to making sure the design fits into an active adult’s lifestyle.

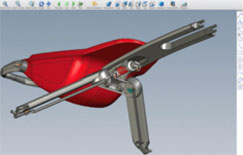

Modo render of the sub4 jogging stroller

“The sub4 was created with the view that sports-minded, athletic, bike-riding parents who love to run would actually like to be able to run with their strollers,” says founder Phil Brace, who continues to lead the design team for the pushchairs and strollers that form a key part of the baby products it produces. “The sub4 needed to look ‘fast’, be able to corner ‘fast’, stop ‘fast’, fold ‘fast’ and small, and most of all be cool, and leverage the fast moving cycle industry. The sub4 is like the mountain bike in the cycle world.”

With 25 years’ experience in product design, Phil has continued to “put one foot in front of the other” in order to live out his design dream of getting new products like the sub4 out into the wider world.

Concept sketch of the seat and spring mounts

SolidWorks model of the seat and mounts

Formed in 1995, phil&teds is based in Newtown, New Zealand where Phil heads a design team of 20. “It’s secretly quite a large development team for little old NZ – I’m a designer, and a leader, so I try and lead by example, compete to have the best ideas, and most of all have fun!”

“I am pretty old school when it comes to creativity and development,” laughs Phil. “My business card says: ‘imagination to reality’.

The sub4 jogging stroller has some interesting design features such as the low- resistance wheels and dual rear disc brakes. It can be controlled with just one hand, manoeuvres easily and is perfect for some serious jogging.

By calculating the ideal biomechanics of someone jogging whilst in control of the pushchair, adjustments could be made so that it could turn corners safely, remain completely stable at high speeds, be stopped safely using only one hand (and the large mountain bike style disc brakes) and still allow full stride lengths.

For the seat the design process already had some basis in that some moulded protective breastplates for female athletes were benchmarked against a seating concept from a kids bike.

“The goal for us is to increase speed, reduce risk, and innovate in our own market – a moulded seat that is waterproof, hypo-allergenic, easy-clean, soft where it needs to be soft, hard where it needs to be hard, offered lots of opportunity for design – but in this case we just had to tool it up to really know.”

This is not to say that computer-aided design doesn’t play a big part in what phil&teds produces.

“It all starts as an idea, gets refined on a sketchpad, then proven in the workshop. After that, we visualise on screen before committing to the likes of the engineering tools for implementation.

“I’m not such a fan of CAD development without first engaging the brain.”

These days phil&teds works primarily with SolidWorks and Modo to build its conceptual models, working with the idea that, deep down, they know what is best from the start.

“I am a firm believer that you know in your heart the right path to take – mostly if you second guess this, all you do is consume time with another idea, and it is seldom a better idea!

“These days virtual imaging is the norm to communicate and excite the team, while physical prototyping is there to prove the idea pre-tooling.”

“For implementation SolidWorks is the tool of choice for the design and engineering team,” continues Phil. “We’re not designing space-shuttles just yet, so SolidWorks is perfect for plastic parts, extrusions, and the mechanics of folding mechanisms.

“Modo provides the pre-design visuals, and later the accurate renders from the SolidWorks data. I still use VMRL exports from SolidWorks via blender to LWO and then to Modo – crazy but easy to control the polys.”

Virtual imaging is the norm to communicate and excite the team, while physical prototyping is there to prove the idea

Phil Brace, founder, phil&teds

Phil is a self-confessed amateur rendering addict, a skill that with ten years of honing has proved a useful asset when it comes to getting products to market.

“My job as a designer is actually a sales role – reality is everything. So as the cost of prototyping increases it’s great to balance this with a good dose of CG to do the job!

“I like to have the tools in-house, I like the team to have the satisfaction, and the personal achievement in getting the product to the market – we are relentless about speed to market, so we need the tools at hand – last week I even converted three old raid servers to Modo for network rendering!

“Modo is precise down to the micron, but has the dual benefit of both hard and soft modelling – to be fair we used to favour Rhino for our ‘ID’ work, but these days Modo formeisthetoolofchoice-Ididmyvery first animation rig for the sub4 in Modo, so even the benefits of SolidWorks with its ‘kinematics’ is dropping off for me as an industrial designer.”

Seeing the sub4 in animation leads to thoughts of it in action – an ideal piece of design for the modern lifestyle where nothing slows you down.

www.philandteds.com / www.luxology.com

phil&teds use a blend of CAD and visualisation to create its pushchair for active parents