Cerebra – A custom riding helmet, created with the help of 3D scanning, has enabled a little girl to canter on in a sport she adores

Born 11 weeks early with spastic diplegia, a form of cerebral palsy, Imogen may not be able to run around with other children, but she can ride a horse. Riding horses has been a source of great joy to Imogen, but because she was also born with hydrocephaly, excessive swelling of the brain, her head is wider than normal.

That has made it challenging to find a riding helmet that will fit her. Every helmet she tried was either too big, and would drop down over her eyes while riding, or too small and therefore uncomfortable for her.

Despite the problem of ill-fitting helmets, Imogen’s love for and dedication to horse-riding has developed into real talent. She now participates – and excels – in dressage riding, making the search for a wellfitting helmet all the more urgent.

Frustrated by the lack of available options, Imogen’s mother Catherine turned to Cerebra, a charity that creates custom products for children with additional needs. Located at the University of Wales Trinity Saint David, the Cerebra Innovation Centre (CIC) has already made several custom helmets for children with hydrocephaly using 3D scan data.

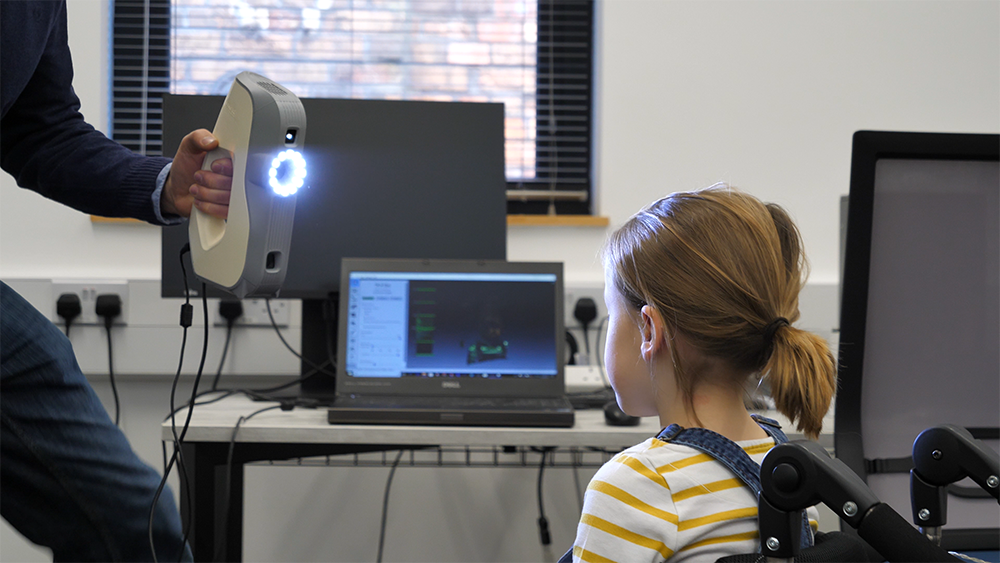

“The very first process was using the Artec Eva scanner,” says CIC design manager Dr Ross Head. “Once I saw what it could do, my mind began percolating with ideas on how we could make use of it in our work – and that’s when it hit me, the idea of using it to make bespoke helmets.”

The final design/production process clicked into place, he continues, when he hit upon the idea of scanning, 3D printing the moulds, fibre-glassing the shell and CNC machining the polystyrene liner.

Head was introduced to the idea of 3D scanning by the Assistive Technologies Innovation Centre (ATiC), with help from Artec reseller Central Scanning, and an accelerator project at the University.

The collaboration could be the first of many, as the partners aim to take their work further.

Once in CAD software, an offset of Imogen’s head was created, giving the exact dimensions for creating a precise 3D model that, in turn, was made into a perfectly fitting helmet.

“Imogen was curious about the Eva as it was scanning her face and head, and because it’s entirely safe, it wasn’t a problem when she peeked a few times during the scanning,” says Head. “She found it no struggle to hold still during the scan, which was over before she knew it.”

Post-processing gave the team at Cerebra an excellent basis for design

In terms of Cerebra’s process, after scanning and exporting to CAD, a two-part model is created. The inner polystyrene protective layer is exported for CNC machining and the shell model is used to create a 3D-printed (female) mould.

Once the inner surface of the mould is made smooth, layers of fibreglass and Kevlar are laid up using epoxy resin to make an extremely strong outer shell.

Subsequently, the helmet has been fully approved and certified by the British Standards Institution, validating the high level of protection it offers.

Cerebra’s firm belief is that, whatever children can dream, they should have the chance to try. That sees the organisation designing all kinds of special equipment for children with additional needs, so they can take part in events such as triathlons, surfing and even mountain climbing.

As for Imogen, she was happy simply to be back on her horse and riding again – and the team at Cerebra even put a silk cover in her favourite colour on her new riding helmet.