This appeared originally on maestros of 3D printing, Z Corporation’s blog a while ago and I’ve been wanting to repost it for a while and finally got hold of some better quality images from the lovely folks over at their HQ in the US.

The story revolved (ok – last pun, promise) around Andy Berlin, Senior Formware Engineer’s Groovy.exe project. Essentially, he developed a nifty little app that converts an audio file into a 3D printable surface. As someone with both an interest in 3D printing and the world of vinyl records, this is one story I couldn’t resist. So, here it is.

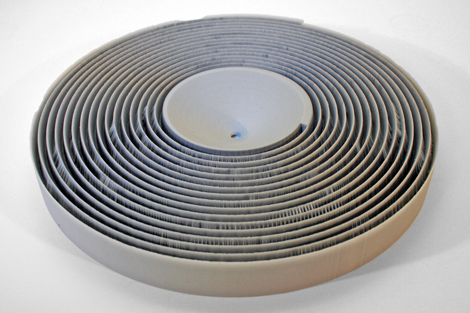

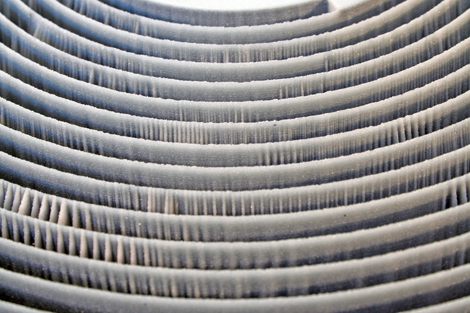

3D printing of appearance models is used to convey visual information. For this project, I explored a non-traditional way in which 3D printing could be used to encode information. I wrote a program that converts an audio file into a printable 3-dimensional model that vaguely resembles a record album, and hacked a record player to generate an audible signal from the printed model. Before getting started, a quick calculation revealed that for the resulting model to reasonably fit on a record player, the audio file would have to have 8-bit sample depth, limited by the .004” Z-resolution of the printer. And to play the record at 45 rpm, the best sample rate I could hope for out of a 10” diameter record would be about 6 kHz. The resolution would suffer even more as the record played, because the samples towards the centre of the record are closer together that those near the outer edge. This might work, but it wasn’t going to be high fidelity.

Version 1 of the program created a monochrome .STL file. The outer edge of each groove is smooth, to provide a surface for the tracking needle to ride along. The inner edge contains peaks and valleys which correspond to the audio data. In version 2, the program outputs a .ZPR file, where each sample is both coded by colour as well as height. High amplitude signals could then be lighter colour that low amplitude signals, further enhancing the signal for the optical playback mechanism. Craigslist provided a cheap, hackable turntable. The tone arm was modified to accommodate a 1” tall printed model. A pin replaced the needle to provide mechanical tracking, and an LED and optical sensor, remarkably similar to the LED/sensor module the ZPrinters use for auto-alignment, provided the playback signal.

While this modern version of a 45 may not be directly useful, perhaps it might inspire other creative or other non-obvious uses for 3D printing. If you’re wondering whether it was a success, well… if you listen really hard and apply the aural equivalent of squinting, you can just about hear over the noise the Beastie Boys belting out a rhyme from the 21 seconds of ‘Time To Get Ill’ that I printed.

Of course, it’s worth noting that the audio can’t be held in the video because it’s copyright, but in case you were wondering what it should sound like… Kick it!