The iconic rimless,hingeless and screwless Titan Minimal Art glasses

The design philosophy behind eyewear company Silhouette’s iconic Titan Minimal Art (TMA) series is quite simple, according to its head of design Roland Keplinger. The goal is to deploy precisely as much design and material as is needed – no more, no less.

The TMA series dates back to 1999, when the company first succeeded in producing eyewear completely free of frames, hinges and screws. These glasses are as light as a feather – just 1.8 grams – and aim to deliver the ultimate in comfort.

Few eyewear designs can boast as prestigious a history as Titan Minimal Art. In 2000, it even journeyed into space with NASA astronauts and was designated ‘Certified Space Technology’ by the Space Foundation, thanks to a design pared down to just the absolutely essential elements.

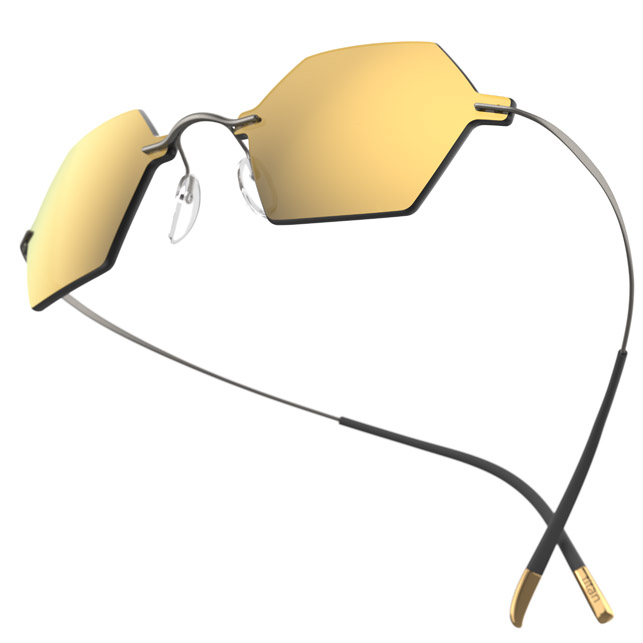

To celebrate the TMA series’ twentieth birthday, Silhouette Eyewear has released a new range of sunglasses, the Special SUN Edition, featuring four new models with geometric, architectural shapes and minimalistic lines.

As Keplinger explains, “Material is key, because we are working on the limits when it comes to wall thickness. We decide on the material at a very early stage.

In our case, it’s either titanium or SPX, a special polymer developed by Silhouette Eyewear.” This material can be adapted according to how it’s being used, he explains, “for example, flexibility versus stiffness, or whether it’s a frame or a hinge part.” The titanium used is a special beta titanium alloy, adjusted to Silhouette’s specific need to produce sophisticated rimless and hingeless frames. As Keplinger points out, “We are talking about tolerances of 0.02 millimetres.”

A pair of Silhouette’s original rimless spectacles from the 1970s, which paved the way for the Titan Minimal Art models of the 1990s

Silhouette Eyewear – from sketch to prototype

Designs begin with a briefing and then some sketching, but progress quickly into 2D and 3D, he says. The first 2D concepts are digitalised in Adobe Illustrator and Photoshop, to create initial visualisations.

In the design department, Solidworks is used for design data, allowing the team there to produce 3D renderings in Keyshot to better highlight colours and trims.

“In the first round, we choose three to four concepts that go into prototypes,” says Keplinger. “With those first models, we test the functionality, the size and wearing comfort and we also try to use the exact material, which sometimes is not so easy.”

The trickiest thing to achieve is the perfect curvature and shape of the TMA models. The perfect line has to be achieved not only in the closed, but also in the ‘worn open’ situation.

“When you have polished surfaces, you see every mistake or dent. So, every day we work towards reaching perfection!” says Keplinger.

The next step involves transferring design data into manufacturing data with all the tooling requirements. Here, Silhouette uses Siemens NX.

To celebrate the iconic model’s twentieth birthday, a Special SUN Edition of the unmistakable Titan Minimal Art has been released

A further round of prototypes provides additional checks, to see if everything looks and feels right.

“If it’s a complex model, we need to do a few more rounds, also producing test moulds,” Keplinger explains. Prototypes are essential when it comes to frames, he adds – especially for a firm that boasts that ‘Nothing feels like a Silhouette Eyewear.’

“You can’t simulate that,” he says. “You have to try and wear.” Some prototypes are still made by hand, especially for metal frames where 3D printing is not yet at the maturity level needed.

For the SPX range of lightweight, full-rim eyewear made from resilient polyamide, by contrast, more and more 3D printing is used, “but sometimes we have such tiny and thin elements that we have to use different production methods” says Keplinger.

“My aim for the future,” he continues, “is to use more virtual simulation when it comes to properties like flexibility and distortion. We already simulate the die-casting process to know how the moulds are filled.”

With that in mind, it seems that Silhouette Eyewear has the vision it needs to deliver several more decades of minimalist fine-tuning for its TMA series.

Silhouette Eyewear dons shades for bright future

Default