Hexagon and Authentise have partnered in a move to connect the entire additive manufacturing process – from design through to manufacturing operations and quality assurance.

Engineering data from the design phase, manufacturing operations, materials properties and quality data from validation and inspection processes are listed as a whole by Hexagon as the key to automating serial production. However, the technical challenge of connecting these have hindered the ability to consistently apply AM to new designs.

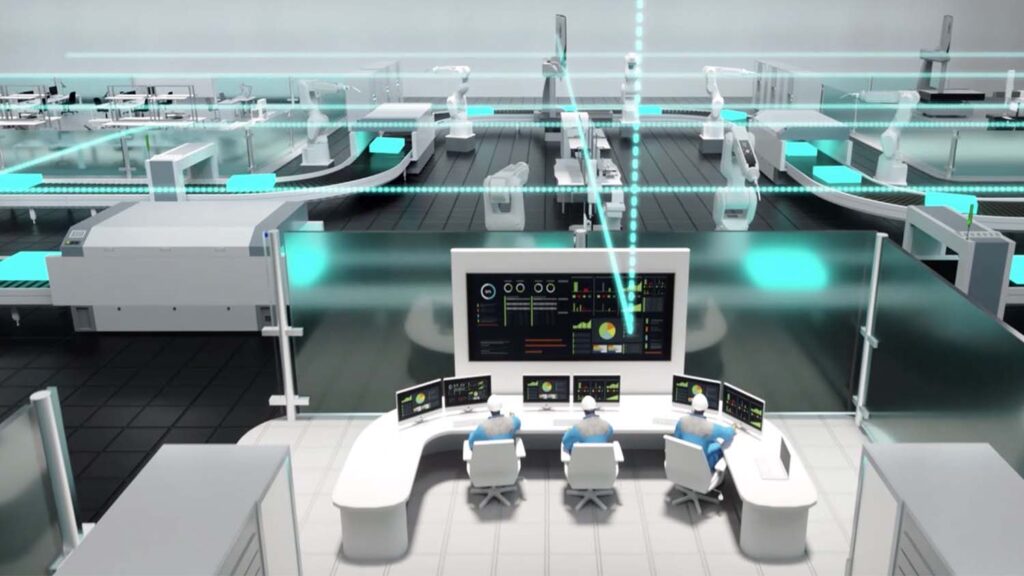

Hexagon’s Manufacturing Intelligence (MI) division and Authentise are developing new solutions delivered to apply Statistical Process Control (SPC) with Machine Learning (ML) and Artificial Intelligence (AI) methods to mitigate waste and quality issues during the design phase and improve the repeatability of additive manufacturing processes within a site or between global locations.

A goal of the partnership is clearly to connect more of Hexagon’s swathes of acquisitions from recent times, and put them into a framework that can be controlled and monitored, with a certain level of the legwork being automated.

A shared commitment to open architectures that integrate data and automate workflows between Hexagon’s kit and third-party equipment and software manufacturers is maintained, dismissing any fears about it becoming an immediate closed network.

“Together with Authentise, we are building a next-generation framework for our customers to manage flexible, fully digitised production workflows in private cloud environments,” said Mathieu Pérennou, global business development director AM, Hexagon MI.

“For manufacturers, AM is a complex and changing market with many excellent tools, printers and materials to apply. We believe our open and flexible systems will enable us to respond quickly to customer’s needs and integrate with their unique environments.

“This will connect the data flow and help streamline their workflows in all stages of the AM process – before, during and after production and support their specific standards or compliance needs.”

Authentise CEO Andre Wegner, added, “We are excited to combine Hexagon’s solutions with our open workflow management engine to offer a unique end-to-end solution platform.

“Integrating data from Hexagon’s best-of-breed software and sensors helps deliver a seamless experience for users, automation across their process, and unlocks the ability to learn from data. This partnership represents a step change for the industry – together we’re delivering the integrated digital thread for additive manufacturing that customers have sought for so long.”