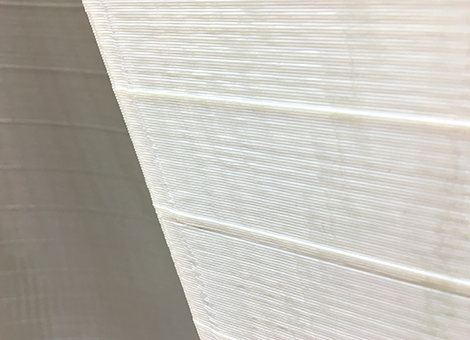

Stratasys will talk more about the giant part printing ability its latest Infinite Build Concept 3D printer

Industrial grade 3D printing for end-use parts – of all sizes – will take centre stage at DEVELOP3D LIVE Boston on September 26. Hear from those changing the future of manufacturing and find out how it can change the way your team is designing.

From desktop machines to those building infinite-sized parts, 3D printing is changing beyond what we already know, and this is your chance to find out more.

Highlights include:

– Stratasys is aiming big in aerospace, automotive and other industries with the Infinite-Build 3D for large, lightweight, thermoplastic parts with repeatable mechanical properties. SVP Jon Stevenson will reveal all.

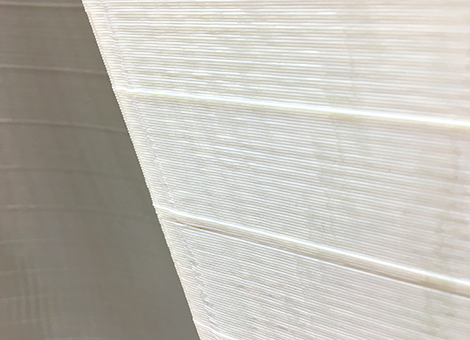

– The Markforged Mark Two 3D prints parts with the ‘strength of aluminum’. Hear from CEO and Founder Greg Mark about customers who are uncovering real value from printing strong end-use parts.

Composites printing on the designer’s desktop with Markforged

– Rize’s Augmented Polymer Deposition (APD) technology takes engineering-grade thermoplastics and changes the material properties with functional inks down to the level of a voxel (3D pixel). President and CEO Frank Marangell will explain how to deliver robust injection molded-like parts 50% faster and at lower cost than other technologies.

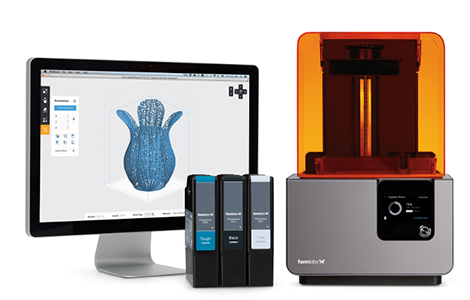

– Dávid Lakatos, Chief Product Officer at Formlabs will present a new take on stereolithography (SLA) technology, making which is claimed to deliver achieve industrial-grade print quality at a fraction of the cost.

FormLabs, from start-up story to leading lights of the desktop SLA machines

– Open Source 3D print manufacturer Ultimaker will be showcasing its latest desktop machine for functional prototypes, end-use parts and tools that require high-performance properties like toughness, strength and chemical resistance.

– Meanwhile, Xometry delivers a whole raft of manufacturing services on demand through its dynamic network of US partners. Think CNC Machining, 3D printing, sheet metal, and urethane casting and more.

DEVELOP3D LIVE Boston takes place at District Hall, Boston, USA on September 26 – Find out more and grab your tickets here.