An array of new and enhanced functionality, and integration with Workplan, has been announced for the latest release of Hexagon’s Alphacam 2021.

A CAD-CAM software for woodworking, metal and stone cutting, the emphasis behind AlphaCAM is found across its wide array of modules, include Routing, Milling, Turning with 2-Axis to 5-Axis Machining.

The latest offering looks to put the software at the forefront of helping manufacturers create Smart Factories, in line with Industry 4.0, and adding new automation functions to assist users to prepare jobs for processing as well as managing them.

AlphaCAM product manager Chip Martin says the order of layers and machining styles can now be modified.

“The order defined in the layer mapping setup will be used for applying the toolpaths, and users can now control the order of the toolpaths while defining how the part will be machined. However, the Machining Order option can still be used for ordering operations by tool.”

Automation Manager now shows the list of parts that could not be nested, so the operator can either cancel them or process them in a future job.

An option to create a new job containing only the parts that could be nested is also available for further automation.

Enhancement to the user interface helps provide further control on which part properties the operator wants to see.

“In previous versions, users could only see the part names, and needed to click each part individually for more information,” says Martin. “Now they can see key details such as height, quantity, if the part is nested, and any of the part’s properties.”

The new Folder Watcher allows jobs to be processed autonomously via Automation Manager.

This tool should be ideal to use in both a well-established manufacturing process, as well as where orders are created through ERP software or any other system outside AlphaCAM.

“It watches a folder, and as soon as an order is created, it automatically processes it using Automation Manager without the user having to do anything,” explains Martin.

Geometry Node editing in the CAD element of AlphaCAM has seen improvements added, with Hexagon saying it now allows multiple elements to be converted to a single line or arc.

Prompts will also appear about node selection when two or more nodes overlap.

Hexagon says that AlphaCAM’s ability to machine solids directly, without the need to create geometries, has led to a major improvement in this version regarding automation.

“Previously, it’s not been possible to automate this, as the solid faces to be machined always had to be picked manually,” says Martin.

“But in the same way that geometries in layers can be machined using Machining Styles, solid model faces can now be added to layers.

“Machining styles are created from a variety of operations, and users can easily machine solid faces in that layer without having to manually select the faces.”

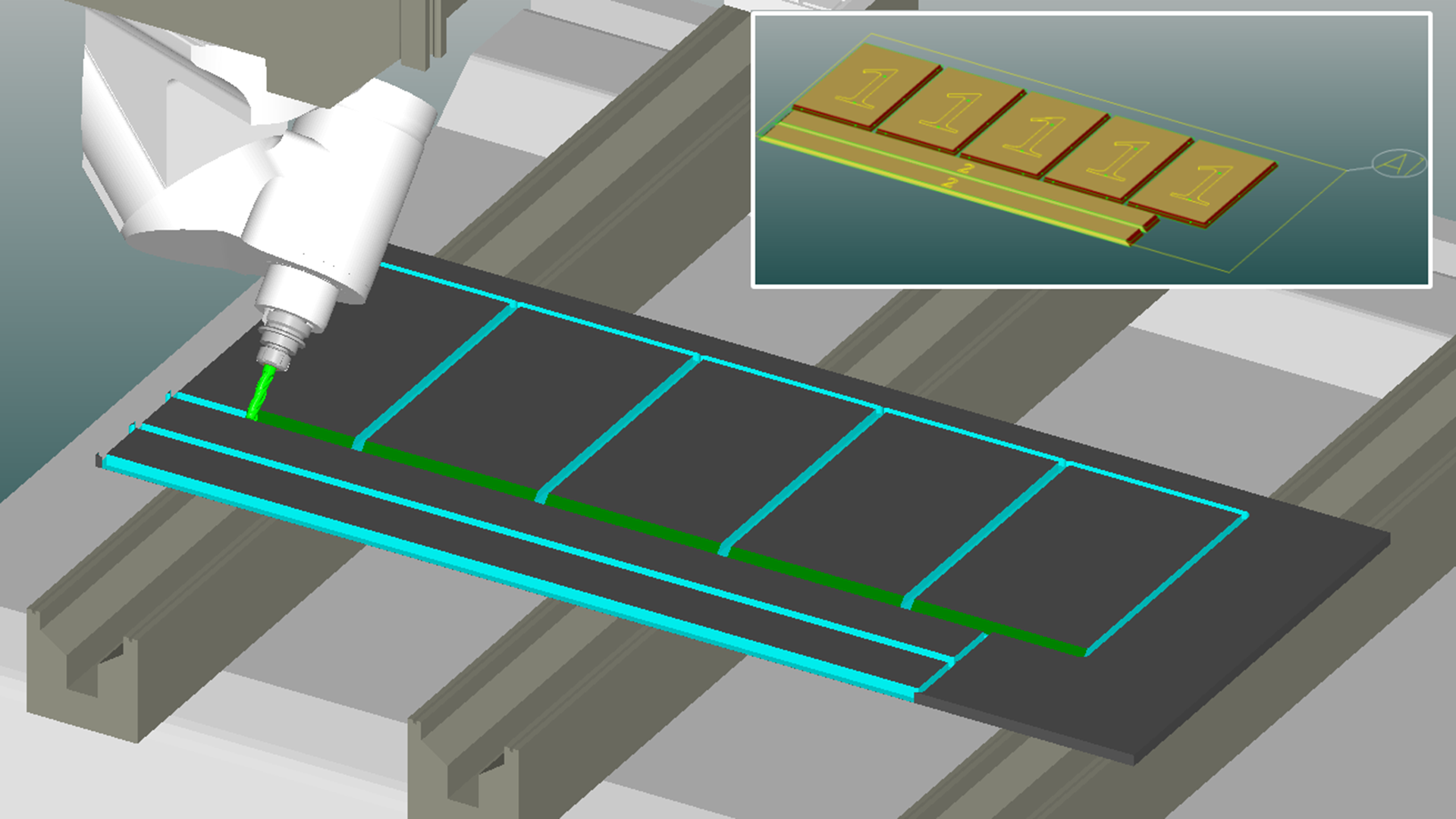

A new option to Optimise Toolpath Overlapping looks to improve material usage in nesting. It allows toolpaths around different parts to overlap, provided the tool doesn’t cause any damage.

Additional distances are applied where required to protect the parts, while still allowing the toolpaths to overlap.

The new option should also add notable nesting improvements when tools with a larger diameter are used inside the part, but a smaller tool is needed to cut the outer shape, with the nesting engine using the outer tool diameter to define the overlap.

Another enhancement enables solids to be nested with their geometries. “As nesting is a 2D solution, it’s not yet possible to nest parts containing workplanes, but as solids can now be placed in the nested sheet it’s possible to machine the solid after it’s been positioned there,” says Martin.

Toolpaths can now be applied directly to the solid and solid faces and the user can even carry out another operation to extract geometries from the solids, and then machine those geometries.

“It means that after nesting, it’s possible to machine geometries and solid features using more than 3-axis.”

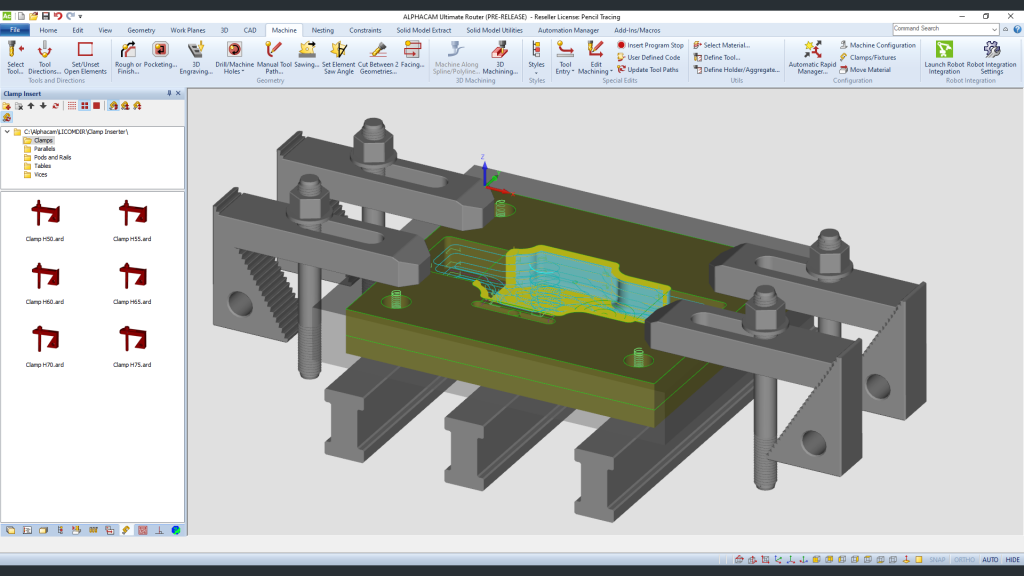

A new project manager page called Clamp Insert, offers the ability for clamps and fixtures can be dragged and dropped into drawings, and then an XY location chosen to insert them. Once in place, AlphaCAM is able to automatically read the material thickness and places the clamp at the correct Z level.

Martin adds that future releases will extend it to more complex clamps with several movable components, such as rails and pods.

NCSIMUL Essential has been integrated into AlphaCAM, replacing the external simulator in the router and mill modules, giving the ability to simulate 3- to 5-axis toolpaths and machines with movable clamps.

Finally, AlphaCAM 2021 integrates with Workplan and nesting offcuts, connecting directly to a Workplan server and using the materials in its database, meaning the operator knows the exact amount of material in stock to run a job, as well as making it easier to manage offcuts.

“Users reserve sheets and define which offcuts will be generated by the job. Confirmation that the job has been processed, is done using Workplan windows tablet application. The main material will be deducted from stock, and the offcuts added to the database, where they’ll be available for future jobs,” concludes Martin.