It sparks into action with a soft whirr that builds into a gritty chatter as it comes into contact with a surface – but what is most noticeable about seeing one of Mirka’s electric sanders in action is the conspicuous lack of dust.

Like all power tools, orbital sanders need to be tough to meet the demands placed on them in environments known for their dust, dirt and mess, from grimy auto body shops to sawdust-strewn furniture factories.

Since Mirka’s inception almost 75 years ago, however, a key challenge has been dust removal – for superior results, greater longevity of equipment and healthier workplaces for users.

The Finnish company’s background in industrial abrasives has led to several important innovations in its power tools. In particular, a gauze-like backing enables dust to be extracted straight from the contact service, thanks to a vacuum cleaner attachment. As power tools unit manager Veli-Pekka Vasti explains, “You have a lot of holes for the dust to be removed through, from the sander and into the vacuum cleaner.”

Meanwhile, non-stick coatings ensure that removed material doesn’t build up on the sander pad, where it could interfere with achieving a perfectly smooth finish.

Vasti explains that Mirka’s history and background in industrial abrasives has allowed it to make the most optimised connections between abrasives and tools, putting it ahead of its competition.

Mirk – change of direction

It was back in 2005 that the team at Mirka began to wonder whether the company could apply its knowledge and expertise in abrasives to design its own line of electrical power tools.

New lightweight, low-maintenance brushless motor technologies looked like the ideal choice to replace the pneumatic systems that were at that time prevalent in industrial settings.

Air-powered pneumatic units all need to be hooked up to a central compressor unit in a workshop, with each tool generating high levels of vibration caused by the physical mechanism inside.

That can be a big problem for health. ‘White finger’ is a recognised complaint, where vibrations from power tools used for long periods of time can cause tingling and numbness in the fingers, and in some cases, permanent loss of feeling.

Demands and expectations in industrial settings have changed, too: downtime of a central compressor could be catastrophic for a busy workshop facing deadlines, while many workers want the flexibility and freedom that electrical tools allow. If one motor breaks, then the rest of the tools aren’t affected, and individual tools can be taken off site or used in another part of the facility.

According to Vasti, the development team proposed the creation of an electrical Mirka sander as small and as light as a pneumatic sander. “At that time, it was typical that universal electrical motors were used. There were brushes and it was heavy, but we felt that it would be possible to try and use brushless motors with the sanders.”

Mirka’s first electrical product, CEROS (Compact Electric Random Orbital Sander), was launched in 2009 and, combined with Mirka’s specialist abrasives, it proved revolutionary. A year later, the company officially formed its power tools division, now a 40-person department dedicated to design and production, based just outside the rural village of Jeppo in Finland.

Point forward

Nearly a decade on from its first electric product, Mirka’s black and yellow livery and squat bulldog logo can be found on the tool stations and in the work bags of thousands of tradespeople, and the design process begins very much with users in mind.

“Nowadays, we start the design process with a customer survey,” says Vasti. “We like to know how the customers see the products, how they use the products today, and we try to figure out the challenges that they have.”

These challenges differ from one product to the next: the Mirka tools portfolio has expanded to include electric and pneumatic sanders, polishing machines, dust extractors and tools for sanding walls and ceilings.

For its latest handheld tool, the DEOS (Direct Electrical Orbital Sander) Delta, the design is geared towards users working on interiors and furniture.

Built around a brushless orbital motor like the rest of the DEOS family, the Delta has been subtly redesigned to work better on softer materials like wood or plaster, where the user needs to get into the sharp corners of walls and cabinetry.

As a result, it has a peaked contact surface, shaped like a steam iron, in order to reach into tight spaces.

Concepts for the DEOS family tend to follow a pattern of early sketches that work around the form of the internal electrics and motor, but also analyse the way in which the user holds and moves the sander.

The DEOS Mirka sander is super lightweight, ideal for being held up against walls and panels for long periods without tiring its user. The ergonomic handle has a sprung palm trigger that also controls the speed, making it designed for single-handed use – valuable when the user is up a ladder and stretching to complete the last little bit of a job.

Overmoulded with rubber to help dissipate vibrations and provide grip, the domed handle forms itself around the motor and on top of the point where pressure needs to be applied for even sanding, while the compactness of the brushless motor means the hand is closer to the surface, giving precise control.

At its rear sits an easy-to-read user interface that is sealed to resist any dust ingress, along with a detachable (and therefore replaceable) power-in cord, and the vacuum hose attachment clip.

All these features of the DEOS family began with customer research in mind and Mirka’s designers sketching out where key internal components needed to be positioned, before the process moves into 3D, in order to begin making initial ergonomic concepts.

Designs move back and forth between digital on-screen and physical models, fine-tuning the scale and shape in the hand.

Mirka’s CAD software of choice is Solidworks, which Vasti praises for providing in a single package most of the features and functions that the company needs. A key benefit is the ability to quickly simulate a number of scenarios, both mechanical and electrical, from the CAD model within Solidworks.

Additionally, Mirka uses several proprietary electrical simulation packages on top of Solidworks, as well as vibration and noise level simulation, allowing the team to spot errors and make changes early on in the process.

Physical testing takes place in Mirka’s R&D lab, with rigorous electrical testing, as well as functional testing for casings and housings.

3D printing has come into its own at Mirka, with the design team making great strides to include the technology at all levels of design, testing and even in the production of end-use parts.

The company’s desktop 3D printers provide quick and cheap test model variants for early ergonomic form assessments, while its HP MultiJet Fusion 3D printer means that detailed functional test models and some small end-use parts are now built in-house, too.

“3D printing will change the way we design products, and help bring products a little bit earlier to market. It’s very useful!” says Vasti.

Mirka Sander – preparing for industry 4.0

Looking ahead, Mirka is betting on a future of IoT connectivity and workplace automation – and it is equipping its products accordingly. Its latest move in this area was the launch of its myMirka Dashboard, the brand’s own IoT system, which monitors the usage of power tools through an integrated vibration sensor inside the sander, and sends data to the user’s mobile devices via Bluetooth.

“It’s all moving more and more towards the digital element and big data that you can analyse a lot of things before they happen,” says Vasti.

This data is useful in a number of different ways. The person using the tool can be notified of vibration levels sustained, to help reduce the chances of them developing white finger. Company bosses can assess which tools are used the most, in order to assist with purchasing plans and to keep on top of equipment maintenance.

And for Mirka, this usage data can be fed back into the design process, because information on how different workers use the tools reveal opportunities for new products and improvements to existing ones.

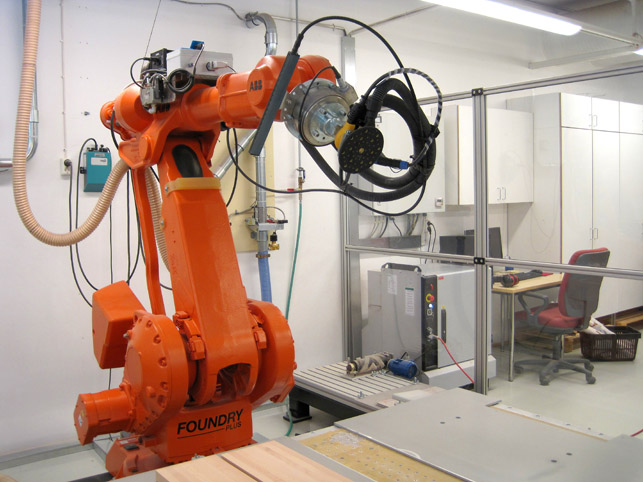

It doesn’t stop there, either: Mirka’s biggest customers are all making the move towards automation, says Vasti. “They are moving more and more to robotised sanding, so our portfolio and way of thinking needs to compliment it,” he explains, adding that this brings fresh design challenges.

With automation meaning that tasks need no longer be confined to human working hours, tools for sanding must be able to run for as long as the robots operating them, with as little downtime as possible.

“Everything has to be quality driven, because there can be no space for failure,” he says.

One thing that will remain, however, is the creativity of Mirka’s design team when it comes to producing products that open up new industries for the brand – from its 3-metre long handled LEROS model for sanding walls and ceilings, to its compact battery- powered AROS models for small car bodywork repairs.

Asked what is key to the way Mirka comes up with such ideas, Vasti replies: “We do not like to compromise. We like to make products that are really unique – that’s the way.”

With the global power tool market value predicted by some to reach $36 billion by 2025, Mirka’s user-focused designs, dustless technologies and unique abrasives look set to clean up.