If ever there was an industry in which time compression is the name of the game, it’s Formula 1 Grand Prix motor racing. Among the teams competing in Formula 1 is Scuderia Toro Rosso (STR), which is owned by the Red Bull Company. And like all other Formula 1 teams, STR is always looking for new and better ways to compress development and production times and to increase the reliability of its racing cars.

One advantage that the team has over the competition though is the use it makes of Geomagic Qualify 3D inspection software at its headquarters in Faenza, Italy. This has reduced the time required to inspect new parts by an average of 30 percent. It has also given STR the ability to inspect parts that previously could not adequately be inspected within the demanding time frames of Formula 1.

F1 team Toro Rosso used Geomagic technology to help driver Sebastian Vettel win last year’s Italian Grand Prix

Pierluca Magaldi, quality manager at STR, believes that in addition to the reduction in the time needed to inspect new parts, Geomagic Qualify has played a part in enabling the team to achieve the best result in its history last year. During the 2008 Grand Prix season the team earned its most points ever, its first pole position and its first win, fittingly at the Italian Grand Prix in Monza.

Wide-ranging inspection needs

Apart from the engines, which are supplied by Ferrari, around 35% of the components of STR’s F1 cars – including the chassis, rear crash structure, body shell and bonded aerofoil wings – are produced in-house. The remaining 65% – including light metal castings, machined parts and carbon fibre laminates – are produced by external specialists. Final assembly is done completely in-house.

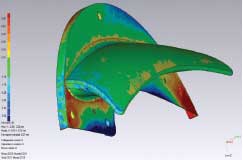

Front brake duct detail on a Scuderia Toro Rosso F1 car: Geomagic Qualify assigns a colour-map to the 3D model, with the different colours representing different degrees of deviation between the physical part and its counterpart 3D CAD model

“Production runs for our components range from one to maybe 30-40 for a complete season,” says Magaldi. “So we are definitely a prototype company, even though the prototypes we produce are used for racing.”

Before implementing Geomagic Qualify, the team used an outside company to inspect parts with complex shapes. Parts with less complex shapes were inspected in-house in the traditional way, using micrometers, vernier calipers and co-ordinate measuring machines (CMMs).

This traditional method required collecting individual measurements at specific points on the part. Those points would then be analysed for any deviation from the nominal as defined on the corresponding 2D part drawings. Inspection was therefore a long and laborious process and only a selection of points on the part could be inspected.

Today, the wide range of inspections carried out at STR starts with a Faro Laser ScanArm scanner and a Laser Line Probe to capture the shape of an object, be it a cast or moulded component, an aerofoil wing, or a casting pattern. The resulting ‘point cloud’ represents the bounding surface of the object to an accuracy of 35 microns. This point cloud is read into Geomagic Qualify to begin the inspection process.

“We still use CMMs for geometric dimensioning & tolerancing (GD&T) checks on machined parts where tolerances are set to a few microns,” explains Magaldi. “But in general, we use the scanner and Geomagic Qualify because the process is much quicker and allows the whole part to be inspected in detail, rather than just a few selected measurements.”

Simple, fast process

The inspection process relies on two inputs to Geomagic Qualify: the 3D scan data of the part to be inspected and the original 3D CAD model of the part from the team’s Unigraphics CAD/CAM system.

The first step is to create a single, unified 3D scan data model of the part by aligning and merging the individual scans taken from different viewpoints. The scans are aligned using automated methods provided by Geomagic Qualify.

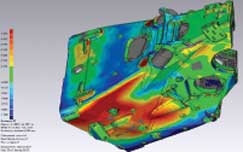

Gear box case on a Scuderia Toro Rosso F1 car

When the single 3D scan data model has been produced, datums and features upon which the inspection is going to be based are created on the CAD model. The scan data model is then aligned with the nominal 3D CAD model using both manual and automatic alignment facilities provided by Geomagic Qualify.

The whole process, from reading in the scan data and the CAD model to arriving at the point where the two models are aligned correctly and inspection analysis can start, takes no more than an hour or so to complete.

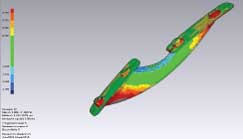

With the models aligned, the 3D scan data model is automatically analysed against the 3D CAD model to identify and measure any deviations between the physical part and its counterpart 3D CAD model, as well as for GD&T purposes. Geomagic Qualify automatically assigns a colour-map to the 3D model, with the different colours representing different degrees of deviation. Actual deviation values are also shown, along with GD&T call-outs.

Generally speaking, surface form errors at STR are 0.2mm maximum for complex shapes. If appropriate, whisker plots of cross-sections and wall thickness analysis results can also be calculated and displayed by Geomagic Qualify.

Inspection reports are then output as PDFs automatically and sent to the research & development (R&D) department and the design office for any remedial action. If any big non-conformities are discovered, the reports are sent to the original part manufacturer for action.

Benefits all round

At Scuderia Toro Rosso it’s all about maximizing results in the fastest time possible, so the first parts analysed by Magaldi and his team using Geomagic Qualify were those that had an effect on the aerodynamic performance of the car. These included the front and rear wings, as well as their corresponding patterns and moulds.

Today, the software’s use has been extended to just about every kind of part that is manufactured, either in-house or by third-party suppliers. These include cast, machined and carbon fibre laminate parts, as well as the patterns and moulds used to produce them. Because of the small batch numbers involved and the automation and speed provided by Geomagic Qualify, STR is now able to inspect every part produced for its Formula 1 cars.

Front wing support on a Scuderia Toro Rosso F1 car

Magaldi and his team have also gone beyond using Geomagic Qualify just to inspect individual components. It is now used in the assembly process as well to check, for example, the correct insert positioning for structural composite parts.

“There’s no doubt that the use of Geomagic Qualify has brought us a number of very real benefits,” says Magaldi. “For a start, we are now more confident that parts conform correctly to what was designed. We are also able to inspect parts that previously we couldn’t inspect fully, either because we didn’t have the technology or because of time constraints – or a combination of both of these. This gives us a better understanding of what we are going to assemble on a race car which will help towards better performance and reliability.”

www.scuderiatororosso.com

www.geomagic.com / www.faro.com

Inspection software and optical scanning make the grid for Toro Rosso