Kara Black talks to students at Concordia University in Montreal solve a specific design challenge with the help of Geomagic Studio and the Creaform Scanner

Named after the black panther from Rudyard Kipling’s The Jungle Book, the Bageera is the powerful entrant from student Rambod Radmard and his teammates into Montreal’s Concordia University annual design competition.

The Bageera

Entitled the Capstone Design Project, final year undergraduate engineering students solve a specific design challenge of their choosing. Rambod and his team chose to create a hybrid of a Volkswagen Jetta and a Yamaha motorcycle.

“We wanted to do something that stood out,” exclaims Radmard. “We wanted to do more than the other teams from previous years’ Capstone projects. We really liked our university’s Formula SAE race car and were inspired by it to make a two-seater roadster version, intended for thrill rides, as our final year project. “In my years of studying at Concordia, I don’t think that I’ve seen a project of this scale being done by undergraduate students before.”

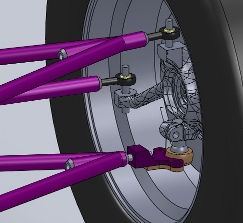

“Our project is building a car where we’re designing the frame and we’re designing the suspension for it,” says Rambod. “It’s not going to do anything unless you have components like an engine, wheels, seats and even a steering wheel in it. All these things have to be there to have a functional car.

That’s where the whole scanning and using Geomagic Studio to use the scan came into play.” One of the main obstacles Rambod and his teammates tackled was one of part integration. “When you use an old part from an old system, designed to work with that system, and you try to adopt it to a new design, the compatibility becomes an issue,” says Rambod.

“Having a gearbox from a full sized car allows us to have a heavier gear ratio because the engine from the motorbike wasn’t designed for a vehicle that has a weight like our car has. That’s why we needed the new gearbox, and the benefit of having a front wheel drive gearbox is that it has an integrated differential that spreads the power to the wheels through the drive axles. Everything was there already. To do this we needed to know how all these things looked like.

“Theoretically this all sounds good, but once you actually want to design these parts to work together, you need to know how they look like exactly. That’s why we had to scan these critical parts.”

Scans were created using a Creaform scanner, and placed through Geomagic Studio to be turned into usable 3D. The data was then placed into SolidWorks.

“One cool thing about having these parts in SolidWorks is, for example, once we designed the geometry of the suspension, the wheel hubs needed to be modified to reflect our new geometries instead of those of the vehicle they were designed for; because we had a 3D replica of the hubs in SolidWorks, we were able to modify the 3D models to the exact geometries we needed. This allowed us to test the modified hubs first and see how all the new components will work together dynamically.

“After we were satisfied with the modifications that had to be done on the hubs, we took them to the machine shop, machined them and assembled them, and all the geometries turned out the way we designed them to be.”

Even though the frame was made from mild steel, a low carbon versatile metal that along with other purchased parts cost only $2,000, and the engine came from a Yamaha FZR 600, Rambod does not want to push the vehicle past its full potential. “I don’t think we want to test the limit of how fast it can go, but based on its design, it can go over 100km an hour.

“For safety reasons, I don’t think we want to go that high. At the end of the day, it doesn’t have an airbag; actually, other than seatbelts, it doesn’t have any of the conventional safety features that we’re used to, like ABS brakes, but the frame itself is really really well designed! We’ve tested it using impact simulations, and all kinds of other different loading scenarios in SolidWorks, just to know that passengers are going to be safe.”

Having teammates that were friends lent itself to a more successful result. “It helps that our team was a group of close friends, and we all decided to do this together. Other teams, who didn’t propose their own projects, didn’t have a choice in their team members.

“People would go a little bit further, the extra mile. At the same time, it is harder to tell people what to do.

“If you have all your friends working on it, it doesn’t feel like work anymore. It’s fun. It really became a hobby almost.”

Rambod and his teammates gained a good deal of insight as a result of the experience. “It was the biggest project I have ever done, and it did teach me a lot about myself. I now think everything is do-able, if, you spend enough time and resources on it.

Even though the final version of the Bageera has not been submitted for a grade yet Rambod is hopeful that it will adequately reflect the team’s hard work and the invaluableness of the technology they had to work with.

The Bageera – a powerful entrant at Concordia University annual design competition – discovers Kara Black

No