Smit Röntgen has spent the last 10 years developing its Tungsten 3D printing process

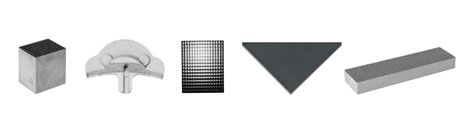

Philips-owned company Smit Röntgen has announced its ability to 3D print pure Tungsten parts – the metal with the highest melting point of 3422°C.

Imaging component manufacturer Smit Röntgen has been developing the process over the last decade, and has now opened the lid on its process that through laser melting technology can produce solid parts from this tricky material.

The downside is that a minimum of 48 hours is required for a CAD model to be transformed into a solid product, yet the interest that this will create in the aerospace and medical industries should see this development time drop further in time.

The material properties of Tungsten, including its 3422°C melting point, are desirable for the medical and aerospace industries

Pure tungsten is an excellent X-ray absorber, is resilient to high temperature exposure, and is environmentally safe (the all important RoHS compliant). with the technology enabling high volume production of tungsten parts without design compromises.

“When talking to major players in medical and non-medical fields, it becomes evident that being able to 3D print pure Tungsten parts does attract global attention. By mastering this technique, the possibilities for creating new innovative products and niche markets are endless,” explains Pieter Nuijts responsible for marketing and sales at Smit Röntgen.