A stylish collection of door furniture, Sweet, has been launched by the Brisant Secure brand for those seeking an alternative to the traditional designs on the market.

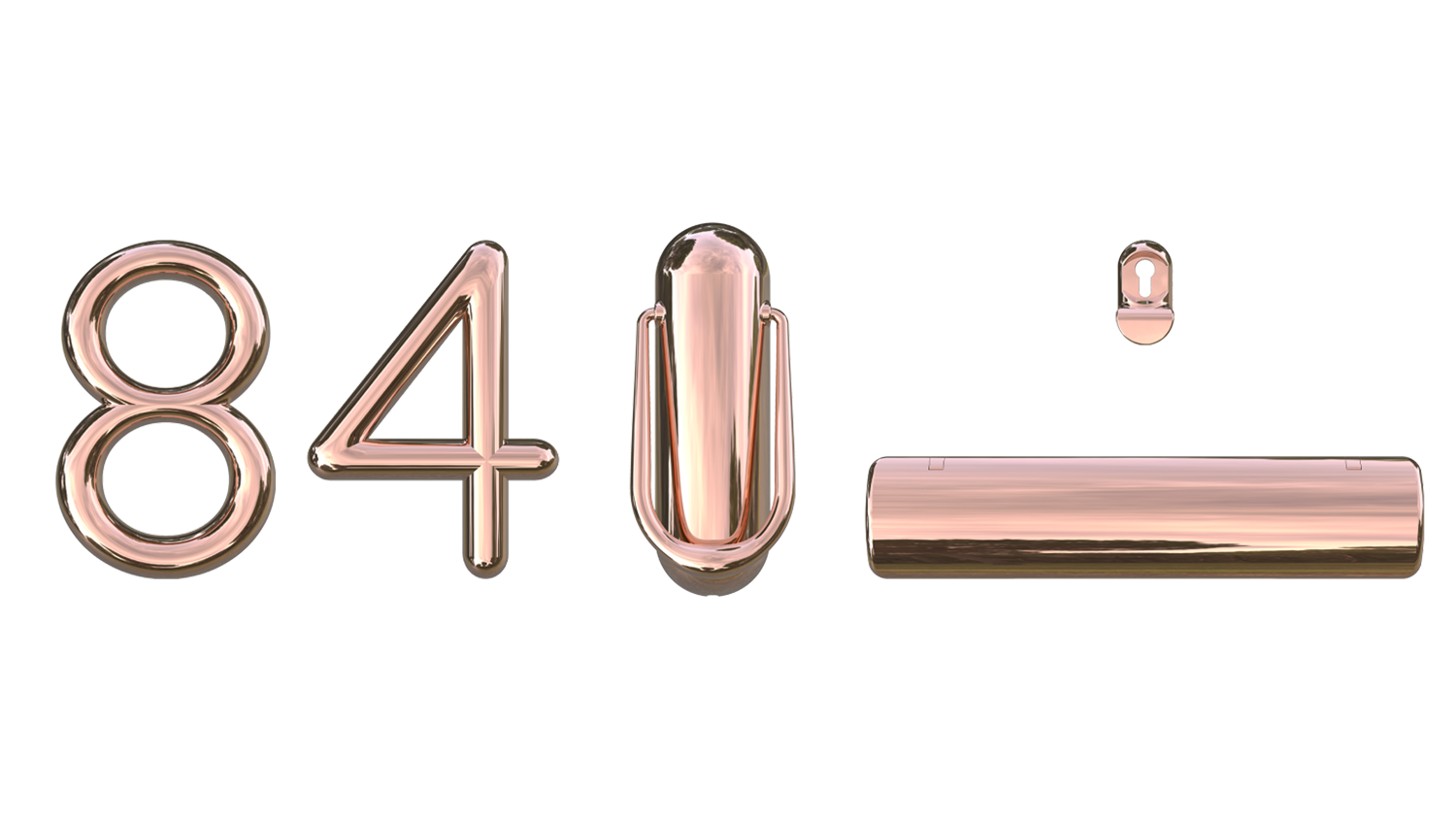

Sweet has a luxurious collection of products – door handles, letterboxes, numerals and door knockers – in a wide range of finishes that can match the homeowner’s personal style, just as any other item in the house.

However, the ethos behind Sweet is not simply decoration – the parts offer practicality, functionality, and durability.

Brisant’s first foray into the world of door furniture and accessories was through the development of its Ultion lock: a robust door lock backed by locksmiths nationwide and even the police.

Through its work on the Ultion lock, the design team spent time looking at and analysing the nation’s front doors, and noticed a distinct lack of diversity when it comes to door furniture.

“We all know kerb appeal counts; but so many homeowners in the country were settling for rusted or old fashioned door-furniture that didn’t suit their home or their style,” says Brisant director Nick Dutton.

Yet the unique edgeless design is paramount to the Sweet range for more than just looks.

“Thanks to our extensive knowledge and expertise within the security industry, we know just how easy it is for burglars to break in.

“The curved shape of our products – in particular the handle – leave no surface area for a potential intruder to grab onto with pliers, or any other tool, thus providing a home with added protection.”

“My business partner and I have decades of experience within the security industry; so we took this knowledge of what makes a home or front door safe and applied it to door furniture – a move that hadn’t yet been done by other brands,” says Dutton.

“We also wanted to marry design with practicality, and create something that looked contemporary; a sleek and stylish alternative to many of the traditional designs on the market right now.”

After several rounds of sketches, Brisant’s designers settled on a streamlined design theme across the product line – from door numbers, to the letterbox flap and unique door knocker.

There was a concern over the design that the curved shape would reduce the internal area of the product on the reverse for fixing the product to the door.

SolidWorks was used to being the concepts into 3D CAD, which meant 3D printed and CNC machined prototypes could be produced and any concerns about internal space could be worked out.

“This helped us to achieve the same exact dimensions throughout the process, ensuring uniformity across all products in the range,” says Dutton.

Customers have a choice of colourways – timeless gold, chrome and white finishes plus more modern finishes such as gloss black, matte graphite and a new rose gold finish.

Multiple metal coatings ensure it maintains its aesthetic – even after being hammered with saltwater for over 8,000 hours!

“Our hardware lasts an astonishing 30 times longer than average industry standard,” claims Dutton. “So confident are we in the product that we offer a 10 year guarantee.”