Writing about design technology for the last fifteen years has brought me into contact with a huge range of people, technologies and organisations. One of the rare privileges has been seeing companies

start up, grow and become successful.

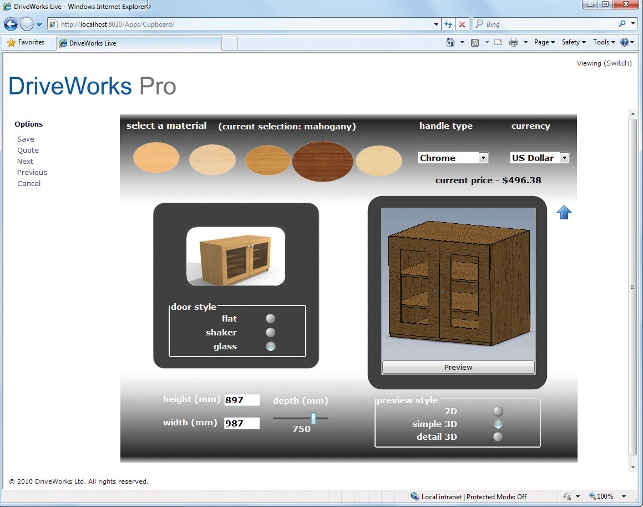

Configuring and costing a cupboard online using DriveWorks

DriveWorks is a prime example of such a company. It develops software that assists in automating product design based on a set of rules, either at a local workstation level, or wider scale across an enterprise.

My first encounter with Glen Smith, DriveWorks’ CEO, was back in the late nineties. In a room just off the factory floor at a customer site, he was demonstrating a custom built rules-based system for the

design of utility vehicles.

It was while cutting his teeth on customer automation projects at a SolidWorks VAR that Smith discovered that his engineering background, combined with new found technical expertise, brought him some interesting skills and a new way of thinking about automation.

Historically, companies looking to formalise knowledge of their process or product in a single system relied on systems that were typically tightly integrated into, if not inseparable from, the host software.

This made editing and adaptation almost impossible unless you hired a costly consultant.

While carrying out such work, Smith realised that the key was to separate the host system (which carries out the automation) from the data that drives it. This is something he picked up on when I visited

the team in its corporate headquarters in Thelwall, Cheshire last month, and which goes back to the company’s roots.

“We started with custom code,” explains Smith. “There were a few companies at the time that wanted a custom configurator, or to do some design automation, but there wasn’t really anything on the market – it was all done using macros. That’s how I started with the reseller. It then progressed from doing macros to actual programs.”

Doing things differently

Having worked on a number of live projects it was not long before Smith realised the limitations of a completely bespoke approach to design automation. “When you’re doing custom programming, it’s very easy not to meet customers’ expectations,” says Smith. “The problem is that you and the customer don’t know what’s involved until you start delivering and jobs always overrun.

Back then, it became very evident that there was a difference between system and data. The customer had his knowledge about the product which formed the data and we could create a system but, more often than not, the two became one – we were hard coding their data.”

It was this realisation that led to the creation of the DriveWorks (the system and company) which was set up by Smith and vice president, Maria Sarkar in 2001. “When we did all of the early work we decided to differentiate the system from the data so customers could add their own fresh data and keep the system running,” he says.

“When you do that, the system becomes completely different because you need the ability for the customer to enter their own data in a user friendly way – rather than just dumping it in a database, in files, or even worse, dumping it in the code.”

The importance of SolidWorks

A driving factor behind the success of DriveWorks was the decision to build on top of SolidWorks, one of the industry’s leading 3D product development tools.

Working with the system DriveWorks was able to implement its modular approach. “That separation of the system and data adds a lot more to the system because it needs to be generic,” explains Smith. “That then becomes paramount if you’re going to take it to another company with a completely different set of data.”

In addition to the technology, the way SolidWorks is sold, through an indirect channel of resellers, was also of great interest to DriveWorks. “Maria and I decided that seemed like a very good market opportunity and it gave us a lot of opportunities,” says Smith. “Because we are building a generic application, it meant we could sell through SolidWorks’ existing resellers.

“It also meant we could focus on building the application and let the resellers and customers do the data. It also meant a wider audience. If you’re doing work specific to each customer, there’s obviously a limit to how many customers you could have – to grow the business, you’ve got to grow the staff.

“As we both know, if you just grow the staff, then the revenue doesn’t grow with it and the business does not scale. This is the basis of DriveWorks, to create the product, take it to market and see where we went.”

According to Smith, the first year was spent getting the product right, working with a handful of companies to fine-tune the application, get the business model right and start to make headway with resellers in the SolidWorks sales channel.

“When we started out, we knew the SolidWorks market very well and we always wanted to be the best in the world at something,” he recalls. “While over the years it’s been tempting to become multi-CAD, the sole focus on SolidWorks was definitely a good thing.”

Development decisions

Having seen the company grow over ten years, it’s clear that DriveWorks has been ahead of the curve in many respects – DriveWorks Pro was a web-based automation system or product configuration system way back before the term cloud became a hot-topic.

So how does DriveWorks define each generation of the product? Maria Sarkar picks this up, “We’ve always made a big point of listening to what companies want to be able to do. We go out and visit customers regularly and talk to them about what they want to do.

This gets fed back to the product development team, headed by Philip [Philip Stears, lead developer, DriveWorks], they assess all of the suggestions that come in, review the ideas from visits so we take the best from everywhere and incorporate them into our product.”

This is one of the most interesting things for a relatively small developer. By ensuring that all of the sales work is done through SolidWorks’ VAR channel, DriveWorks has managed to remain a software engineering team, something which Smith is both proud of and has been instrumental in.

“My background is in engineering, then I started writing software for engineers,” he says. “Maria is in sales and business to business marketing. Obviously now we’ve got a lot of developers on staff, but having the engineering and commercial input are vital to what we do.

“It’s not just something programmers have created thinking it would be a good thing for a particular market they know nothing about. We’re essentially a team that understands the needs of companies that design, manufacture and sell products.

We understand how engineers think and what they need to be able to create. Increasingly we go out of our way to understand their markets too and how they need to interact with their own customers, hence the adoption of our technology inside and outside their company.“

Global reach

DriveWorks’ customer base is now spread across the globe and growing each year, particularly since the inclusion of DriveWorksXpress within the core SolidWorks product and the more recent release of DriveWorks Solo. Both are designed to be self taught, backed up with online training resources and example projects that assist getting the user up to speed without much intervention.

With a global customer base, has the team seen any regional trends in how designers and engineers are approaching automation? Smith is quick to confirm the nature of the challenges that today’s manufacturing organisations face.

“I’m not sure there are regional trends, but there are trends across the board. There are a lot more global companies that have multiple sites, multiple languages, different time zones.”

The economy and automation

DriveWorks Solo was brought to market last year to help make the system much easier to use and learn and to help meet the changing market demands brought about by the econoapocalypse. So how has the team has seen its business change and what challenges have its customers faced since the beginning of the economic downturn?

“A really good indicator was that the interest in our products went up and sales of our products went up,” says Smith. “Companies faced with tough economic conditions really have two choices. They can lay off staff because there isn’t as much work. Then when things do pick up, they have to go on a recruitment drive and re-educate staff.

Or they can spend that time getting better at their jobs, so when things do pick up, they can come out of it quicker and stronger.” “There have been many companies that have sat back and thought ‘OK, I don’t want to lose my best engineers, what can I do to improve the situation?’

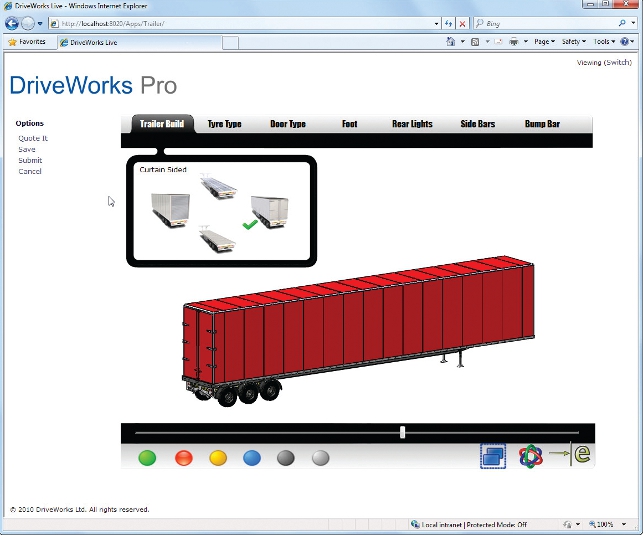

Trailer configuration including tyres, doors, lights and side bars

In a highly competitive global market, engineering departments are harder pushed, asking for more variation of a product and companies can’t get away with saying ‘You can have any colour you want as long as it’s black’.

“People need the configurability. They have it in their daily, private lives. I can go online now and configure my own pizza for delivery in the next half hour. And if people have that type of thing at home, they expect that at work as well. And there’s no reason why they shouldn’t get it.

But the reality is that if companies have to design more, given the same time frame, they have two choices. Employ more people or design quicker. And a good way to design quicker is to automate.”

Amidst the tough market conditions, there has also been a trend for the average lifecycle of products to drop. There has never been a greater pressure on designers and engineers to turn around complete products in such a short space of time.

And usually on a much more regular and shorter interval than has historically been the case. I’ve long been convinced that design automation is a good thing, even if just used to take care of routine and perhaps mundane repetitive tasks that many engineers face on a weekly basis.

Smith agrees, “Because product lifecycles are shorter, even if you have a product that’s partially configurable, the chances are your competitors will come up with a better product. “You only need to go to an electrical store and look at the choice you have in televisions.

When I was young, there would be eight to choose from. Now there are 80. And then each of those eight might have been on the shelf for a couple of years. Now it’s a couple of months.

“Rates of new product introduction are going up, but the engineers are busy doing work for production. If you want more throughput, automation is a fantastic idea and you could go a long way to freeing up

those engineers to develop new products if you automate repetitive tasks.”

The cloud & the future

DriveWorks has been ahead of the game when it comes to offering web-based services. With our industry’s current fascination with ‘The cloud’, how does the DriveWorks team’s feel about this subject?

“I think to some extent we have always been ahead of the game with the technology we have developed,” says Smith. “There have been web-based sales configurators out there for a while, but going back to our philosophy of enabling people to do this for themselves, and having a sales configurator online that you install, put your own data in, manage yourself and get up on the web, really quickly – we are ahead of the times with that.

“There’s been a definite shift in our sales, to more web-based licenses for exactly that. A quite definite shift. It’s partly driven by globalisation, with more companies being part of multi-national groups and selling products all over the world.

Web-based services or products like this are much more accepted now. Also, if companies are already engaged with rules-based automation, allowing their engineers to define and use the system, it’s a natural step for sales staff to use the same system, especially if it ‘looks good’ too.”

While it’s clear that the DriveWorks team has a good solid plan in place for its existing product offering, there has been much speculation and discussion of SolidWorks’ own future strategy, particularly when it comes to the move to the V6 platform and perhaps a cloud-based product offering.

It’s clear that anyone who’s embedded in the SolidWorks partner community is going to be affected and should at least be making plans for the future and trying to gauge how these changes will affect their businesses.

DriveWorks is a perfect example. It is sold through the VAR channel exclusively and its entry-level product is delivered in the install with every copy of SolidWorks. When talking about the state of flux Smith is more than upbeat and in relation to the VAR channel, he foresees a mix of both mergers and splits in different territories but maintains his commitment to the channel and existing distribution method.

“We’re committed to the SolidWorks reseller channel – partly because our product is a mass market one, partly because we want to carry on being a product development company that develops software, not a consulting company,” he explains.

When drawn on the subject of a new platform emerging from SolidWorks, Smith is similarly upbeat. “SolidWorks, as it is today, will be around for a good few years and we’ll continue to develop our product to automate it for years to come. From that point of view, it’s business as usual.

In terms of movement to the cloud, to a certain extent we have everything we need to support that and we’re already doing it with modules within DriveWorks Pro and some of the things we’re introducing with DriveWorks 8.0 even more so.

“In terms of us integrating with a cloudbased CAD system, we’re ready to roll and just need the CAD vendors to make that happen.”

www.driveworks.co.uk

Al Dean in discussion with Glen Smith and Maria Sarkar of DriveWorks