Earlier on you’ll have read about some of the more recent advances in desktop or workshop-level CNC machines. As we point out, there’s never been a better time if you’re looking at bringing something along these lines into your in-house workflow.

But if you’re looking at this type of machine, then you may very quickly realise you also need a 3-axis CAM solution.

Take, for example, DEVELOP3D’s own experiences with the Inventable X-Carve machine we’ve built in our workshop. While the X-Carve is supplied with access to Inventable’s own 2.5D CAM application (called Easel), this is a vector-based system that’s really only useful for more simple forms and basic routing projects.

That won’t really serve the more complex needs of many design and engineering houses – but fortunately, the rise of more affordable CNCs has been accompanied by a corresponding growth in similarly cost-effective CAM systems that enable you to bring in CAD geometry and generate tool paths that will machine the components and prototypes that you need.

Controller support

The CNC machine market is a curious one when it comes to standards.

They get adapted over time and, while it’s true that all machines run on G-code, there’s a big range of variants out there, mostly dictated by the controller running your CNC machine.

In effect, controllers act as the gateway between your CAM system and your CNC machine. They take the G-code from your CAM system and translate it into the movements that various parts of the machine need to make, such as the speed of the spindle and so on.

At the entry level, controllers are most commonly driven using an Arduino-based solution called GRBL. If you’re diving into this, then you do need to ensure that the tools you’re using to programme your CNC are compatible with your controller.

Special features

There’s a lot variability at the entry level in terms of what can and can’t be done. For example, in higher-end machines, it’s common for spindle speed to be controllable.

That’s not the case at the entry level, however, where spindle speed tends to be pre-set and remains constant throughout the job.

Another commonly unsupported feature is depth probing. While it’s a standard feature on most pro-level CNCs, many desktop CNCs lack it (with some notable exceptions, including the Othermill and Nomad machines).

It’s pretty easy to connect up a probe, but you also need to make sure that your software/hardware combination supports it properly.

Workflow

While compatibility and controllers are key, another thing to consider is your own workflow. In other words, what kinds of shapes and materials are you going to be cutting?

If they’re basic forms, then a simple CAM solution will work. But if you’re looking to machine more complex forms, they’ll require 3D machining.

Are you looking, for example, to machine foam models to represent the exterior of your product? Are you proving out toolpaths for bigger, machines to handle? And what about two-sided machining?

Having a CAM system that makes light work of the tasks you’re looking to get done is essential (something like MeshCAM, described below, supports all of these use cases).

Cost effective CAM for the workshop CNC

Looking for some cheap CAM for your CNC machine? You could do a lot worse than consider these three options

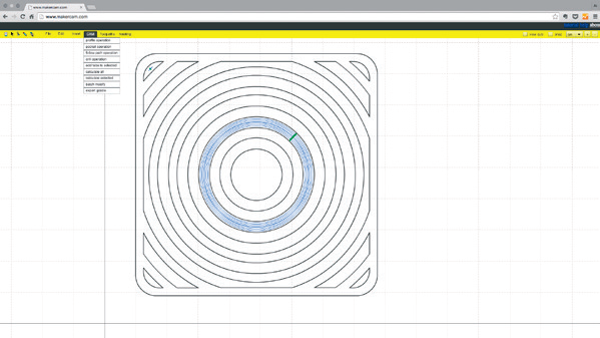

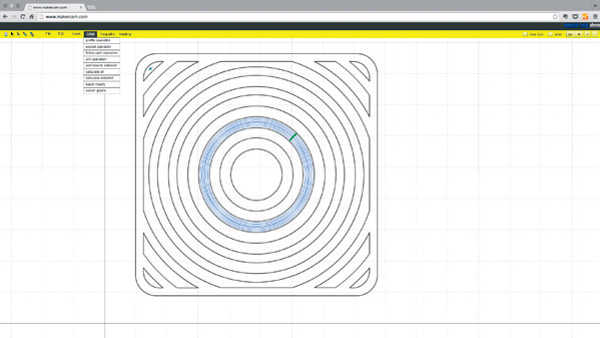

MakerCAM

MakerCAM is an entirely browser-based CAM system, focussing on 2.5 axis CNC jobs. It allows you to either upload an SVG or sketch the geometry directly, then generate the cutting toolpaths you need. It’s pretty basic in terms of complexity, but there are some nice tools for nesting there. It’s also free.

makercam.com

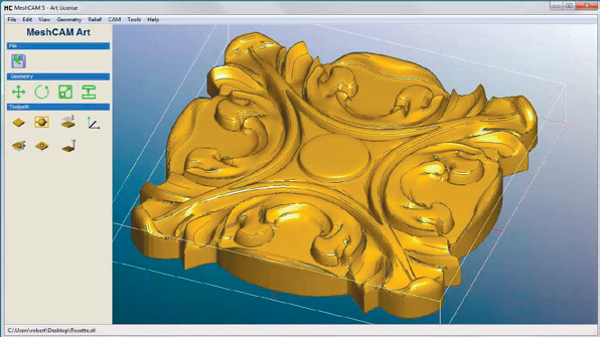

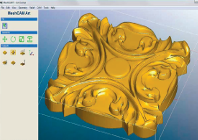

MeshCAM

MeshCAM is built for the process of machining meshes (in other words, STL data). It’s cheap and it includes tools that will make machining two-sided (or more) projects much quicker. The toolpaths won’t be the most efficient, but automation of twosided jobs will make up for it. It costs $250 or $500 for a Pro version that adds simulation to the mix.

grzsoftware.com

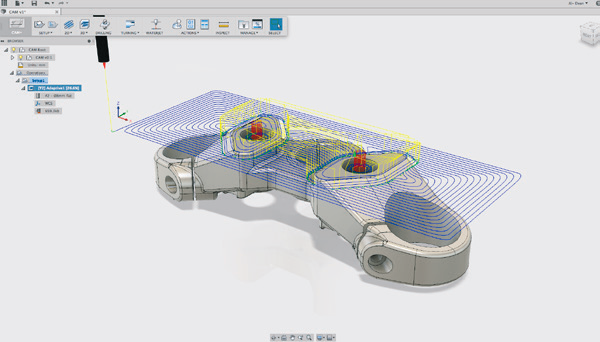

Fusion 360

Fusion 360 doesn’t really need any introduction to DEVELOP3D readers, but its CAM capabilities will be of interest to many looking at CNC for the workshop.

It covers everything from basic 2D machining, through 3 axis and into 3+2, with full toolpath simulation and an extensive list of posts for all manner of machines – all for $25 a month.

autodesk.com

A look at what’s available and the purchase considerations to bear in mind

Default