A Stratasys panel event discussed the drive to use 3D printing for end use parts

#1 The interest in 3D printing only gets stronger

The mainstream spotlight has long since moved on from 3D printing, taking with it consumer machines and the hyperbole, but the technology’s story has now entered a new chapter of enterprise.

No longer are we looking at printing parts and goods in our own homes; instead manufacturers from all industries and sectors are looking to enlist the benefits of now mature additive processes for their factories, and this means there’s a great deal of interest.

Attendance has nearly trebled (a staggering 1,700 people) since we first attended the event just three years ago, and the multiple-stream conference featured more diverse subject matter than ever.

With the likes of Carbon, HP, Stratasys and 3D Systems targeting end-use parts and large scale mass manufacturing, the landscape of the 3D printing market is stretching even further.

We found that the technology at mass production level finds itself with a chicken and egg conundrum: materials suppliers will only want to produce materials in large quantities, while users will only increase production if the right materials are available.

A materials development kit from HP sees the company trying to work with existing production materials suppliers, rather than attempting to do everything itself, leading to an exciting prospect – making materials development much cheaper and faster.

If it leads to the removal of this Catch22, it should see large scale adoption rocket.

#2 That doesn’t mean small printers are going away

On the small scale, Ultimaker made its first appearance at the event, seemingly after having had to state its case to the AMUG board.

Fair play to the organisers for vetting its exhibitors for quality over sheer quantity, but with machines of such ability as the Ultimaker 3, FormLabs 2 and the Markforged range, desktop machines are a tool that professionals would struggle to imagine life without.

Such is the segment growth, new printers such as the Rize One and Stratasys F123 series are specifically targeting the design office and prototyping bench sector with high-end machines built for product iteration, prototypes and low volume part production.

Equally, as far as bang for buck goes, having a raft of these on the production floor can be a money-saving wonder.

At Stratasys’ expert panel, Dr Phil Reeves, VP of strategic consulting within Stratasys Consulting, implored the audience to change their mind-sets in their drive for end use parts. Simple builds like jigs and fixtures should be 3D printed and used as enduse parts to huge cost savings over machined metal counterparts, and should be some of the first steps considered by companies looking to implement the technology in their production lifecycle.

Caterpillar spoke of how its scheme of distributing desktop printers on loan around its many US design and manufacturing sites formed a key method in educating its workforce, and allowing engineers and designers – instinctively creative people – to come up with their own ideas for what to print.

One of the many networking events at AMUG that allow for more informal discussion about the hot topics

#3 Heavily into metals

With established industry heavyweights and newcomers alike, you could barely move for the metals 3D printing companies at AMUG.

The presence of fresh faces Vader, 3DEO and Desktop Metal formed much of the conversation at the event’s large social sessions, where many of the attendees were looking to find out more about the various metals additive processes.

Most of the intelligent advice, of which the event had lots, directed these people to first uncover software solutions to help them to reconfigure and redesign parts, optimising them for the benefits the additive processes can bring.

Renishaw co-presented Betatype’s software tools for creating lightweight but strong metal foams, while Ntopology presented its guide to the metals process, and creating lattices and shapes that best work for additive technology.

Also causing a stir was the arrival of alternatives to direct metal printing, such as Markforged’s MetalX 3D printer, and Desktop Metal’s then still underwraps offerings, which in their own way print parts that, once post processed in an oven, are near full density metal.

With increased speeds and lower costs, these methods are going to be seeing a huge rise in interest in 2017.

#4 3D Systems freshens up

Having stepped away from the limelight in recent months, AMUG saw a resurgence of 3D Systems with a much clearer focus on industrial applications.

Still one of the biggest players in the entire 3D printing industry, and with a catalogue of technologies to prove it, the company wasn’t hanging back.

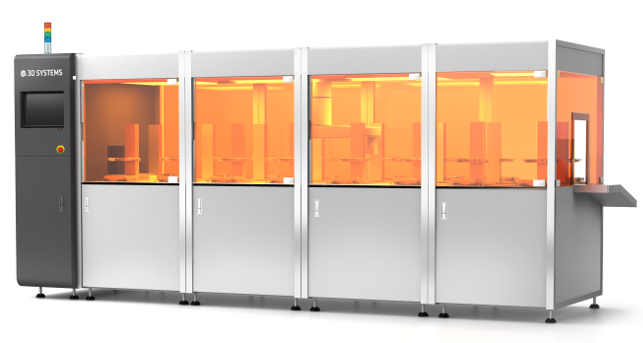

The event saw the launch of the Figure 4 production platform for plastic parts, a single ‘print engine’ 3D printer that can form part of an expandable, modular system comprising 16 or more print engines.

Vyomesh Joshi, president and CEO of 3D Systems, told us that the Figure 4 produces parts 50 times faster than comparable 3D printing systems, allowing it to target traditionally CNC machining-driven industries, such as dental, where it can reportedly print 20-30 crowns in less than 15 minutes.

However, the trick up the platform’s sleeve is the scalability of adding more print engines that could eventually produce customised consumer products in great numbers.

Additionally, AMUG saw the launch of two software platforms from 3D Systems.

3D Sprint and 3DXpert, for plastics and metals 3D printing respectively, prepare and optimise CAD data and then manage the additive manufacturing process.

3DXpert was particularly interesting. It packages up the entire additive manufacturing process, from importing part data, to optimising geometry and lattice creation; calculating the scan-path; arranging the build platform; sending it to the printer, and even machining the final product.

Sharing the same modern user interface design, both products were fresh faced and user focused – proving that 3D Systems as a whole seems to be reinventing itself.

3D Systems signalled its aim to produce more end use parts with the launch of its latest 3D printer, the Figure 4 production platform

#5 We need to see more designers

The majority of attendees that we met were day-to-day operators of 3D printers, from bureaux and in-house teams all over the US and further afield.

While many of the talks and presentations covered practical advice, machine know-how and showcased a lot of the latest features and abilities, it was the design elements involved that brought up the most intriguing questions.

This sparked the idea that, given the move to integrate more 3D printing into mass production, now is the time to encourage more education for designers about the abilities of the 3D printing machines and software out there. Even learning about some of the hands-on processes and machinery knowledge would be of benefit to even the most experienced design engineers, and AMUG would be an incredible place for that.

5 things we learned at the Additive Manufacturing Users Group

Default