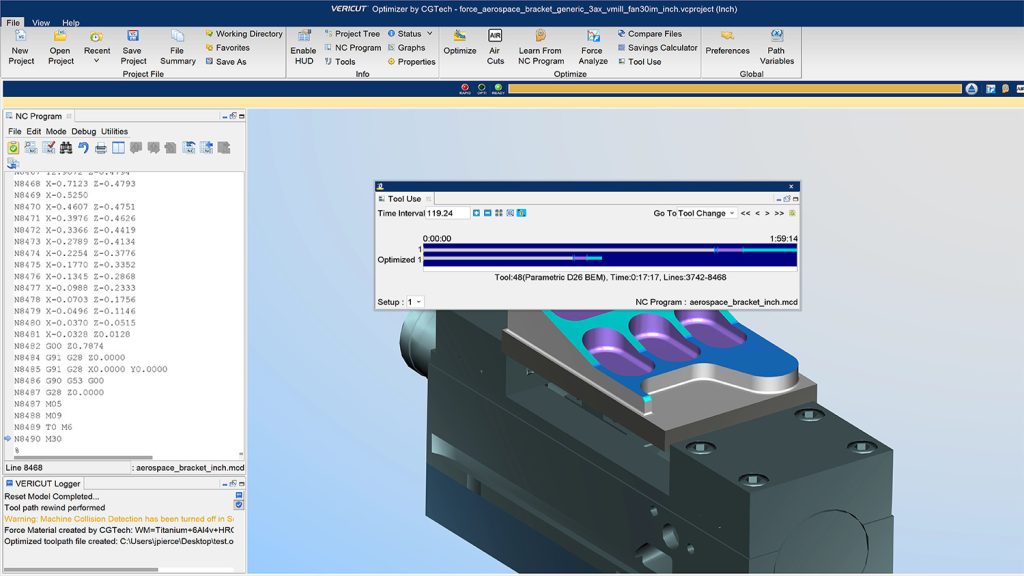

Vericut has announced the release of Vericut Optimizer, a stand-alone solution which uses data-driven optimisation strategies and tool paths to improve CNC machining programs.

While Optimizer is similar to Vericut’s existing Force software, which can only be used once Vericut has been purchased, machine shops will be able to use the software without buying Vericut first.

It is intended to be used by companies of all sizes in all industries.

Vericut Optimizer integrates with APT/CL files and G-code NC program outputs of most CAM systems.

It reduces machining cycle times and captures performance data, providing ‘the most accurate cut-by-cut analysis on the CNC market’.

Tool life is extended with Vericut’s tool performance data, including industry-recommended feeds and speeds for common cutter types and materials.

A stock material catalogue is included and contains over 150 dyno-tested stock material-cutter combinations.

Other features include a preconfigured head-up display, an NC program display with review capability, an optimisation savings calculator and the ability to compare original files with optimised NC programs.

Optimizer can also import and create cutters through assigning stock and NC programs to the project.

“In just a few clicks, Vericut Optimizer empowers manufacturers to optimise their NC programs effortlessly, regardless of their existing software set-up,” said sales manager Scott Ravenscroft. “Suitable for use on three, four or five-axis CNC machines, Vericut Optimizer concentrates solely on optimising your programs to deliver unmatched improvements in cycle times, tool life and part quality.”

Vericut Optimizer will be launched on 3 October 2024 at the Grob Machine Tools UK headquarters in Stratford-upon-Avon.