Beekeeping is undergoing a renaissance with many urban dwellers (including DEVELOP3D’s very own Tanya Weaver) joining the beekeeping ranks. Although new hives have come on the scene, a lot of the beekeeper’s tools are still very traditional and lacking innovation.

The brief was to redesign a piece of beekeeping equipment or design a completely new tool to add to the beekeeper’s toolkit that is user-friendly, sustainable, easy to manufacture and bee friendly.

Having whittled our entries down it was the Mister Bee Smoker that emerged as the bee’s knees.

The winner: Mister Bee Smoker by Product Resolutions

The concept combines modern technology with the use of traditional materials

Design consultancy Product Resolutions has designed a modern alternative to the traditional bee smoker.

The reason for using smoke is that it calms the bees making it easier to inspect the hive.

In a traditional smoker, fuel in the form of rolled up newspaper, smoke cartridges or twigs are lit inside the smoker. The beekeeper then squeezes the bellows causing the smoke to puff out the nozzle.

Although the Mister Bee Smoker still uses the familiar bellows method, it utilises ultrasonic misting technology to produce a cool white smoke.

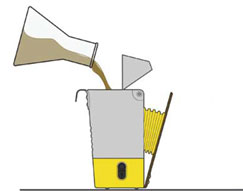

The beekeeper purchases liquid smoke sachets, which they combine with water before pouring into the smoker; a button is pressed and 30 seconds later the smoker is ready to use. The required amount of smoke is then puffed out through the nozzle, as it is needed, during the inspection.

Judges comments

There are a number of drawbacks to the traditional smoker including how much fuel to put in, controlling the rate at which the fuel burns (too hot and sparks can fly out) and then adjusting the amount of smoke that is emitted.

It’s a fine balancing act that can take quite a lot of experience to get right. Additionally, there is no elegant way to put the smoker fuel out once the inspection is over other than stopping the nozzle outlet with some green grass (not always available).

All of this is alleviated through the Mister Bee design and its use of cool liquid smoke, which is more user-friendly especially in built-up urban environments (if a beehive is kept on a roof terrace, for instance) as there is no chance of sparks flying out and anything accidentally catching alight.

It’s not a radical redesign of the traditional smoker as the bellows are still feature, yet the judges liked this sensitivity to old and new technology: although we want to move beekeeping into the 21st Century, at the same time we don’t want to completely exclude the more traditional beekeeper who is familiar with the its functionality.

It was a very clearly thought through project that was not just an exercise in styling. The designers had carried out research and consulted with local beekeepers regarding the requirements of a cool white smoke. The concept was very far along in terms of development as a rough prototype had been created in order to test the ultrasonic misting technology.

This was captured on video (below) and submitted with the entry, demonstrating that the concept is indeed feasible and could become a real product.

Prizes

Industrial Plastic Fabrications Limited (IPF) will produce a 3D physical prototype of the Mister Bee smoker. Product Resolutions will also receive a NVIDIA Quadro 2000 by PNY: a mid-range professional graphics solution with 1GB of GDDR5 memory

Mister Bee Smoker prototype test from DEVELOP3D on Vimeo.

Runner up: Swarm Catcher by Mike Luke

Swarming is a natural way for bees to create new colonies. There are means to control swarming but if the signs are missed, a colony will divide and the old queen with half the workforce will fly out the hive in search of a new home.

Before they find somewhere suitable, the bees will cluster around the queen on a branch, for instance.

When in this landing position, they can be knocked into a skep or cardboard box, covered and then taken to a new hive. But there is no guarantee that they will take to this hive and may swarm again.

The solution is the Swarm Catcher, a lightweight and easily transportable wooden box specifically modified to ensure a stable environment for the colony.

The bees can be directly knocked into the Swarm Catcher and the hinged roof shut. If this is done quickly and ‘en-masse’ it will ensure that the queen goes in and wherever she goes, the rest of the colony will follow.

The side hatch is then dropped to reveal a large opening with a queen excluder, which means that any remaining bees can come in but the queen cannot come out. Once the sun has

set and all the roving bees are inside, the hatch is shut and the Swarm Catcher can be taken away to its new location.

With many of the same features as a normal hive, including mesh floor, feeder hole and five frame capacity, the colony can remain in the Swarm Catcher until it has sufficiently expanded and is ready for a proper hive.

Judges comments

This is a very impressive solution to a problem all beekeepers will experience: swarms are not only detrimental to honey production, because essentially half the colony leaves when swarming, but the swarm can be doomed if it is not caught fast enough and ‘re-hived’ as domestic bees do not survive in the wild.

It is obvious that Mike Luke is a beekeeper or deeply involved in the beekeeping world as his design demonstrates a rich insight into a current problem. He also hasn’t redesigned or restyled an existing product but come up with something brand new that addresses a real need. A great deal of thought has gone into creating his solution.

The Swarm Catcher is also multi-functional as it can be used by a first time beekeeper to initially house a nucleus colony as it has all the features of a new hive. Mike Luke has also thought about all the little details such as ensuring the design has adequate ‘bee space’ and the fact that it can accommodate different frame designs.

It is a very practical solution that will not take a great deal to turn it into a marketable product.

Special mention: BPOD by Blake Mainwaring-Taylor

What impressed the judges most about the BPOD is not just the fact that Blake Mainwaring-Taylor is 12 years old and has been a beekeeper for three years, but his idea is actually very clever and well thought through.

This all-in-one device is attached to the beekeeper’s wrist and much like a utility belt, all the tools are inside and to hand.

Although it may be quite cumbersome to have all them inside one device as it will most likely be quite heavy, the fact that it incorporates a wearable smoker is a fantastic idea.

The storyboard demonstrating how his design came about, as well as the prototype he created to test his idea, was impressive. He also shows how it can be used and the benefits of having accessibility to the all the tools.

Special mention: The Beebuddy Smoker by Radius Creative

The beebuddy smoker operates much like a bicycle pump – the smoke pellets are lit inside and the smoke is then pumped out. To ensure that the airflow is in one direction only, the design incorporates a leather flap.

It’s all completely human powered, which makes it attractive.

Another benefit of the design is the fact that it’s compact and can be conveniently carried on the beekeeper’s shoulder with a strap attached to both ends.

This was also one of the only entries that really addressed the sustainability aspect of the brief. The materials used to construct the smoker are all sustainable and this was even extended to how it could be manufactured as the materials do not need advanced processing techniques.

Although there are reservations about getting enough leverage to pump the top part of the smoker, it was a valiant effort at creating a completely different mechanism for a smoker.

http://www.radiuscreative.co.uk/

Special mention: Buzz Smoker by Christopher R

Buzz Smoker is a nicely thought out electrical concept and with its stylish design would appeal to the young, urban beekeeper.

The flame is regulated by two fans that have three levels of speed.

An additional fan is placed near the mouth to blow the smoke out, so there is no reliance on the wind. After the inspection, the flame is put out by spinning the fan in reverse and so decreasing combustion.

The smoker is charged via a rechargeable battery underneath.

A number of CAD models showing the different aspects of the smoker, which had been created in Creo, were submitted. Not only were these impressive but so was the fact that he had entered a further two smoker designs into the competition.

Special prizes

Our three ‘Special Mentions’ will each receive an ‘Adopt A Beehive’, the initiative from the British Beekeepers Association that allows non-beekeepers to have a stake in a hive and receive regular updates.

Special Thanks

Many thanks to our competition partners:

– GRABCAD, the largest online community of CAD enigineers, for helping spread the word of our first design competition

– IPF, prototyping specialists and 3D printing bureau with the only Objet Connex 500 in the UK

– PNY for providing the amazing prizes of professional Nvidia graphics card to our winners

– The British Beekeeping Association, for assisting with advice and prizes

The Judges

The winning designs from our urban beekeeping challenge

Default