The exhibition is one of the most visited parts of DEVELOP3D Live

Looking back through all the videos we have created of talks at DEVELOP3D LIVE, it’s very clear to see the progression the industry has made in just under ten years.

Key areas such as Additive Manufacturing and VR have gone through the hype and overblown misunderstanding of the mainstream and have now become useful tools for product designers and manufacturers. CAD systems have become smarter, taking the donkey work out of complex geometry creation and speeding up ideation.

Software has gone from being functional and helping document ideas, to delivering near instant analysis results, connecting design teams, creating structures the human mind could never imagine and connecting to IoT sensors on physical shipping products.

This is what DEVELOP3D LIVE and the magazine is all about; the rapidly advancing toolsets available to creators to refine and push product design to better quality, more predictable outcomes and to revolutionise form.

This year, more than any other, the speakers at DEVELOP3D demonstrated that what is possible now, to everyone, from students to production engineers would have seemed like magic back at the first DEVELOP3D LIVE in 2010. Not only can we quickly model, test and optimise the performance of a prospective design, we can also use computing power to adjust the assembly or component to better suit the material, the production process or the budget.

With this being our first year at Sheffield we didn’t field our typical and hectic 47 speakers in four tracks in 7 hours and went for the more sedate, 30 speakers in three tracks: Mainstage, Additive and Design/Viz. With the addition of some new workshops, one by Brompton/Altair on design optimisation, and two relating to design IP – Potter Clarkson on IP in the age of Brexit and Randd UK concerning accessing tax credits for developing you own IP.

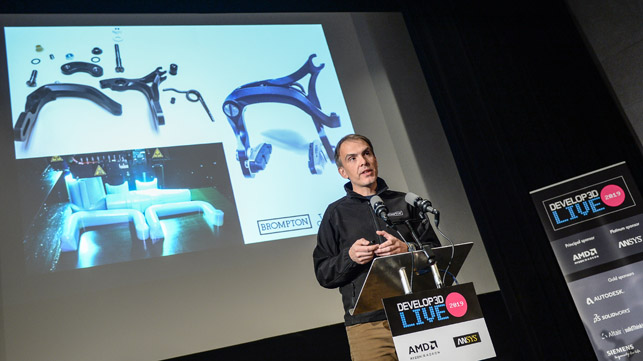

Brompton Bicycle’s Jonathan Heath explains how this iconic company is using simulation to great effect

VR was a hot topic for both this year and last year

Mainstage thoughts

Our keynotes this year were more down to earth than some of our previous talks, looking at more practical uses of available technology to just make existing designs better, with loads of knock on benefits. For the next month, a video of the keynotes will remain on the home page of develop3dlive.com, before being cut up and hosted on the DEVELOP3D YouTube channel.

Chris Harley of Wirth Research gave two great examples of where his in-depth knowledge of CFD and analysis from Formula 1 and racing car design benefitted Eddie Stobart in saving fuel, through using air-flow simulated and optimised body kits on its lorries to decrease drag and lower fuel consumption, providing great return on investment. Perhaps the least sexy product we have ever featured was a typical supermarket food chiller. These machines, which most of us never think about, are incredibly poorly designed and inefficient.

Wirth took on the task to redesign, and even fabricate a substantially more effective chilling cabinet using CFD to control the flow of refrigerated air, to stop spillage of cold air into the supermarket. This led to the design of an ‘Ecoblade’ to retrofit and manage the flow on old machines. The company then designed its own fridge which was 35%-40% more efficient than anything on the market, and then sold on the features to other OEM manufacturers.

Waitrose has jumped on-board; it’s finding the new chill cabinets save about 40% in electricity usage but also 40% of the whole store’s energy usage as less heat is required to combat the leaky fridges. Great stuff!

Jonathan Heath followed on and gave an indepth description of the manufacturing process at Brompton Bicycle, the UK’s design and fabricator of the world-famous Brompton folding bicycle, proudly hand made in the UK. Jonathan took us through the evolution and design enhancements that have typically been introduced in a very measured way, to maintain the shape and character of the bike but with new and improved technology.

Heath is committed to using the latest design optimisation and analysis tools to further refine the bicycles, improve ease of fabrication and design out weaknesses and flaws. For this he uses Altair’s suite of applications and he took us through a number of issues in which analysis of the design or fabrication method has resulted to improvements and reducing potential metal fatigue failures. This is a great practical approach to using analysis tools in engineering and well worth of watching.

The chance to get hands on with and talk to the folks behind the tech is one of the event’s main atttractions

Our future of manufacturing panel caused a heated discussion, but everyone ended up agreeing – sort of

Additive manufacturing track

It would’ve been hard to walk away from this year’s Additive Manufacturing track without having found out something new about 3D printing, or the way manufacturing as a whole is heading in the near and long term.

The varied array of talks opened up with new technology from Israel, with XJet showcasing its metals and ceramics 3D printing process, and news fresh from its test lab that it had successfully printed combined steel and zirconia parts.

There was no looking back from this point, moving between the future and the current – new materials, and exciting prospects, and present-day challenges and feats of ingenuity.

Betatype and GKN Additive gave us stories of how additive manufacturing solutions can be developed and are happening right now to produce end use customer parts, and how products of the future can benefit.

The realism of running an additive manufacturing facility today was brilliantly portrayed by Fluxaxis, with its look at what its business plan had projected, and the reality of where it fitted in to the supply chain.

The MTC gave an impressive look into how ramping up production is a case of more than simply packing more 3D printers into a room, and how its simulation studies and digital twins were quite simply the only way to predict and plan ahead.

‘Duck-sized’ satellites designed by the AMRC took us out of this world, while the presentation reminded everyone that, regardless of the masses of simulation done, physical testing of 3D printed parts is still needed.

The day’s proceedings were interspersed with a panel session; worth watching back online when it goes live on our YouTube channel, it proved that such things can be lively affairs. Despite the four spokespeople agreeing on much, the questions regarding the future of manufacturing saw them almost combative in their leanings.

While the audience learned an awful lot about what the future holds for additive manufacturing, the day proved that there’s still much to be decided, proven and built upon.

The audience spent the day dashing between busy sessions and exploring the exhibition

Exhibition

The layout of the main exhibition in the Octagon and Sheffield’s Student Union allowed the two exhibition areas to be a lot closer than in previous years. Our break-out rooms, for smaller talk sessions, were also quickly accessible from the main exhibition areas.

There were loads of new machines on show, from workstation class laptops to 3D printers, many hot new design tools, especially for fabrication and geometry optimisation and some incredible VR headsets. The Varjo headset struck me as a must see; it enables retina quality rendered images by tracking your eyes and rendering higher a density in the area of focus.

Summary

We had a lot of fun putting together this year’s DEVELOP3D LIVE and would like to thank Sheffield University for all its input, introductions and hospitality. Also, a big shout out to the staff at AMRC for enabling the tours the day before the event.

On the mainstage there were lots of speakers mentioning that engineering was undergoing a revolution and we concur.

The software has never been ‘smarter’, analysis never faster and nearly all vendors are bringing to market computational-based applications to optimise designs across multiple criteria, especially for additive manufacturing which requires new build methodologies. Computer Aided Design, is finally delivering on its meaning and not just helping to document ideas.

DEVELOP3D LIVE 2020 is taking place in Sheffield on 16 April – click here to find up more and register for updates