Ford Mexico is using insights gleaned from its implementation of Altair’s Knowledge Studio machine learning and predictive analytics software to enhance its stamping process selection and boost its first time through (FTT) rates

Sheet metal stamping is fundamental to the automotive manufacturing industry. A vast array of different tool, die and process combinations are employed to create an equally diverse array of components. Traditionally, identifying the optimum stamping process for a given part design has been a labour-intensive and time-consuming task, one that relies heavily on the stamping engineer’s knowledge and skill level.

To address this issue, Ford Mexico began documenting successful metal stamping production runs over a five-year period.

Management’s goal was to capture in-house domain knowledge and best practices in order to explore ways to speed the selection of the best stamping process for future production runs.

The aim was to deliver business benefits including increased plant efficiency and part quality, reduction of scrap material and more rapid training of new personnel.

Ford Mexico – tackling the challenge

In many production facilities, multiple sheet metal stamping processes are deployed to form nested and individual parts. These include progressive, transfer and tandem press lines. For any given part design, many factors are involved to determine the best or most efficient stamping process, such as the material type, thickness, part width and desired surface finish.

Success or failure in selecting the right process relies heavily on the experience and expertise of the individual manufacturing process engineer involved in making it.

However, growing design complexity, non-conventional material types and numerous process combinations can challenge even the most senior process engineer. That often results in a labour- and material-intensive, trial-anderror prove-out process.

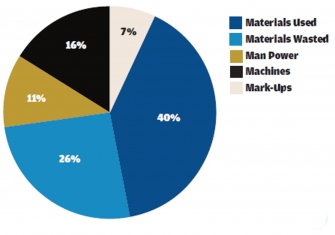

Material utilisation is a particularly critical benchmark. Most automotive plants expect around 60% material utilisation in their stamping mills. The remaining 40% goes to waste.

Ford’s objective was to improve on these numbers, while simultaneously improving the initial selection of the right stamping process and increasing first time through (FTT) rates.

To move towards achieving these goals, Ford Mexico began documenting processes and quickly amassed a valuable asset: vast quantities of clean data associated with successful production runs.

Spanning a five-year period, process engineers recorded successful stamping processes for thousands of parts. Captured in this historical data were valuable insights, but the question now was how could they use this information to help automate and guide the selection of the best stamping process for a given part design.

Ford Mexico – approaching Altair

Ford Mexico has had a relationship with Altair for the last 50 years, but the team there first learned of Knowledge Studio, Altair’s machine learning and predictive analytics solution, via a technology briefing. That led them to approach Altair with a view to implementing the solution.

Leveraging the data Ford Mexico had collected for over 3,000 stamping processes already identified as being representative of future requirements, Ford’s stamping domain experts and Altair’s solution architects collaborated to develop an accurate, reliable machine learning model with Knowledge Studio.

The software offers 15 different machine learning models, enabling users to explore, select and train the model that best fits their data. Using subsets of its data, the team at Ford Mexico ran a series of tests to determine which was most effective. With an accuracy rate of over 90%, the decision tree model produced the most consistent results.

In the process, a surprising – and valuable – discovery was made. In terms of selecting the optimal stamping process, the most important factors are the overall dimensions and thickness of the finished part. Alone, these factors are not enough to make a final decision; however, when combined with all the other data points, Knowledge Studio’s machine learning algorithm provided Ford Mexico with results close to 100% accurate.

Predictive powers

The machine learning-enabled predictive power of Knowledge Studio proved to be highly accurate and successful in largely automating stamping process selection at Ford Mexico.

By minimising manual trial-and-error process validations and rework, more time was freed up for stamping process engineers to address the most difficult and complex part designs, further enhancing production efficiency and business value.

Overall, projected throughput increased by a factor of three and increased FTT rates resulted in reduced rework time – all without increasing resources. In addition, the Knowledge Studio machine learning model was effective in capturing Ford’s in-house domain knowledge to support a faster learning-curve for training of new personnel.