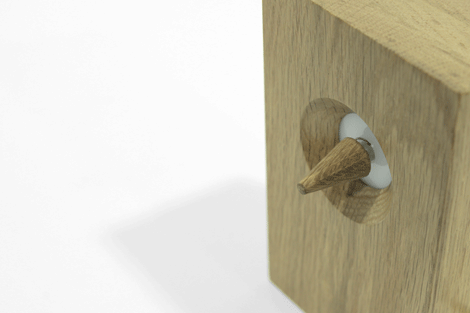

The Alarming clock’s mechanical bird beak raps out a ‘ready for sleep’ and ‘wake up’ alarm

Sleep can be a bastard, with restless nights causing groggy days and a cycle of frustration that can last for weeks, so why not have an alarm clock that not only wakes you, but prepares you for sleepy-time?

The Alarming Clock, designed by Natalie Duckett and Lee Murray, aims to help improve your sleep rhythm by introducing an evening alarm to notify you when to begin winding down in preparation for sleep.

Instead of sitting watching the brain-zapping blue light of your phone or tablet in bed, this proposed quiet time helps people develop a natural sleep cycle – notifying you 9 hours before you are due to wake up with the blissful sound of a beak drumming against wood.

Doesn’t look like your standard alarm clock

That’s right – the sound of a woodpecker – the alarm clock comes complete with a mechanical bird beak that raps against the surface you place it next to, making different sounds against different materials as opposed to the electronic squawk of your current alarm. It’s strangely soothing.

The original prototype was created in 2010 as part of Natalie Duckett’s final year design project at The University of Dundee. Initially, cultural studies were provided and sleep diaries were completed to help give direction to the project, by highlighting sleep related issues.

One main point highlighted was that no one on earth likes their alarm going off in the morning, so Natalie began experimenting with different methods by which sounds could be created.

To really change the look and feel of people’s expectations of an alarm clock, she then began working on crafting the Alarming Clock out of wood. Working from a sketch and moving it into SolidWorks, the form was honed through various prototypes made from cardboard, foam and wood.

The time itself is hidden from direct view (you need to peak under its base), which helps eliminate another cause of bad sleep – clock watching – and its touch-sensative controls means that its appearance is unlike any other alarm clock.

The final model is carved from a hunk of British oak, but Natalie still had to provide technical drawings of the final design from the SolidWorks model to the craftsmen who hand craft each unit, and to build the internal scaffolding to house the electronics.

Also, finding the correct craftsmen was incredibly difficult. “With the technology available, it is getting easier and more popular to build and design a product online,” explains Natalie. “With craftsmen, you have to search the yellow pages.”

As each outer shell is handcrafted there are slight discrepancies in the internal dimensions meaning each internal housing has to be made to measure.

Although sounding like a huge design flaw, the solution is built into design and the localised manufacture – using 3D printing to quickly modify and print out the correct sized piece to fit each shell perfectly.

Although mass manufacture would require a less costly and time-consuming manufacturing process, niche alarm clocks don’t really fall into mass consumer demand, which also adds to it’s unique nature.

The most difficult element to achieve was the circuit board: Lee had to learn how to design a robust electrical circuit that could withstand CE testing with no formal training, which by passing the regulations formed another huge achievement for the designers by keeping it all in house.

The end product looks and sounds unlike any alarm clock we’ve seen before, more charming that the current hunk of plastic adorning the standard bedside table, and another step in removing smartphone dependancy with its sleep-wrecking pre-bedtime blue light.