The launch of CAM Assist 2.0 by CloudNC promises to combine the speed of AI-powered toolpath generation with new step‑by‑step oversight, giving programmers even greater control.

Improved workflows within CAM Assist 2.0 let users configure machines, materials and tool assemblies in minutes, review AI suggestions as they are made, and export approved machining strategies directly into their CAM platform.

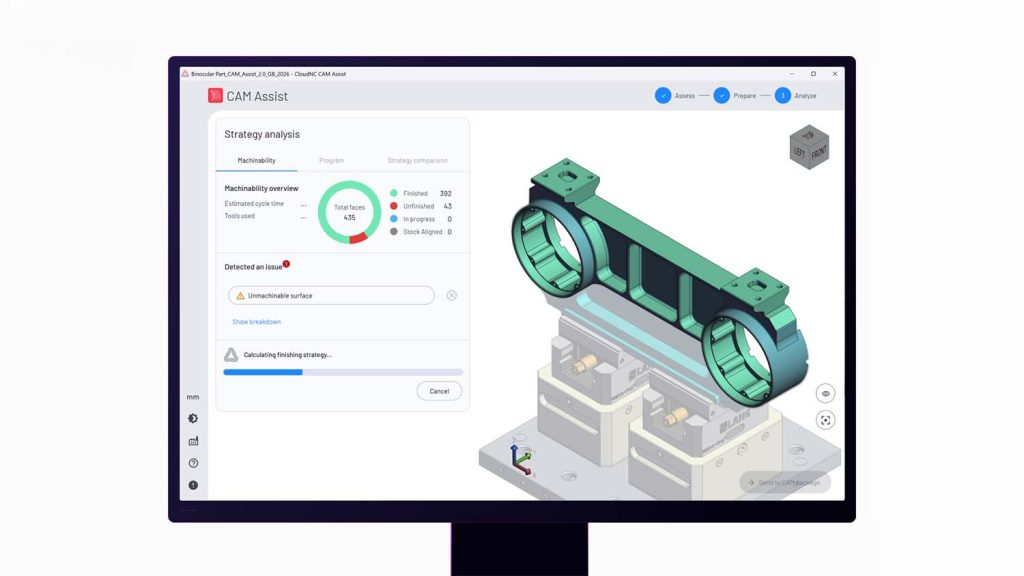

The web-based CAM automation application that initiates from the user’s CAM package, supporting 3-axis and 3+2 operations, featured a new web UI, from which the user still generates a working toolpath by pressing the CAM Assist button.

Now, CAM Assist 2.0 breaks out the AI stages so that parts can be assessed prior to running. Moreover, as files are being computed, control over strategy editing is passed to the user.

CloudNC CTO Dr Andy Cheadle, said: “CAM Assist is being adopted globally by tech-enabled machine shops who believe in the power of AI to transform their operations. The new 2.0 upgrade shows that AI and human expertise can work side by side, improving a machinist’s productivity even further.

“By letting users see and ultimately influence the AI’s decisions as they happen, we’re helping shops program faster and with higher confidence, resulting in an even more useful solution that machinists and programmers can trust implicitly.”

Other upgrades include ‘one-click’ configuration to let machinists start programming in minutes; Context-aware recommendations – shaped by part geometry, machine constraints and tools and fixtures – appearing precisely when choosing strategies, tool assemblies or feeds and speeds, increasing feedback; and the ability for a human to inspect, review and alter any toolpath before it’s handed back into the user’s preferred CAM package for code generation.

With cloud-storage of these elements, CloudNC says that CAM Assist can run faster, utilise more extensive tool libraries and parameters and serve as a common source between CAM programmers, helping standardise output and achieve consistent results across a machine shop’s output.

The launch of CAM Assist 2.0 comes as CloudNC celebrates CAM Assist being used by over 1,000 machine shops globally to accelerate CNC programming with AI.