CGTech’s Vericut 9 CNC simulation, verification and optimisation software was released earlier this year but continues to be improved and enhanced with additional incremental releases since.

If you missed it, Vericut 9 brought sharper displays, clearer views of the cutting process and better utilisation of system resources, making it easier to spot problems and imperfections in machined parts. It runs a lot of operations multi-thread and makes use of any GPUs present that previous versions didn’t do.

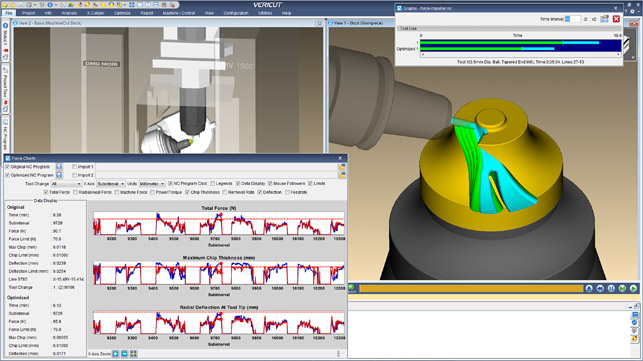

The new OpenGL-based display improvements mean users get optimal performance running simulations in a single view or multiple views, allowing them to switching between workpiece, machine, or profile views.

It also means that you no longer need to run individual views to perform operations, such as running a machine simulation, cutting a section while it’s running or using Vericut’s built in measurement tools (such as X-Caliper and Auto-Diff) in the same window.

There has also been work done to automate commonly used functions and workflows. For example, it’s now possible to check cutting limits, spindle direction, coolant, syntax and tools by setting the checks up in master templates so Vericut runs them automatically.

CGTech’s Vericut 9 CNC simulation, verification and optimisation software’s raison d’être is to find issues with your machine toolpaths in a holistic manner – not only simulating the cutting (as is common in most CAM systems) or the movement of the machine tool, but rather running everything independently from your CAM system (hence, verification, rather than simulation).

Optimising verification times & Force

Of course, this is a more complex process than pure simulation and can be computationally expensive – to speed things up, Vericut 9 allows the user to quickly preview programs running with actually cutting the part, allowing you to find machine crashes, fixture crashes and travel limit errors.

Any issues founds are stored in the Vericut logger and clicking the error it takes you directly to the block in the NC program where the error occurs where changes can be made.

Using the new Restart function there is no need to verify from the start. Just verify the NC code from the line where changes have been made. This will be a huge benefit anyone verifying larger than average NC programs.

As well as simulation and verification enhancements, Air-Cuts only optimisation allows users to optimise tool motions that are not in contact with material with. This is included in verification, it’s easy to use and it runs while simulating.

For more advanced optimisation, the Vericut Force module comes with enhanced charts for analysing cutting conditions, chip thickness and tool deflection (there’s more on Vericut Force in our review from a while back).