As governments around the world plan to bring in tougher laws on engine emissions in order to meet air-pollution and fuel consumption targets, this poses a huge challenge for the makers of small (less than 250cc) low-cost engines.

The machined parts were delivered to Scion-Sprays within three days of the company having accepted the quote using Proto Labs online quotation systems

They find themselves faced with a decision to either invest in the development of more efficient engines or see markets close to them.

Thankfully, a company based at the Hethel Engineering Centre near Norwich has developed another solution – and after years in its development has recently secured its first commercial order. Scion-Sprays is made up of a group of engineers specialising in the development and manufacture of affordable engine management systems that it’s hoping will give OEM customers a real competitive advantage.

Our first commercial product is a fuel injection system specifically designed for a European manufacturer of light motorcycles and scooters,” explains Richard Hoolahan, manufacturing manager. “This new system will cut emissions of HC+NOx (the cause of photochemical air pollution) by around 35 per cent, and CO emissions by over 80% compared with a standard engine. It will also save 30 per cent on fuel.”

Founded in 2002 by Jeff Allen (a former chief engineer at Lotus Engineering) the firm grew out of research into the electrostatic atomisation of fuel. In the process, Allen (now the firm’s technical director), came up with the idea of a small, low-cost ‘constant volume displacement pump’ to control fuel flow rates.

“That pump proved to have greater market potential than the original research suggested because of its efficient, clean-burn credentials and its simplicity,” says Hoolahan. So with backing from an ‘angel’ investor, who saw both the business and the environmental benefits of the technology, Allen and a small team set about developing Scion-Sprays’ engine management system called Pulse Count Injection (PCI). Now, with the help of rapid prototyping services Firstcut and Protomold from Proto Labs, the company is planning to move from the development phase and into production.

On the pulse

PCI works by calculating the amount of fuel needed in each engine cycle and then applying a precise number of pulses of a fixed volume of fuel across the cycle.

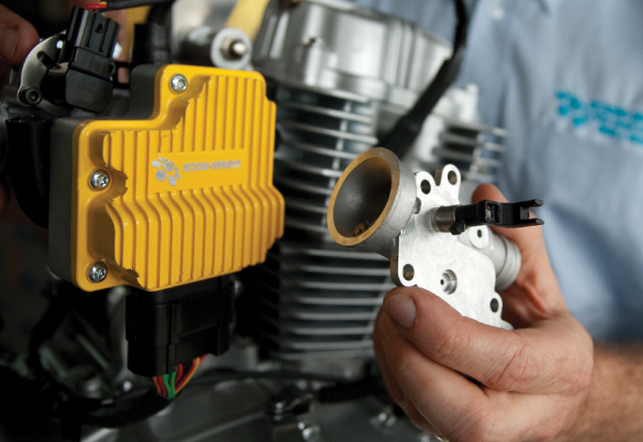

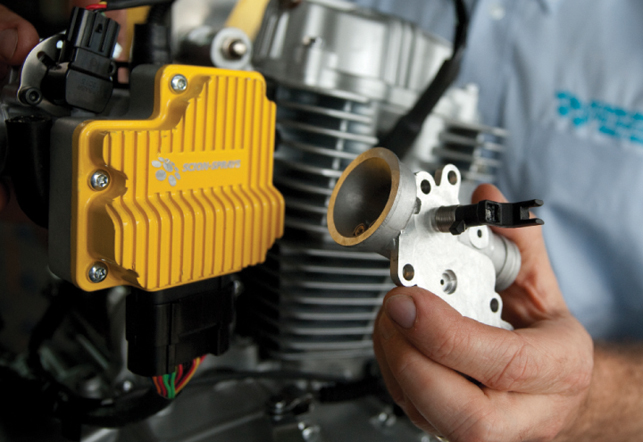

By 2006, Scion-Sprays had produced its first working PCI prototype, which in turn led to the development of a fully integrated Quantum Fuel Injection (QFI) system. The modular design of the QFI system includes a throttle body (designed by Hoolahan when he was the company’s design engineer), PCI technology, sensors, idle control and ignition.

Because it has no high pressure pump and significantly fewer moving parts, QFI is simpler to build and maintain than a standard fuel injection system based on Pulse Width Modulation (PWM). Nevertheless, PCI technology enables QFI to deliver metered fuel bursts at up to 1000Hz and fuel atomisation at 50-80 microns SMD (Sauter Mean Diameter).

This combination of accuracy, reliability and ‘smart controls’, along with its low unit cost, makes QFI ideal for motorcycles and mopeds up to 250cc, and small utility-engines (such as those found in lawnmowers, strimmers and leaf-blowers), which cannot justify the additional cost of a standard PWM system.

An added attraction for OEM’s is that the throttle body matches the carburettor footprint in existing engine designs with minimum additional wiring and sensors and QFI-enabled engines are also Euro 3 and China Stage 3 emissions compliant, and bio-fuel compatible.

It was while developing a prototype of its QFI for a prospective European customer in the early part of 2010 that Hoolahan turned to Proto Labs. “I needed about 15 to 20 pre-production QFI systems for customer-testing, which meant they had to be fully functional and made from similar, if not the same materials that would be used in actual production units.

I used different rapid prototyping services to produce less-critical components,” he says. “But chose Proto Labs for the throttle crank and the stepper motor arm because there could be no compromises in the mechanical qualities of those parts: and the production method and the materials would be very similar to what we would use in the final version.”

Taking it online

Hoolahan decided to use Proto Labs’ Protomold injection-moulding service to produce the stepper motor arm from glass-reinforced nylon. However, he says: “I chose Firstcut’s machining service to make the throttle crank from the same material, partly because I wanted to compare the processes and partly because creating a mould for the throttle crank would not have been cost-effective. At this stage in the product development, it is very important to minimise costs.”

Online quoting systems rarely work as advertised, but this time they did

Hoolahan contacted Proto Labs using the company’s two interactive, online quotation systems: Protoquote and Firstquote. Both systems let him upload his 3D CAD models and then within hours sent back an accurate quote – not an estimate. “I was very impressed with the process, it was so easy,” claims Hoolahan.

“Online quoting systems rarely work as advertised, but this time they did. The Proto Labs systems gave us a complete price based on our CAD models; a price that was updated instantly when we changed the quantity or material, so we knew what we would pay for what we wanted. I also liked the personal touch! For example, Protomold suggested a small, design refinement, in this case adding draft angles to help release the motor arm from the mould.”

The machined parts were delivered within three days of Hoolahan accepting the quote. “The moulded parts took slightly longer but that is because of the tooling required. Nevertheless, they were with me in a matter of days, not months, like other suppliers,” he says.

Overall, Hoolahan was very impressed with the service, including the quality of the finished components: “Proto Labs delivered exactly what they said they could which was exactly what I wanted. The QFI system performed as it was designed to and, as a result, we secured our first commercial order from that European motorcycle maker worth €4 million over the next 3 years.”

www.scion-sprays.com / www.protolabs.co.uk

Proto Labs drives up profitability for Norwich engineering firm