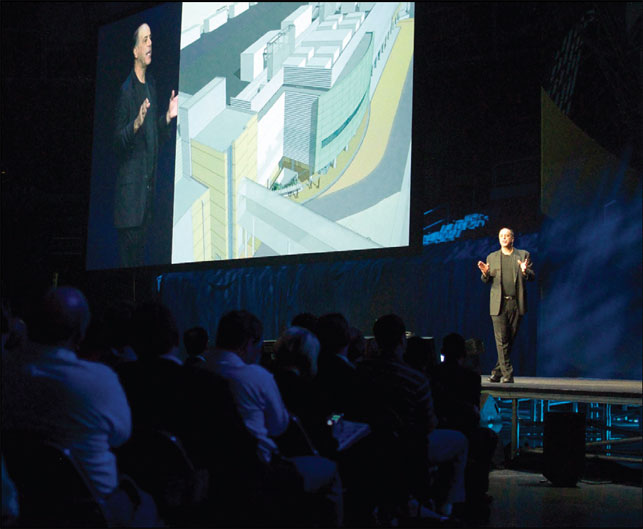

This is a big event. With a capital B. Having moved from the rather alarming Venetian to the Mandalay Bay, this year’s Autodesk University saw just under 6,000 attendees assembly from across the globe to learn about all things Autodesk. This year also saw the launch of AU Virtual, which allowed those not able to attend in person to view the sessions, keynotes and other activities on the web. So all told, this brought attendence to over 20,000.

The one session that’s worth the trip to Autodesk University is the Manufacturing Solutions keynote. This is where we get to see what Autodesk is working on, some of which, as history has proven, is due for the next release, some isn’t and is just at the concept stage. But the chances are that what you see here will make it into a product some point in the next two years (the next major release cycle is due around March next year).

Autodesk’s CEO Carl Bass takes the stage during the General Session

Here are the highlights:

Alias Sketch for AutoCAD was announced a few days prior to the event and it sees the integration of SketchBook like tools wasn’t too into AutoCAD. While the UI is adapted to its new home, the tools seemseem – per to remain emminently usable. One of the key points about SketchBook and why it’s seen such success is that it has a very stripped back set of tools, unlike Photoshop, and some specialised tools for design-led users.

Alias Freeform within Inventor brings a set of surface manipulation and concept modelling tools to Inventor. The concept is a single feature which gives you all of the dynamic modelling operations you need to quickly create complex forms, then use the more standard existing tools to add engineering detail. The toolset demonstrated looks extensive and powerful for manipulating geometry, using direct manipulation of curves, points and surfaces. The tools shown were reminiscent of the ISDX-based Style feature within Pro/Engineer and any advanced Pro/E user will tell you that its worth its weight in gold – and remains one of the best selling Pro/E modules.

Stratsys built the world’s largest 3D print of a turbo prop engine. All 188 components were produced in 4 weeks and assembled in 2.5 weeks. Cost of this monster was $25,000 compared to four times that for a conventional prototype.

With the Fusion Tech Preview still going strong, this came a not too much of a surprise, but this was the first time Autodesk has shown any of its direct editing tools fully integrated into Inventor. While things are shaking out with regards Fusion and Change management, if this is what the future of Inventor’s direct editing tools looks like, then there’s interesting updates around the corner.

Elsewhere, Autodesk is looking at making data management more user friendly, using graphical output, colour coding and data filtering, it allows you to grab the information needed quickly.

Also announced at the event and now available, Inventor Publisher Technology Preview is a3D product documentation application for creating assembly/disassembly instructions, manufacturing process instructions and all other manner of 3D documentation. It allows the creation of keyframe style animations with automatic and manual explosion tools as well as tools around the process, such as reversing workflows, managing views and step times as well as a range of output options, from DWF, through movies, PowerPoint and Word docs. There’s also an iPhone publishing platform which provides3D model animation, manipulation. It’s not clear whether data will be local or ‘in the cloud’, but it’s an interesting trend and one that makes huge sense for making documentation and instructions portable.

Part of the Design Matters showcase, the electric powered Misson Motor motorcycle can achieve 150 miles per hour for 150 miles with zero emmissions

The final demo showed how Autodesk are combining knowledge and expertise. Moldflow simulates how plastic is injected into a mould tool, but the results it gives are complex. The company’s knowledge of visualisation was used to provide an environment that shows users exactly how a part will look should manufacturing defects (such as sink marks) are left to enter into the manufacturing chain.

Conclusion We’ve barely done justice to the event with a single page, but what’s clear is that live events are still hugely popular and by supporting these with digital or virtual events, their reach can be truly global and all encompassing. In terms of what Autodesk is working on, the 2011 Manufacturing products (due in March/April 2010) look to be exciting for anyone within the Autodesk Manufacturing and Design community. We can barely contain our excitement.

au.autodesk.com

Al Dean reports from AU 2009 in Nevada