Designed by Bond Bryan Architects and built on the site of the former Sheffield City Airport, Factory 2050 presents a 360 degree view of what’s going on inside

The Advanced Manufacturing Research Centre (AMRC) was formed in 2001 as a cooperative initiative between the University of Sheffield and Boeing. With Boeing having a requirement to provide work back into the UK following a Ministry of Defence order for both Apache attack helicopters and C17 cargo aircraft, the aerospace giant discovered that it could meet its requirements more efficiently by funding research and development rather than pure employment.

Established on the site of the Orgreave coking works in 2001, AMRC has, in the intervening time, expanded to become one of the UK’s (arguably the world’s) leading centres for advanced research into a wide variety of manufacturing processes.

Today, the AMRC campus spreads across the former industrial wasteland and encompasses a huge range of research, from composites to machining, from casting to additive manufacturing and all points in between.

The site is also attracting some big names in manufacturing who are looking to advance their production initiatives. Boeing is building its first European production plant nearby. Whilst supercar manufacturer, McLaren Automotive, is also in the final throes of building a new production facility next door.

No surprise that both of these companies along with 105 others, are partnered with the ARMC, all of whom fund specific research projects to solve their own challenges, but also contribute to general interest research that’s made available to all.

According to AMRC’s chief technology officer, Stuart Dawson, “The mission of the AMRC is to help improve the competitiveness of our members and we have a very good track record of achieving that. By applying these technologies and transferring them into industry, we’ve helped to secure UK jobs, attracted in investment and help companies perform more efficiently.”

Examples of how AMRC’s work has achieved this are widely available. From its work in helping Rolls Royce reduce the cost of manufacturing rotor discs on its Trent engine and so keeping production in the UK (resulting in a new factory in Sunderland) to its work in assisting McLaren bring the production of its carbon fibre tubs to the UK from Austria to help the automotive master achieve its production goals in the next years.

Factory 2050 has been founded to explore the potential for lower-cost, general purpose robotics

Enter Factory 2050

In the 16 years since its establishment, the AMRC has grown to cover not only machining and composites, but casting, nuclear research as well as training and apprentice focussed activities. Its newest initiative, Factory 2050, looks to combine this wealth of research and experience to present its vision for how the factory will look in 2050.

Factory 2050 is a new build on the site of the old Sheffield city airport and the Bond Byran designed facility opens up the production process of the future in a circular building, surrounded by glass.

While many might expect advanced manufacturing research to be conducted behind closed doors and keycard security, it’s clear that Factory 2050 is meant to show off what the future of manufacturing is going to look like and make it not only accessible, but attractive for future generations. But aesthetics and access aside, what are the teams and partners involved in this space looking to achieve?

According to Dawson, “Factory 2050 is meant to represent what we believe manufacturing needs to be like, to be competitive, in the year 2050; moving away from traditional, mono-tasking, fixed assets to a very flexible work environment that’s digitally enabled.

A factory that could take on products and industries with minimum expense – re-configurable, flexible and digitally led.”

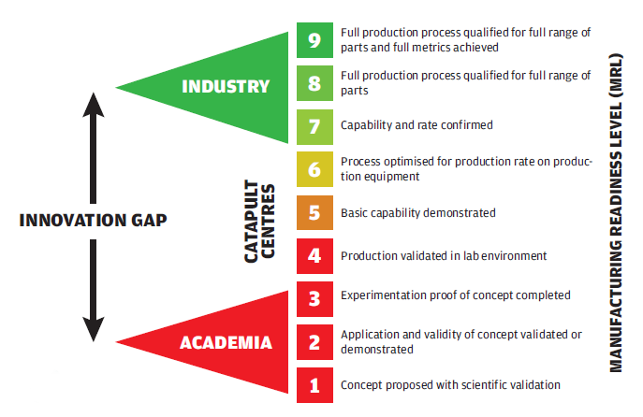

Manufacturing Readiness Level measures how a process moves from academic research into production

Four technology pillars of Factory 2050

Factory 2050 has four cornerstone technologies that its team and partners are focussed on to enable this vision to come to life.

Robotics and Automation is prevalent wherever you go. The team’s focus is to move away from expensive, high-value, specialist automation equipment to take advantage of the wealth of lower-cost, general purpose robotic equipment now available.

Each demonstration cell includes some form of robotics, from the high accuracy counter sinking operations on Joint Strike Fighter wing skins (which incidentally reduced capital investment for Boeing from £72 million to just £2 million) to the use of smaller scale robots deployed by a family-run Sheffield-based construction company, which was experiencing issues with an ageing workforce.

Another focal point is the use of integrated large volume metrology. This takes advantage of a wealth of measurement tools now available to assist with a wide range of tasks, to increase accuracy and ensure that large scale products can be completed in time (reducing rework by using in process metrology) and in tolerance.

Related to metrology is the use of digitally assisted assembly techniques. Here, a combination of smart products, smart assembly lines and a wealth of Internet of Things (IoT) enabled projects are looking to enable assembly lines to become not only more productive, but also more flexible. If data analytics can be used in combination with smart assembly tools as well as augmented reality display, it’s possible to have human operators become adept at switching complex tasks as their robotic counterparts.

One such example had a production cell, linked using PTC’s ThingWorx platform, to guide the worker not only through a process of ensuring they had all of the parts required to build a custom product (using IoT techniques along with smart parts racking and picking) but also guide them through assembly, feeding required torque information to a connected assembly tool direct from assembly work instructions.

The fourth pillar technology is Manufacturing Informatics. If there’s an overriding theme for Factory 2050, it’s the capture and reuse of data. Much of this is driven by machine level sensors. Feed that into an IoT backbone (built on Thingworx, no surprise given PTC’s tier 1 partnership) and ensure that the most is made of that data – whether that’s to assist capturing real time manufacturing information or feeding real time usage statistics and metrics to service engineers using an augmented reality headset.

Alex Godbehere, AMRC project engineer for the Integrated Manufacturing Group, comments, “ThingWorx serves a key role in Factory 2050 by collecting, processing and presenting data from multiple systems and information streams, allowing informed pro- active manufacturing decisions to be made.”

Factory 2050 is exploring the full spectrum of potential for the connected factory, whether that’s using IoT data fed to assist with production and assembly or using cutting edge technology to breathe life into legacy equipment to allow venerable, and often manual, machine tools to participate and provide valuable information in the connected age.

Augmented reality used in combination with smart assembly tools

Factory 2050 – Membership & company engagement

While it’s clear that Factory 2050 is looking to reevaluate how organisations approach manufacturing by encouraging and exploring the potential for lower cost and more flexible approaches to both production and servicing, it’s also clear that the team is aiming to expand the partnerships it engages with.

When manufacturers look at an organisation like the AMRC, there might be a pre-conception that it is reserved for the global elite manufacturers. However, this was something Dawson was quick to dispel.

At present, AMRC operates two levels of membership. Tier 1 is a premium partnership with costs of £200,000 per year. These members have individual seats on the board, which gives them an opportunity to influence the direction of future research. Tier 1 members can also propose specific projects to the board.

Tier 2 membership costs £30,000 per year. These members participate in, and obtain the results of, all generic projects, and are represented by a single board member.

In addition to advanced modern technology, Factory 2050 is exploring the potential to connect legacy machine tools via the IoT

Conclusion

With some incredible partnerships already underway, the AMRC’s world leading facilities looks to have branched out in an interesting manner as it explores how a more connected, intelligent and flexible factory might look now and in the future.

Previous project success at AMRC

Rolls Royce trent engine rotor disk

Rolls Royce was uncompetitive in the manufacture of these titanium components and was considering taking its manufacture offshore to Singapore. This formed part of the Rolls Royce Samuel Program with AMRC, who applied the techniques of dynamic analysis, cutting tool optimisation and operation reduction along with forging simulation to predict residual stress.

The combination of these reduced the time to manufacture each disk by 50% and on the basis of that, Rolls Royce built a new factory in Sunderland.

Messier-Dowty Ti 5553 landing gear

Messier-Dowty (now Safran Landing Systems) wanted to introduce a lighter material for the Boeing 787 landing gear using a special grade of titanium (Ti 555-3) but faced machinability issues compared to steel. By working with AMRC, it managed to reduce the machining time by a factor of 18 and a cost reduction of 30%.

This new, cost effective, landing gear resulted in Messier Dowty gaining the contract for not only the middle landing gear, but also the front. The first time a British company has supplied Boeing both sets of landing gear on an aircraft.

McLaren Automotive carbon fibre tub

McLaren Automotive has very ambitious plans to increase production of its road cars, up to 4,000 units per year. All of its products feature a carbon fibre tub, where the driver sits and these have been traditionally made in Austria using hand lay-up.

McLaren knew that if it wanted to hit its new production rates and move toward automation this had to change.It worked with AMRC’s Composites Centre to explore high-rate automated production. AMRC is currently aggressively maturing this process for when McLaren’s new factory opens.

We head to Sheffield to learn more about AMRC’s latest facility

Default