The Addaero Manufacturing team, from left to right: Dr Cesar Terrazas, Rich Merlino and David Hill

Only the bravest of entrepreneurs would consider launching a start-up based on 3D printing of metals, a process so new that it has so far barely made a dent in the world of manufacturing. To most, the barriers to entry would seem insurmountable.

Entry-level machines cost six figures and more. Materials and peripheral machinery just add to the costs of getting started. Potential customers, meanwhile, remain wary of the output and reluctant to take a gamble on parts created in this way.

Regardless of the obstacles in its path, Addaero Manufacturing has forged ahead, hoping to create an early-mover advantage – and a name for itself – as a 3D printing in metals specialist among the aerospace companies it targets.

The founding team at Addaero certainly have some impressive experience to back up their vision. Rich Merlino and David Hill have, between them, some 30 years in engineering and supply-side roles at aerospace engine manufacturer Pratt & Whitney.

Back in 2013, they decided the time was right to launch their own metals 3D printing bureau and they cannily selected as its location the city of New Britain, Connecticut, in the heart of the state’s ‘Aerospace Corridor’.

With Merlino appointed as president and Hill as vice president of operations, Addaero invested in its first metals 3D printer in mid-2014, choosing the Arcam A2X EBM 3D printer. This was one of only 35 in the US at that time, making it a bold choice in a market more focused on laserbased machines.

In order make their selection, Addaero’s founders relied heavily on the opinion of a third team member, Cesar Terrazas, a Ph.D-level materials scientist with a six-year track record of working with Electron Beam Melting (EBM) technology at the University of Texas El Paso (UTEP).

“EBM gave us the ability to get into a market that was at an even earlier stage,” says Hill. Terrazas’ rare experience, he adds, made the opportunity too good to miss.

The choice of New Britain, meanwhile, meant that the machine would be close to two of Arcam’s largest existing customers. With Arcam service teams close at hand, and potential aerospace clients on its doorstep, the bureau had a great launchpad for its ambitions from day one.

A prototype rocket nozzle part for NASA’s future Space Launch Systems, 3D printed in Inconel by Addaero

Plan of attack

Addaero’s plan was always to be more than simply a parts provider. In an industry lacking a full industrialisation process for 3D printing in metals, the company’s founders saw an opportunity to establish their own process, in the hope that would-be clients would see the value there and adopt that process themselves.

High on its list of R&D priorities is materials expansion, driven largely by Terrazas’ background working with almost a dozen different materials in his work at UTEP.

New materials and workflows are an important point of differentiation, since there are far fewer materials available for EBM than for laser sintering.

At present, the team works almost exclusively with Titanium 6AI-4V, but can also work with Iconel 718, which is suitable for use in extreme environments of pressure and heat. New applications for stainless steel are being explored, and Terrazas’ research extends to copper, iron and cobalt chrome.

Says Hill: “We don’t have to worry as much about residual stress, because with EBM, you build the part at high temperatures, as opposed to [with] laser which, because it builds at more or less room temperature, can create a bunch of residual stresses in the part.”

EBM can also provide a faster build, especially with titanium, adds Hill, allowing for the stacking of parts in the build area – a huge benefit from a production standpoint, he says. That said, the surface finish tends to be rougher with an electron beam than a laser, he adds, “so there’s pros and cons all the way.”

The post-processing of parts is another key R&D area for Addaero as it looks to make economies in the process that will position 3D printing in metals as a viable competitor to traditional part manufacturing.

An EBM surface finish is roughly equivalent to that achieved with sand casting – but Addaero focuses on machining the final part as it would with any other titanium or Inconel casting.

With chemical milling and tumbling also options, the effects of finishing on part geometry and tolerances need to be factored into the design from the start. In other words, Addaero is building parts knowing that these will lose a certain amount of mass by the time they’re finished.

If the part needs to be machined, the designer can build the holding fixture into the part to position it correctly for the CNC machine.

“Maybe if you had the forethought, you could do that with casting, but with additive, you can do it on a much more iterative basis, and that can really speed things up,” says Hill, adding that this is all part of the service offered to clients. In this respect, many of them require a certain degree of education, he says.

Addaero’s now-modified Arcam A2X electron beam melting machine

Adventurers in rocket science

A clear exception to this rule, space agency NASA needed little introduction to 3D printing in metals when it approached Addaero to build components for its prototype RS-25 engines.

Since these are intended to power future Space Launch Systems (SLSs) on deep-space exploration missions beyond Earth’s orbit, part failure is not an option.

The rocket nozzle part that NASA needed had to include curved channels running through it, in order to convey a coolant that would keep the walls of the nozzle cool.

These curves would be impossible to produce using traditional means, but for Addaero, this was a challenge perfect for testing the A2X’s ability to print in Inconel.

Having added extra material to the initial design that would later be removed in the machining process, the 2-inch high and 5-inch diameter prints would be some of the largest ever produced in the material.

The factory-issue 200mm x 200mm x 380mm build plate of the A2X was easily replaced, but the part size brought the new challenge of maintaining a constant build area temperature for the duration of the build.

Despite the media attention that NASA attracted with the news that it was 3D printing components for its rockets, for Addaero, the 3D printing process was only the first stage in building the rocket nozzle.

The 3D printed Inconel parts were machined and welded to larger flanges, before being finished

As Hill puts it: “The parts aren’t done when you get them out.” Once out of the printer, he continues, these parts needed to be rough-machined first and then welded to larger flanges, before they were machined to the dimensions detailed in NASA’s brief.

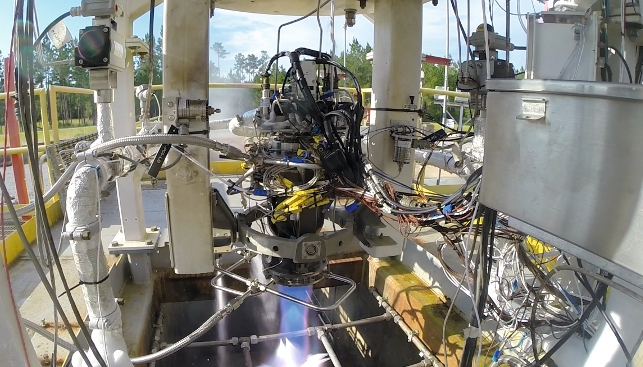

A test fire of an RS-25, featuring the parts, took place in June 2015. “For the parts that we gave them, it was a successful test,” Hill reports. NASA, he continues “got the reading they were looking for and the temperatures they wanted on the nozzle.”

For Addaero, the likes of NASA embracing metals 3D printing for niche jobs is just the start of a much bigger adventure. The company’s hoping to capitalise on its early-mover advantage while there’s still plenty of scope for developing intellectual property and establishing industrial processes.

When original equipment manufacturers approach Addaero, says Hill, they’ll find it more than ready to respond to new requirements and answer new questions – questions such as “How often did you test the powder for quality?” and “How many times can you reuse the powder?”

From an aerospace perspective, Hill sees a lot of certification and quality requirements becoming industry standards – just as they are in forging or casting.

He’s also adamant that improvements to printers over the next five to 10 years will open up new markets. “I think faster, better, stronger – that’d all be nice. That’ll help the growth of the industry. In our experience, the larger companies look at [the technology] and ask ‘How is this going to save me money?’ Initially, that’s how a lot of people are going to look at it.”

Despite Addaero’s pioneering spirit, Hill doesn’t overplay his view of the future. “I don’t think that in my lifetime, additive manufacturing will replace any of the other processes,” he concludes. “It’ll just be another arrow in the quiver for manufacturers.”

NASA successfully tested Addaero’s rocket nozzle parts in a live-fire test

Inside Addaero’s workflow

Before an electron beam is even fired, the part (in this case, a turbine blade) is prepared for post-processing by attaching a fixture to the customer’s 3D CAD.

Machining the part allows Addaero to prepare surfaces for welding, and to meet high accuracy dimensions while applying the correct surface finish.

Printed from Titanium on its Arcam A2X 3D printer, the surface texture straight off the print bed is similar to that of a sand-casted part. The addition of a fixture allows it to be secured easily at the correct angle on a 5-axis CNC mill for finishing.

A look at Addaero’s metals mission for NASA, using cutting-edge 3D printing technology

Default