More and more designers and particularly engineers, are becoming involved with the creation and editing of highly complex shapes. Today’s consumers don’t want staid, boring products and those responsible for design of even the most industrial or functionally led products are having to differentiate their offerings using organic and often complex shapes (there’s a good post on the subject on the PTC blog about the same subject).

The problem arises in that creating complex shapes is traditionally done using surface modelling technology – an inherently complex process where each face or form is creating from splines and individual sketches and geometry sets. If smooth transitions between faces are required, not only just each surface work in it’s own right, but the transition (whether tangency or curvature continuous) must be established. This means that not only is expertise required to create it, expertise is required to edit it in a meaningful way.

What this leads to is a heavy investment of time to construct a parametric model to define a form. Because of that time investment, many users are reluctant to make heavy edits to it for fear of breaking it – and so the design process gets bogged down at a very fundamental stage when it should be at its most free and unencumbered.

So is there something else that can be used? The answer is perhaps sub divisional modelling techniques. Looking the term up on wikipedia and you get:

A subdivision surface, in the field of 3D computer graphics, is a method of representing a smooth surface via the specification of a coarser piecewise linear polygon mesh. The smooth surface can be calculated from the coarse mesh as the limit of a recursive process of subdividing each polygonal face into smaller faces that better approximate the smooth surface. Source: Wikipedia

What does this mean in plain english? My take is something like this:

Sub divisional modelling lets you create complex, freeform shapes by manipulating the geometry using a series of points, edges and faces of a cage that surrounds the resultant geometry. You pull, you push, you add detail and you’re done. In comparison to traditional surface modelling, there’s much less dicking around. Source: Ummm.. me

AdvertisementAdvertisement

So where are the tools?

Given that sub-D modelling methods are pretty well established, you’d be forgiven for thinking that these types of tools are common place. After all, the ability to knock out a series of concepts in a very short space of time is shear, unadulterated good thing, right? Absolutely, but the level at which these types of tools have been integrated into our workhorse tools is limited.

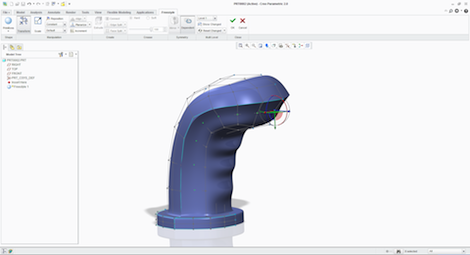

One of the most interesting examples is the new Freestyle feature found in Creo 1.0 and extended with the forthcoming Creo 2.0 release (due in the next few months). This builds sub-d modelling tools right into the heart of Creo (formerly and still pretty much, Pro/Engineer) so let’s have a quick look at what it can do.

Sub Divisional modelling, as found in Freestyle, allows the creation and editing of highly complex forms using a very freeform method of interaction. A primitive is created (from a variety of stock forms – planes, spheres, cylinders), and a controlling “cage” is used to manipulate that form. It’s not organic modelling per se, but rather a controlled form where curvature continuity is maintained (essentially without any interaction on the users part) and forms can be created very quickly. Throw a sphere in, drag and drop, add more material using the extrude option, add auto-mirroring if you’re working on a symmetrical concept, tools to flatten to a plane, adjust the sharpness/influence of a point or edge, add a crease. It’s all there and growing with the 2.0 release.

Who else is doing it?

Within the ‘mainstream’ CAD space, there’s historically been very little other movement in this direction, though things might be changing. Dassault has had the Imagine & Shape technology within Catia for sometime, but few have been able to get their hands on it due to the cost of the system and the prerequisites.

t-Splines (which is a form of sub-D that I won’t go into) was perhaps the best known as a 3D design app solution, built into both Rhino and SolidWorks held the greatest hope, but its since been acquired by Autodesk, so it’ll be interesting to see how this tech makes it into the Inventor release (I doubt it will be for the imminent 2013 stack).

Luxology’s Modo for instance, is a prime example of a system that while not initially targetting the 3D product design space, has seen adoption for this very reason. Its sub-D tools are perfect for generating concepts and progressing things further, backed up with all those rendering and animation tools that we love the guys at Luxology for. Here’s Mr CADjunkie himself, Adam O’Herne showing what it can do.

A new dawn?

We’re all aware that 3D modelling is an inherently complex business. You’re defining a shape, from your imagination, in a computer. That’s always going to be a little more difficult than typing out words. But does that mean the tools themselves should be hard to use? No, it does not.

3D CAD is, particularly for those that have grown up using it, is a way to conceptualise a product and I’ve come across many designers that can knock up a quick model in the same time it takes some to draw out a sketch with a pad and pencil. There’s nothing better about either approach, its just a case of what works for the user.

The problem is that many of today’s tools for complex shape creation are overly complicated in their use model. Do we really have to rely on 3d sketches, work-planes, creating and struggling to maintain curvature, form correct four sided patch networks still? In many cases, yes. And let’s be clear, at that stage where you want the high quality, ultra formalised surface model, there’s still a place for these traditional methods.

But if you want the freeform thinking, the ability to have an idea in your mind’s eye translated into a geometric model, then sub-d surfacing is perhaps the easiest route to get that done. It also aids experimentation.

A sub-D based model isn’t as heavy (in terms of creation and more importantly, editing), because an entire product’s A surfaces can be held within a single feature. You don’t need to know what you did last time, you dive in, edit, push, pull, tweak and see where you get to. Because of that lack of effort required to edit the model, there’s less investment of effort to make changes, to adapt to new ideas or try a new concept. That means you don’t get stuck on a singular track during the formative stages of design when it should be at it’s most free and unencumbered.

The good news is that these tools are becoming more widely known and more widely adopted by the developers, so we’re getting access to them. And some say CAD is done. As we’re all aware, that’s nonsense. Whether it’s a standalone tool like modo (and there’s some details about a sweet sounding fix for this on the EvD podcast with Luxology’s CEO Brad Peebler engineervsdesigner.com/brad-peebler), whether its an integrated approach like Catia’s Imagine & Shape or Creo’s FreeStyle, these tools represent a step change and something that’s worth of exploration. I’d love to hear what you think, for good or bad.